Have you ever noticed a peculiar rippling pattern in printed images, seemingly appearing out of nowhere? Chances are, you have encountered the so-called Moiré pattern. But what is Moiré pattern in printing?

In the world of printing, the appearance of such a pattern can be puzzling. As experienced professionals providing printed solutions, we will explain this phenomenon and discuss how to mitigate printing risks to improve print quality.

What Is Moiré Pattern in Printing?

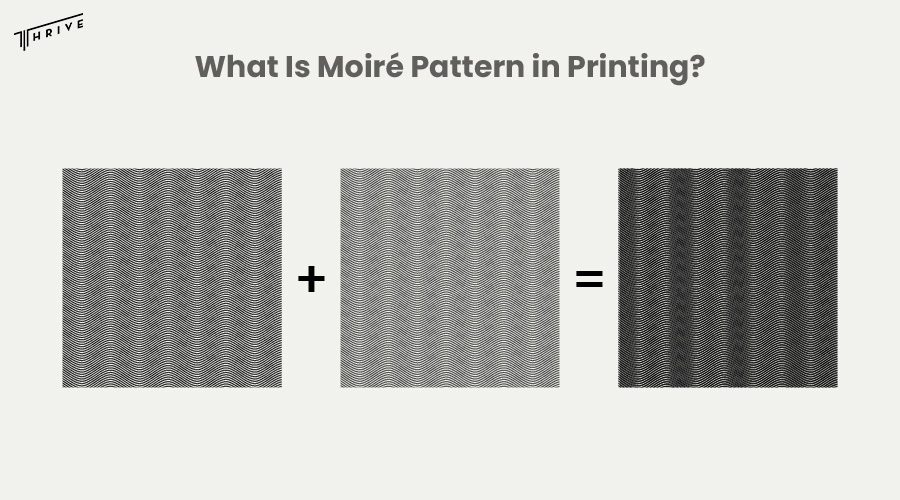

The Moiré pattern, also known as the halftone screen overlay, occurs when two even patterns overlay unevenly. When the two grids of pattern overlap, they create a new printing Moiré pattern with a distinct visual effect.

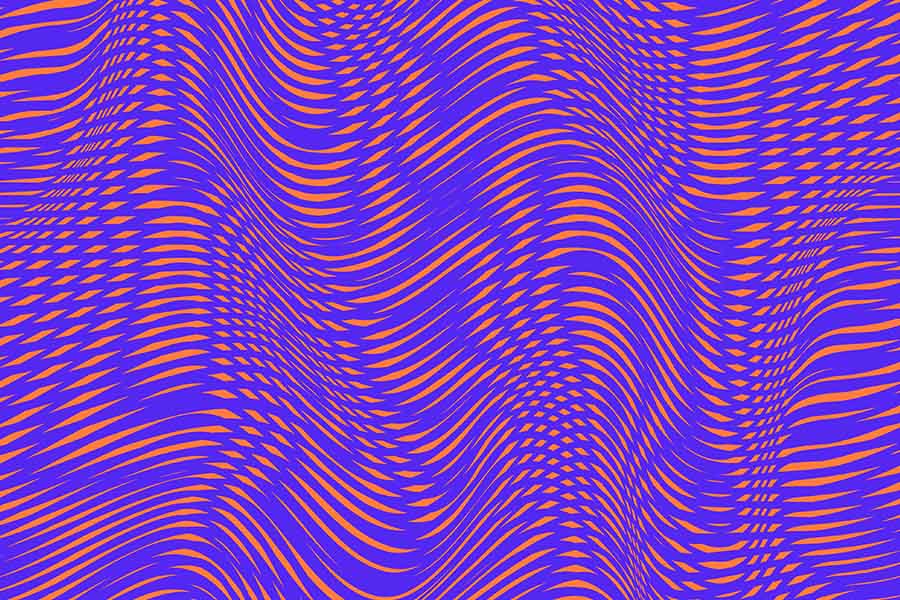

It often manifests as wavy, rippling lines or dots in printing. Such an interference pattern can detract from the clarity and quality of the printed image. You can detect this effect in printing, scanned images, textiles, and display screens.

