Have you ever wondered how a spectrum of colors fascinatingly translates into vibrant and exquisite prints? The answer lies in an artistic process for creating colorful creations known as color separation. But what is color separation in printing?

This fascinating technique is essential for reproducing full-color images accurately. It ensures the final print reflects the intended colors and details of the original artwork. Let’s discuss how it works and unveil its significance in the printed industry.

What Is Color Separation in Printing?

Color separation is fundamental in the realm of printing, bringing designs to life with stunningly vibrant colors. You can use this technique for everything from T-shirts to posters and fine art and produce vibrant and complex designs with high precision.

Imagine an enchanting image in multiple colors – a photo of a sunset on the beach with fiery oranges, deep blues, and streaks of pink tones. To recreate the artwork into a T-shirt, you can’t just slap the colors onto the fabric at once.

Since screen printing works by forcing ink through a mesh stencil and into a substrate, each color needs its separate stencil. With this in mind, you must ensure the colors that make the design are separated for reproduction on a printing press.

This is where color separation takes place. This technique involves breaking down a full-colored image into individual color components that you can print separately. It separates the colors of the digital file in order to prepare it for printing.

Understanding the essence of color separation

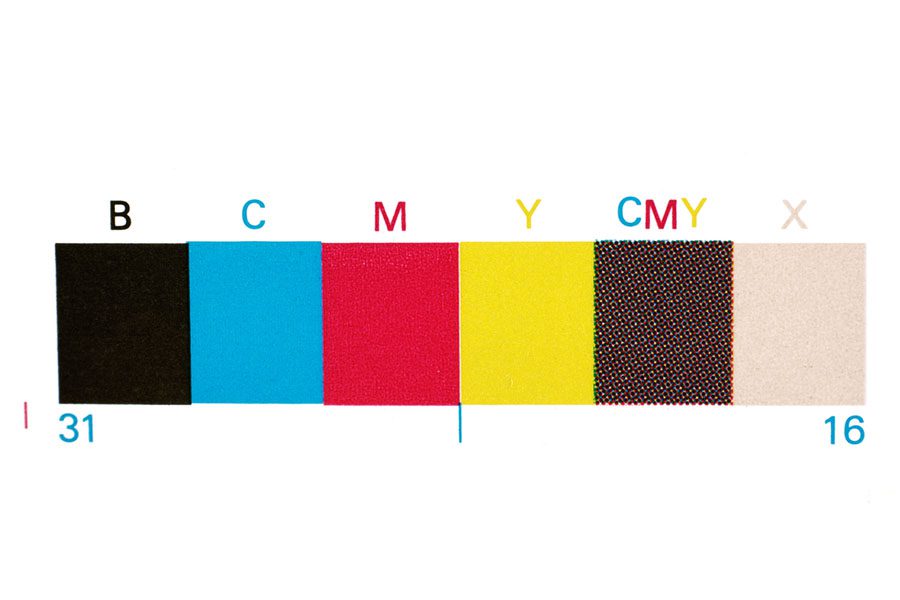

The primary purpose of the color separation process is to prepare the file for printing and ensure vibrant color reproduction. The elements of the file are printed in colors like cyan, magenta, yellow, and key (black), commonly known as the CMYK color model, which can create a broad range of hues and tones.

Hence, color separation is an essential part of screen printing as it provides you with separate pictures for every color in the design. So, how to do color separation for screen printing? Mastering this technique can help you achieve stunning results.

As leading printers with years of experience in screen printing, we will provide more details on the color separation process in the section below. If you are on the hunt for the best contract screen printing, you can contact us today!

What Is the Color Separation Process in Printing Necessary For?

Color separation is the backbone of screen printing that enables you to create multicolor magic. With this technique, you can produce complex designs with multiple colors. As a matter of fact, you can achieve a broad range of colors and effects by combining different hues and opacities.

By printing colors one at a time, each layer sits on top of the previous one, creating a rich and vibrant final print. Separating the colors prevents any unwanted color mixing that can blur details in the design. It ensures each ink covers only the intended area, achieving sharp details and optimizing the printing process.

Types of color separation

There are different types of color-separation printing techniques. The method of color separation you should choose depends on the complexity of your design, the surface you will print on, and the desired outcome you would like to achieve.

That said, understanding how they work and the challenges that come with them is crucial for printing. Typically, software like Photoshop, Illustrator, and CorelDRAW can help you take care of this task effectively.

Spot color separation

Spot color separation is the most common method that you can use on vector images, logos, cartoon graphics, etc. It allows precise color management and may involve halftime dots to create a shading effect.

Four-color process

This type of color separation technology involves the use of CMYK color mode. In fact, most of the colors in the image can be created by printing these tones. The process includes small or halftone dots for creating photorealistic images.

Simulated color separations

The simulated color separation also utilizes halftones to create images. It can handle a range of ink colors, which is essential for creating vivid and photorealistic images. You can use the simulated process for both light and dark backgrounds.

Index color separations

Square pixels of the same size are utilized for color shading in index color separations. These squares are used for color shading with a specific and restricted selection of colors, typically the most prominent colors in the image. The designers may use software to create images that look as close to the original as possible.

Conclusion

When it comes to printing, the color separation process plays a crucial role in achieving quality and stunning prints. What is color separation in printing? This technique translates vibrant digital creations into tangible, colorful prints. It is a fundamental piece of the printing puzzle, allowing us to achieve a vast array of colors on the printed page and bring creative visuals into reality.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.