Have you ever wondered how that eye-catching design on your favorite T-shirt or the intricate pattern on a poster comes to life? It’s the magic of screen printing, an art form with a rich history and its hand in many industries. But how does screen printing work?

It’s been around for centuries and has a rich history in art, industry, and even DIY projects. This process allows the creation of intricate and colorful designs on materials such as textiles, paper, glass, and even circuit boards.

So, we’ll discuss screen printing, unraveling the process while revealing its artistry. By the end of this article, you’ll have a solid understanding of the art and science behind screen printing and appreciate its role in both creative endeavors and industrial processes.

How Does Screen Printing Work?

Screen printing is a printing method that involves pushing ink through a stencil (screen) onto a surface, creating detailed designs. It begins with screen preparation, stencil placement, as well as ink application and ends with drying and curing.

When the screen is exposed to light, the stencil allows light to harden a photosensitive emulsion on the screen, creating the design. This versatile technique is prized for its durability and vibrant results, finding applications in diverse industries.

The Screen Printing Process

Screen printing might seem like magic, but it’s a systematic process that involves specific materials and equipment. Let’s break it down step by step in a friendly and easy-to-understand way:

1. Materials and equipment

Screen

This is the heart of screen printing. It’s a frame with a mesh stretched over it. The mesh holds your design in place and allows ink to pass through where it’s supposed to. Screens come in various sizes and mesh counts, depending on your project.

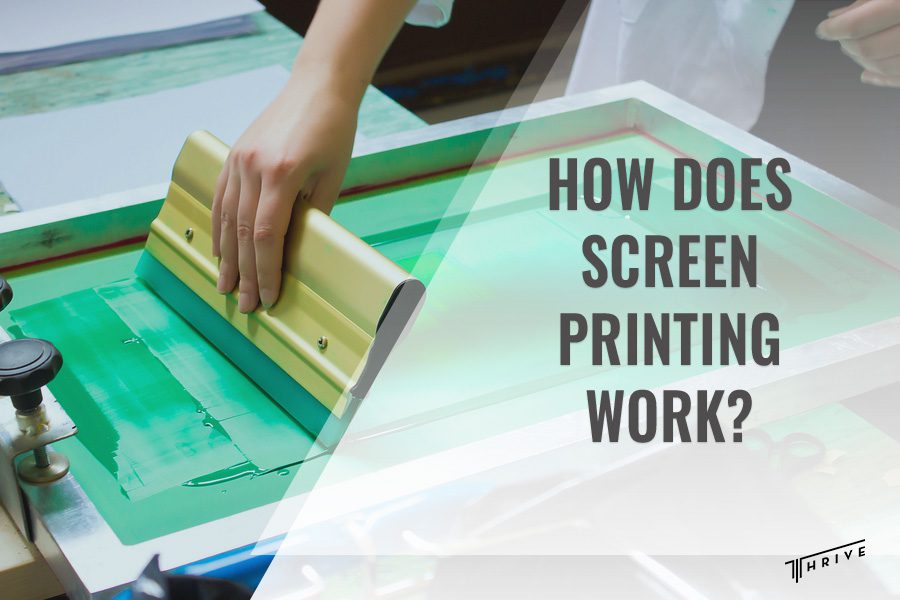

Squeegee

The squeegee is like a magic wand in screen printing. It’s a rubber blade that you use to push the ink through the screen and onto your material. The pressure you apply with the squeegee determines how much ink goes through, so it’s a crucial tool for getting the right print.

Ink

Ink is where the color and magic happen. There are different types of ink, like water-based or plastisol, each with its unique characteristics. You choose your ink based on what you’re printing on and the effect you want to achieve.

Substrate

This is the fancy word for your printing material. It could be a T-shirt, paper, glass, or something else. The choice of substrate affects how the ink adheres and looks.

2. Preparing the screen

Mesh selection

The mesh on your screen isn’t just any mesh; it’s carefully chosen based on your design and the material you’re printing on. The finer mesh works for intricate details, while the coarser mesh is better for bold designs.

Emulsion coating

To create your design on the screen, you need to apply a light-sensitive emulsion. It’s like a photographic negative that hardens when exposed to light. Once it dries, your design is locked in.

Image exposure

Here’s where your design gets “burned” onto the screen. You have to place your design (a stencil) on top of the screen and expose it to bright light. The emulsion hardens wherever your design allows light to pass through, creating your print template.

3. Printing process

Ink application

Now, it’s time to bring your design to life. Lay your prepared screen on the material you want to print on. Then, pour ink onto the screen just above your design.