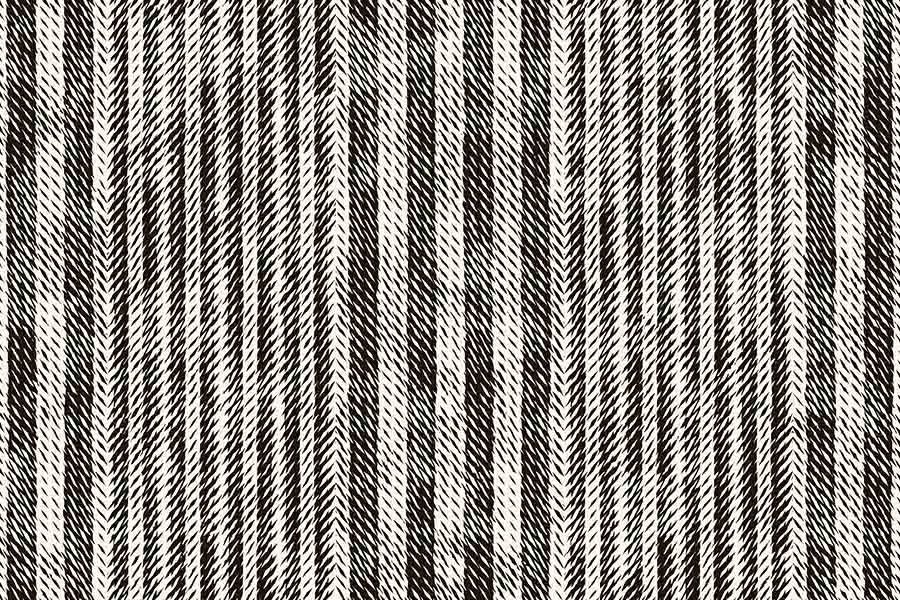

Moiré effect

The Moiré pattern can degrade the quality of the printing material. In graphics, photography, and text, it can obscure details and distort images, undermining the intended impact of the printed piece.

This pattern can also be problematic in high-resolution printing, where even minor imperfections are amplified. Understanding how this pattern appears and how it can affect wholesale screen-printed T-shirts is crucial for ensuring product quality.

Types of Moiré Effect in Printing

In printing, the Moiré effect can manifest in several ways, each influenced by different factors and your printing technique. Here are some of the most common types encountered during the printing process:

Color Moiré

Color Moiré can appear when overlapping layers of different ink colors create interference patterns. This can lead to unexpected color shifts and irregularities in the printed image. It is likely to occur when printing closely spaced or overlapping colors, especially with certain color combinations that can exacerbate the effect.

Line Moiré

Line Moiré generally occurs when two sets of parallel lines or patterns are printed and overlaid at slightly different angles and frequencies. Their interference can create new visually distracting patterns like Moiré grids and waves. This effect often appears in intricate line work like fine text or detailed illustrations.

Texture Moiré

This pattern arises when printing textured or patterned surfaces like textured paper or fabric. The interaction between the printed pattern and the underlying texture can form unexpected visual effects, like Moiré-like patterns or distortions. The texture Moiré is commonly influenced by factors such as the resolution of the printing equipment, the properties of the printing substrate, and the type of ink or toner used.

Geometric Moiré

Geometric Moiré typically arises from the interaction between geometric shapes or patterns in the printed image and the underlying printing grid or substrate. This type of effect can result in the formation of new geometric patterns or distortions not present in the original artwork. Geometric Moiré is especially noticeable in designs with repeating geometric elements or intricate tessellations.

Causes of Moiré Pattern in Printing

Several factors can contribute to the formulation of Moiré patterns in printing. They include:

- Screen ruling – When the frequency of the halftone screen (measured in lines per inch) is too close to the frequency of the pattern you print.

- Incorrect angle – The angle of the halftone dots relative to the underlying pattern can also influence the appearance of such a pattern. If the angles align or are too close to each other, an interference may occur.

- Substrate texture – The texture of the substrate, like paper or fabric, can interact with the printing pattern.

- Digital imaging – In digital printing, a Moiré pattern can arise due to the interaction between the resolution of the digital file and the halftone screen frequency.

How to Avoid Moiré Pattern in Screen Printing

If you are screen printing, avoiding the Moiré pattern requires attention to detail and consideration of multiple factors. We presented several strategies to minimize or prevent their occurrence.

Prepare the mesh

Choose a quality mesh screen with the appropriate mesh count for the desired level of detail in your print. Ensure that your printing screen is tensioned correctly. Check whether it is free from defects and inconsistencies that can create such a pattern.

Align the screen

Accurate screen alignment is crucial for preventing the Moiré pattern. This is because it is often caused by interference between the dot patterns of the screen and the printing substrate. We recommend using registration marks or alignment tools to ensure precise registration between colors.

Halftone settings

To minimize the likelihood of the Moiré pattern, fine-tune halftone settings such as dot size, shape, and angle. Experiment with different settings until you find the optimal configuration for your substrate and specific printing job.

Implement color separation technique

Make sure to implement effective color separation techniques to prevent the formation of this effect due to color interference. Adjust the ink density, the screen angle, and the color combinations to minimize the risk of overlapping colors and unwanted visual artifacts.

Choose substrate

Another way to minimize the risk of the Moiré pattern is to choose printing substrates with a smooth and consistent texture. Avoid textured or patterned materials that could interact unfavorably with the printing screens and inks.

Control ink application

Control ink deposition and flow during the printing process to ensure uniform coverage. It is essential to minimize ink buildup, as it can contribute to Moiré patterns. Use proper squeegee pressure and flood stroke techniques, and make suitable ink viscosity adjustments to achieve optimal results.

Conclusion

What is Moiré pattern in printing? You can create visually appealing prints by knowing it and implementing appropriate preventative measures.

With a meticulous approach to screen printing, it is possible to minimize the occurrence of Moiré patterns and achieve high-quality, visually appealing prints. As printing technology advances, addressing such patterns remains essential for achieving optimal print results.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.