Screen printing has been around for centuries and is still a popular way of producing detailed prints on various surfaces. One key aspect of this practice is the emulsion, which is vital for transforming designs into stencils for screen printing. But what is screen printing emulsion?

The article will define screen printing emulsion and provide information on its properties, which help with the printing process.

What Is Screen Printing Emulsion?

Screen printing is the process of transferring designs onto surfaces like clothing or posters. It is a process that comprises artistry, precision, craft, and having the right tools and materials.

Artists have used this method for a long time. It has also found its place in marketing and various businesses as a means of creating promotional materials and branded merchandise.

So, what is screen printing emulsion used for? An emulsion is a photosensitive substance used in screen printing that allows for the design to be turned into a stencil. This material gets applied to a mesh screen to create a blank canvas where the ideas can be applied.

Then, after getting exposed to UV light in a particular pattern, the emulsion reacts by hardening while the unexposed areas remain water-soluble.

Understanding Screen Printing Emulsion

To better understand screen printing emulsion, it’s important to learn the various segments that make up its composition and its pivotal role in the printing process. Moreover, its chemical properties, such as sensitivity to UV light and how it reacts during exposure, are key to understanding what screen printing emulsion is used for.

So, we at Thrive Screen Printing aim to reach the ultimate excellence in the screen printing industry. We have the capacity to answer your high-volume demands with the highest quality and on-time delivery. If you are looking for the best Arizona screen printing for large businesses, we are happy to help!

Composition

Screen printing emulsion is a type of coating that creates the stencil, i.e., defining the areas where the ink will pass through during the printing process. At the same time, it must block the areas where ink is not intended to transfer, resulting in precise and high-quality prints.

What is emulsion in screen printing made of? Its composition consists of a polymer base and a photosensitive sensitizer, which create a light-reactive chemical compound. It is also made of several substances, including acrylic resins, pigment, and photoinitiators. The resin acts as a binder, the pigment provides color, and the photoinitiators activate the emulsion when exposed to light.

Types of emulsion

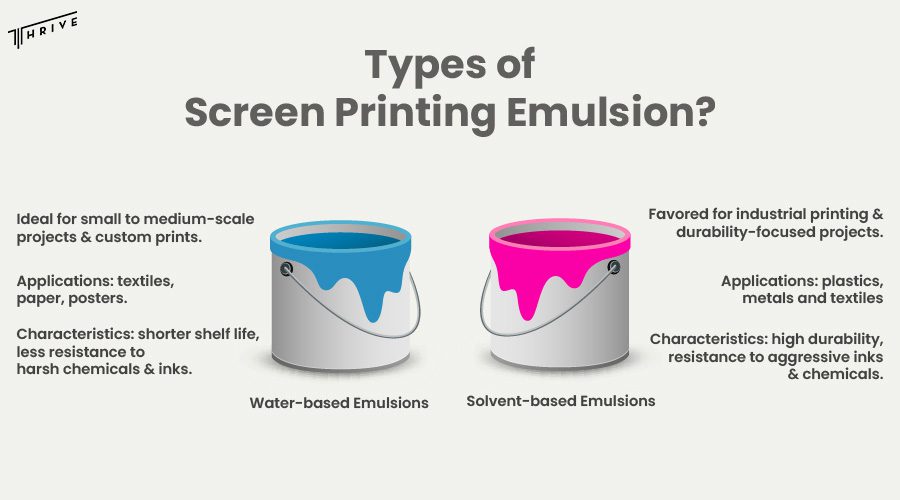

Emulsion can come in different types, and each has its characteristics that make it suitable for specific operations. The two primary types used in screen printing are water-based and solvent-based emulsions.

These types have unique advantages that make them suitable for different screen printing tasks. They have in common the core function of creating stencils via reacting to UV light, as they both have photosensitive properties.

However, they differ in the composition of their bases, with water-based emulsion using a water-soluble polymer and solvent-based emulsion relying on organic solvents. These differences result in variations in their suitability for different projects.

Water-based emulsions are more suitable for small to medium-scale projects and custom print jobs that involve printing on textiles, paper, or posters. They may have a shorter shelf life and are less resistant to harsh chemicals and inks.

On the other hand, solvent-based emulsions are more durable and resistant to aggressive inks and chemicals. This makes them more suitable for industrial printing and projects where durability is prioritized.

How to Use Emulsion for Screen Printing

The screen printing process requires creating a stencil that precisely matches the design. The stencil guides the ink, allowing it to pass through specific areas while blocking it in others.

Hence, making a high-quality stencil is crucial for achieving a detailed and accurate print. Mastering the stencil-making process requires attention to detail, precision, and technique to ensure that the screen accurately represents the design.

Furthermore, the emulsion gets applied to both sides of a clean and dry mesh screen. Usually, this is done in a dark environment to prevent the emulsion from reacting to the light. The surface needs to be even and smooth, and the goal is to create a uniform layer across the entire screen.

Next, the emulsion will dry up in a few hours, which is when the design should be applied to the screen. The design needs to be opaque, meaning that it blocks the light from passing through and should be inverse of the final print.

Then, the screen gets exposed to UV light to harden the emulsion in the areas designated by the design. The unexposed areas will remain soluble and will be easy to rinse off with water to form the stencil.

Removing screen printing emulsion

You can completely remove the stencil from the screen if you intend to use it again for a different design or if it needs to be refreshed after being used several times. Once exposed to UV light, the emulsion becomes more difficult to remove and requires the use of substances and tools.

Additionally, you may require emulsion removers, pressure washers, and scrub brushes to remove the emulsion from the screen. So, apply an emulsion remover on both sides of the screen to break the hardened emulsion down and soften it before removal. It’s important to allow the remover to rest for a few minutes to maximize its effectiveness and dissolve the emulsion.

Then, rinse the screen using a pressure washer and scrub it with a brush to remove the emulsion. You must dry the mesh screen entirely before applying emulsion to it again.

Doing this procedure will save screen replacement costs and reduce waste. It’s particularly helpful for screen printers who have to change their designs frequently because they work on many different projects.

Conclusion

What is screen printing emulsion? In screen printing, the emulsion is a photosensitive substance that reacts to UV light exposure in the way the printer makes its design. There are water-based and solvent-based emulsions that have different applications.

When exposed to UV light, the emulsion hardens and, after washing off the non-exposed areas, creates a stencil where the ink will go later. Also, mesh screens can be reused if the emulsion is washed away properly.

So, if you require the best screen printing services, contact us!

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.