Silkscreen printing stands out with many unique results in the realm of printing techniques. As industry experts, we dedicated years to exploring and experimenting with this ever-evolving form of printing. So, what is silkscreen printing?

This guide will explore the intricacies of this printing method and offer a step-by-step, detailed explanation of how it works. We will also discuss its benefits and drawbacks to offer a comprehensive overview of its value.

What Is Silkscreen Printing?

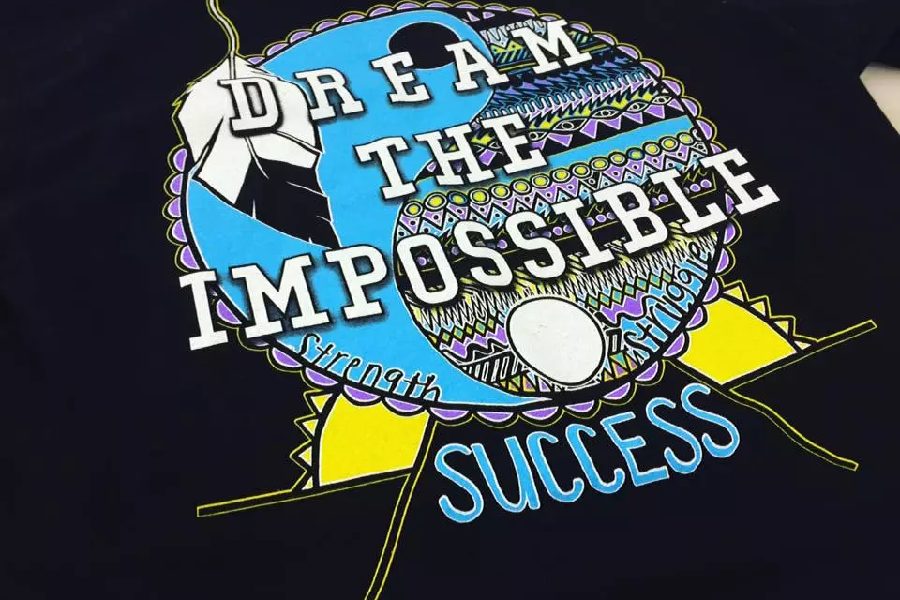

Silkscreen printing, also known as serigraphy, is a traditional method in which ink passes through a stenciled mesh in order to produce a printed design. While this process is much slower and more meticulous than contemporary printing techniques, it offers some of the most elegant results. Its vibrant designs and graphic styles make silkscreen printing popular among customers.

Silkscreen origin

The art of silkscreen printing is believed to originate from 10th century China. The screens used for this printing technique are thought to be originally made from silk, which is how it gets its name. However, this is an outdated practice today, and synthetic fibers have replaced silk.

Silkscreen printing regained its popularity during the early 20th century. During the 1910s, artists began experimenting with this technique using photoreactive chemicals. Later in the 1960s, it became more popularized with the rise of artists such as Andy Warhol, who employed this method in creating pop culture logo brands.

What is silk screen printing best suited for?

Screen printing is best suited for natural fabrics as these can absorb the ink much better than synthetic fibers. Though it can be used in various materials, including microfiber polyester, plastics, wood, and ceramics, challenges can arise.

This is why, generally, silkscreen printing makes a better choice when printing softer materials. Textiles high in cotton bends usually absorb the ink more easily, which is why screen printing is often used in T-shirt and hoodie designs.

One of the most popular questions that arises when silkscreen printing is: can you screen print on silk? The answer is yes, you can. Silk is ideal for screen printing due to its softness and remarkable warmth-to-weight ratio.

However, although the results are stunning, some channels may arise during this process. One of the biggest challenges in screen printing on silk is keeping the fabric in place. These can be difficult in fine silks as the fabric moves around the platen, and preventing this movement is a primary concern, especially in multi-color designs.

How Does Silk Screen Printing Work?

One of the most notable differences between screen printing and other digital printing techniques is that the ink in screen printing sits on top of the fabric rather than being resorbed. This, itself, helps create smoother and more vibrant designs.

At Thrive Screen Printing, we utilize some of the best screen printers for silkscreen printing and within our years of practice and working with clients, we perfected this art. If you are interested in this process, learning more about how to do silk screen printing can help you identify if this method suits your needs.