Squeegee action

Here comes the fun part. Use the squeegee to press down on the screen and pull the ink across it. The ink passes through the parts of the screen where the emulsion has hardened (your design) and onto the material below. And, you’ve got your print.

Multiple colors and layers

You repeat the process with different screens and inks for designs with multiple colors or layers. Each layer adds depth and complexity to your final print.

4. Drying and curing

Once you’ve printed your masterpiece, you must let it dry. You can do this naturally by letting it air dry or use special equipment for a quicker process. After drying, the ink is still delicate, so it needs curing, often done by applying heat. This makes the ink bond permanently with the material, ensuring it lasts.

5. Cleanup and maintenance

Don’t forget to clean your screen after each use. Removing any leftover ink and emulsion is essential so your screen is ready for your next creative project. Additionally, proper maintenance ensures your equipment stays in good shape and is ready for many more prints.

Advantages of Screen Printing

- Durability – Screen printing produces incredibly durable prints. The ink bonds well with the material, making it resistant to wear and tear, frequent washing, and exposure to the elements.

- Vibrant colors – This technique allows the use of vibrant, opaque inks that result in bold and long-lasting colors. The colors remain vivid over time.

- Versatility – Screen printing is highly versatile, accommodating various materials, including textiles, plastics, and metals. It adapts to a wide range of applications.

Disadvantages of Screen Printing

- Setup time and costs – Screen printing can be time-consuming and costly to set up, especially for small runs. Creating screens and preparing the equipment requires an initial investment of time and resources.

- Complexity of multicolor prints – While screen printing can produce multicolor prints, each color requires a separate screen and passes through the press. Complex designs with many colors can be labor-intensive and challenging to align perfectly.

- Environmental concerns – Traditional screen printing involves the use of chemicals, such as emulsions and solvents, which can have environmental implications. However, efforts are being made to adopt more sustainable practices in the industry.

Modern Innovations and Technology

Digital screen printing

Digital advancements have revolutionized screen printing. Digital screen printing machines enable faster setup and are ideal for short runs. They offer high-resolution prints and greater design flexibility.

Automated screen printing machines

Automation has streamlined the screen printing process. Automated machines can handle large volumes, ensuring consistency and reducing labor costs. They are advanced equipment used in the printing industry to efficiently and precisely apply ink or other printable materials onto various surfaces, including textiles, paper, plastics, glass, etc.

Sustainable practices in screen printing

To address environmental concerns, the industry is adopting eco-friendly practices. Water-based inks and environmentally friendly emulsions are becoming more prevalent, reducing the environmental impact.

Integration with other printing techniques

Screen printing often complements other printing methods. Hybrid printing systems integrate screen printing with digital or offset printing, allowing for intricate designs and vibrant colors in combination with high-speed production.

Frequently Asked Questions

What is the principle of screen printing?

Screen printing operates on the principle of using a stencil or screen to selectively block out areas where ink should not pass through, allowing ink to pass through the open areas onto a surface.

The stencil, or the screen, is prepared by applying a photosensitive emulsion that hardens when exposed to light. When this emulsion hardens, it creates a template or design. During printing, ink is pushed through the open areas of the screen onto the material, creating the desired design or image.

Is screen printing durable?

Yes, screen printing is renowned for its durability. The ink used in screen printing forms a robust bond with the material, resulting in a print that is highly resistant to wear, washing, and exposure to environmental factors such as sunlight and moisture.

This durability is one of the primary reasons why screen printing is often chosen for items that require long-lasting and high-quality prints, such as clothing, banners, and industrial products.

What is the name of the cloth used in screen printing?

The material stretched over the screen’s frame in screen printing is typically referred to as “mesh.” The choice of mesh material can vary and may include options like polyester or other synthetic fibers.

Historically, silk was used, so screen printing is sometimes called silk screening. The selection of mesh material depends on the specific application, the desired level of detail, and the type of ink being used. Different mesh materials offer different levels of durability and are suited to various printing tasks.

Conclusion

We’ve delved into the fascinating world of screen printing, uncovering its intricate process and artistic potential. So, how does screen printing work?

Screen printing is a multi-step process that begins with creating a stencil or screen. This stencil, created by applying a photosensitive emulsion, determines the design to be printed. Then, the screen is placed over the material to be printed, and ink is applied to the screen’s surface.

Next, a squeegee pushes the ink through the open areas of the stencil, transferring the design onto the material below. After printing, the ink is cured or dried to ensure it adheres permanently to the surface.

This age-old technique, celebrated for its durability and versatility, continues to captivate many industries, while modern innovations promise an exciting future for this time-honored craft.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.