In the ever-evolving textile industry, screen printing stands out with its versatility and vibrant results. We mastered this printing technique over the years, adapting it to meet the needs of our diverse clientele. We often face intriguing queries, and many of our customers have questions like: can you screen print over a screen print?

This article explores the possibilities and complexities of layered screen printing and helps demystify the creation process of multi-layered prints. It sheds light on the feasibility of printing over existing screen prints, offering valuable insight into the process and its possibilities and limitations.

Can You Screen Print Over a Screen Print?

First, it’s essential to have a fundamental grasp of screen printing. This printing process involves pushing ink through a mesh screen onto a substrate, be it fabric, paper, or another material.

This technique dates back to hundreds of years ago and is mainly favored due to its versatility, durability, and vibrant results. At Thrive Screen Printing, we honed the craft of high quality screen printing to adhere to a diverse clientele.

However, it is only natural to ask: can you layer screen printing? Mistakes often happen, and letting good material go to waste can be a shame and a financial loss. So, the answer is yes, but not with all caveats.

Although screen printing is feasible, its success depends on several factors. We need to mention that reprinting over an existing print relies on the multi-layered screen printing technique.

The key to success in multi-layered screen prints is precision. It ensures that each new layer perfectly aligns with the previous one, and as you might assume, this is central in reprinting efforts.

Accurate registration in multi-layered prints

The most important aspect of producing multi-layered prints is achieving visual harmony. This can only be accomplished through accurate registration, which is why we choose to emphasize this aspect. Accuracy is critical, as misaligned layers may easily result in blurred images or unintended color mixing.

Techniques and tools used for precise alignment

One of the most important things to understand is the relationship between the platen and the printing screen. Creating a grid system is one of the easiest ways to ensure alignment in screen printing.

This system can assure the materials are properly loaded, and the design is properly placed. To align the print, we usually include registration marks in the print. These marks are usually placed at the top and bottom of the center line and on each of the four corners of the print.

Feasibility of Printing Over an Existing Screen Print

Still wondering is it possible to screen print over a screen print? While screen printing over a screen print is possible, understanding the technical aspects and challenges involved is key. Some factors that influence the outcome most are the type of ink, substrate, and design complexity involved in the project.

Ink stains

Mesh stains are one of the common problems that arise in screen designs. Usually, they result from remnants of old ink, but they can also happen due to using too much ink in the print medium.

Hence, the best way to avoid ink stains is regular screen maintenance. A disinfectant cleaner spray can remove stubborn ink portions that could block and minimize ink stains in the final design.

Substrate

As mentioned earlier, precision is one of the most important aspects of layered printing, which is impossible to achieve if your substrate is unstable. This is why, before beginning with the printing process, we always inspect the condition of the palettes to identify if they are stable. After ensuring the palettes are stable, we inspect the adhesiveness that keeps the substrate in place.

Design complexity

Design complexity is another common obstacle in screen printing layering. Simpler designs are generally easier to overlay than complex patterns. When multiple colors and layers are involved in screen printing, the process becomes more time-consuming as each color in the print represents a different layer.

The problem with more complex designs is that screens loosen over time. The constant pressure causes the screen tension to become too low, which directly affects the mesh. This causes the print edges to blur.

Moreover, multi-layer screen printing is labor-intensive, and distraction can easily ruin more complex designs. So, we regularly use a screen tension meter to check the screens before printing to avoid such mishaps.

Steps Involved in Printing Over a Screen Print

At Thrive Screen Printing, we’ve refined the process of printing over an existing screen print into a series of meticulous steps. This method ensures the highest quality results, whether it’s for a local church event or a nationwide marketing campaign for a major brand.

1. Surface cleaning

Cleaning the screen is essential to ensure no residue is blocking the ink. This will ensure the design transfers accurately, and the print appears crisp and clean.

2. Design creation

To transfer a desired design over an existing screen print, first, we have to print the design onto a transparent acetate film. As this is a multi-layer design, we separate the design into different color pieces and create a separate acetate film for each. Then, for each of these, we create a separate stencil.

3. Stencil creation

Once the acetate films are done, each is placed on an emulsion-coated mesh screen and exposed to bright light to develop and harden. The screens are then dried and inspected for any imperfections that might cause a problem in the print design.

4. Aligning screens

Proper alignment is especially important in multi-layer prints. This involves positioning each screen accurately so each color layer aligns perfectly with the others.

Misalignment usually results in blurry, misprinted designs, which we want to avoid when printing over existing screen prints. This is because the final prints might look especially displeasing.

5. Securing registration marks

It’s important to use registration marks to ensure the screen print is properly positioned over the existing print. These markings offer consistent alignment throughout the printing process. Registration marks are crucial in multi-color prints and especially important in more complex designs.

6. Applying ink

The process of applying ink in multi-layer printing is usually more demanding than in standard prints. As mentioned, multi-color designs are complicated, and when reprinting an existing design, you will need to apply each color in the right spot. This requires greater focus and attention. Still, the screen printing process remains the same.