Design creation

The first step in silk screen printing is creating the design that we want to print on the fabric. This design or pattern is printed on a transparent acetate film, which we later use to create the stencil.

Preparing the screen

We must emphasize that no single-sized solution makes an adequate fit for preparing the screen. We select the screen and mesh count based on the type of material involved. Another major factor that dictates the decision is the complexity of the design.

More complex designs usually feature a greater number of colors. What makes screen printing beautiful is that while using just a single color in bold print designs is preferable, it also allows us to layer colors on top of each other and produce intricate prints.

However, layered screen printing can be complicated as each color must be applied to a separate screen. Once the screen is prepared, it is coated with a light-reactive emulsion.

Emulsion exposure

Next, we pair the film design and mesh screen and place them under a bright light to cause the light-reactive to harden. Any area that doesn’t harden is washed away, leaving us with a ready-to-print design. In the case of layered screen printing, the process gets a bit more complicated as a separate mesh screen is needed for each dye.

Printing

We prepare the stencil once we ensure that the mesh screen is completely dried. We place the desired printing material on the printing place while the screen is carefully placed on top. Once everything is in the proper position, the printing can start.

During this process, the screen is lowered onto the printing board to come into contact with the fabric, and a chosen color is poured onto the screen. The ink is pressed from the screen onto the textile using a squeegee, creating the desired imprint. This process can be repeated as many times as needed.

Quality assurance

When the printing is complete, each item should be dried separately. Special dryers are used for this purpose. Once done, the final product is washed to remove any residue, while the mesh screen is washed to remove any remaining paint that might cause issues in later printing.

Silk Screen Printing Benefits

Silk screen printing is a technique that has endured for hundreds of years and is still widely used in modern printing. The benefits of this technique are the following:

High quality

One of the most prominent qualities of silk screen printing lies in that for this technique we use thicker inks than in other digital printing methods. The use of thicker ink, in turn, results in more vibrant colors that help add boldness to the print.

This technique is also suitable for adding different qualities to the print. It can accommodate specialty inks, such as fluorescent or metallic inks, that complement the visual design.

Customizability

Besides using a variety of inks, screen printing also utilizes a variety of colors. Stencils help create distinct logos and graphics that help cater to the needs of different brands.

Multiple-layer screen printing offers freedom in design. It can be used to achieve different patterns and textures that complement designs by adding more depth to the visual appeal.

Versatility

As we mentioned earlier, silk screen printing is suitable for various materials. But what is silk screen printing best suited for?

It can be used to print brand logos or decorations onto both smooth and textured surfaces. This can be anything from paper boxes to irregularly shaped glass jars. It also works well with textiles and can be used in printing cotton, polyester, silk, wool, and more.

Durability

Another advantage of the thick inks we use in screen printing is their immense durability. These inks help create a dense layer of paint over the textile, which is difficult to scratch or remove.

These prints are also resistant to UV lights and moisture, meaning they will not fade or lose their composure. So, screen printed design will likely last longer than other digital prints.

Silk Screen Printing Drawbacks

When discussing the benefits, we also need to mention the drawbacks. While silk screen printing has many qualities, it’s important to note that it also comes with certain limitations.

Slower production process

While screen printing offers much versatility in ink types and design, the printing process is longer than other digital printing methods. This is mostly because much is done by hand. While sophisticated machinery can streamline screen printing, when a greater number of colors is used, production takes a slower pace.

The reason for this is that each color requires a different stencil. Precision is also paramount, and aligning the stencils can take time. This makes silk screen printing more labor-intensive and time-consuming.

Lower resolution

Screen printing cannot offer accurate details in fine lines and small texts, and compared to other methods, we may say that it has a lower resolution. As we explained, the ink used in this method is thicker and doesn’t make the best option for intricate details.

Conclusion

What is silkscreen printing? Silk screen printing is a fascinating printing technique, ideal for various applications. This technique works well with soft and textured materials and can be used for printing textile fabrics and plastic or wood materials.

It is also compatible with various ink types. However, we must note that in textile printing, we usually use thicker inks. These help create vibrant color and a scratch-resistant layer of ink that resides on top of the material.

Moreover, this technique does come with given limitations. One of its biggest setbacks is that compared to other contemporary printing methods, it requires more time and effort when creating multi-layered designs. Still, we must admit that it is well worth it, as the end results are amazing.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.