For every color, you have to prepare a different stencil and use the stencils one by one. So, the printing happens by lowering the board and pouring the desired color onto the stencil. Also, we use a squeegee to distribute the ink across the stencil, and ink passes through the open areas.

7. Curing

Curing is an essential part of every screen printing project. This process helps us secure the design in place and ensure greater durability. It can be done using a heat press or a conveyor dryer. The process aims to bond the ink with the fabric, and we achieve this by using heat.

Conveyor dryers are common to industrial production, and these involve running the printed apparel through a heating tunnel. Small-scale businesses prefer using a heat press as they find this machine more convenient. Hence, the curing happens by using a panel to apply heat and pressure over the garment and secure the ink.

Advantages and Limitations

Even though contemporary printing advances have helped us overcome many obstacles, no technique is perfect. Each comes with its unique advantages and limitations.

Advantages of printing over existing layers

Both manufacturers and customers have much to gain from layered printing. Some of its biggest benefits include the following:

Cost-effectiveness

Screen printing over existing designs allows customers and manufacturers to reduce unnecessary textile waste. It offers an opportunity to repurpose garments with a faulty design and make corrections if something goes wrong.

We should emphasize that much good material would probably go to waste if layered screen printing wasn’t an option. Since this method is preferred in large-scale prints, one can imagine the number of garments that will be thrown away.

Enhancing designs

Printing over existing designs is usually done with good reason. Being able to print over a screen print is an amazing benefit as it leaves space for errors that can be undone. Of course, this might not apply to all scenarios, but reprinting is possible for most designs.

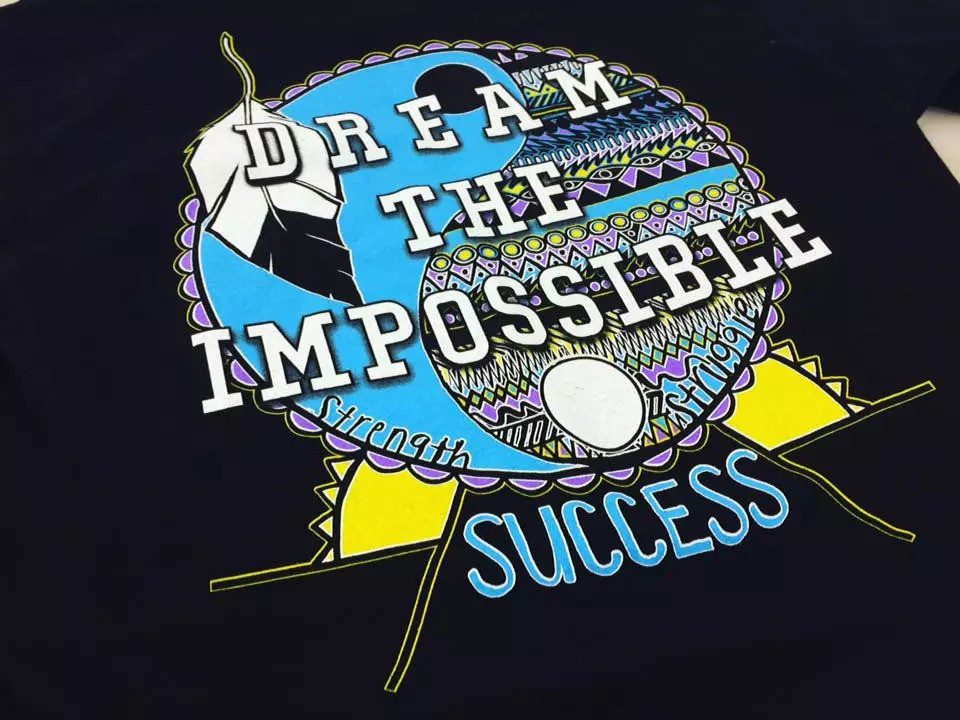

However, layered screen printing is not solely reserved for corrections or when we are displeased by a final print. Multi-layer screen prints are primarily used in the industry to enhance the appeal of the chosen design. This technique allows customers to express creativity through their design and create eye-catching apparel.

Limitations of printing over existing layers

While screen printing over an existing screen print offers a chance to correct printing mistakes, it may also lead to some when done carelessly. One of the possible hazards in layered screen printing is for the colors to blend and result in a displeasing design. This is why taking the time and carefully positioning the registration marks is important to achieve accuracy.

Conclusion

Can you screen print over a screen print? This technique allows us to reprint over existing screen prints and achieve visually stunning results that customers could never identify as a reprint.

Examining multilayer screen printing in detail reveals that every stage, from precise alignment and placing registration marks to ink application and curing, plays a crucial role in the success of the final print.

Undeniably, layered printing comes with some distinct advantages, such as design enhancement and cost-effectiveness. However, it also comes with a risk of design distortion if handled improperly.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.