When choosing color models for your next project, you may come across two renowned names that stand out in the printing industry – spot color and CMYK. Many organizations may have trouble deciding which best suits their needs, as both methods offer unique advantages and limitations. However, by understanding and weighing the distinctive factors that differentiate spot color vs CMYK, you can make an informed decision and select the ideal model for the next projects, considering color accuracy requirements, design complexity, and budget.

So, what is the difference between the two printing models, and why are they so popular within our field? In this article, we’ll elaborate on the key differences between spot color and CMYK, discussing their distinctive characteristics in color accuracy and options, how each method handles complex designs and their cost-efficiency.

Understanding Spot Color

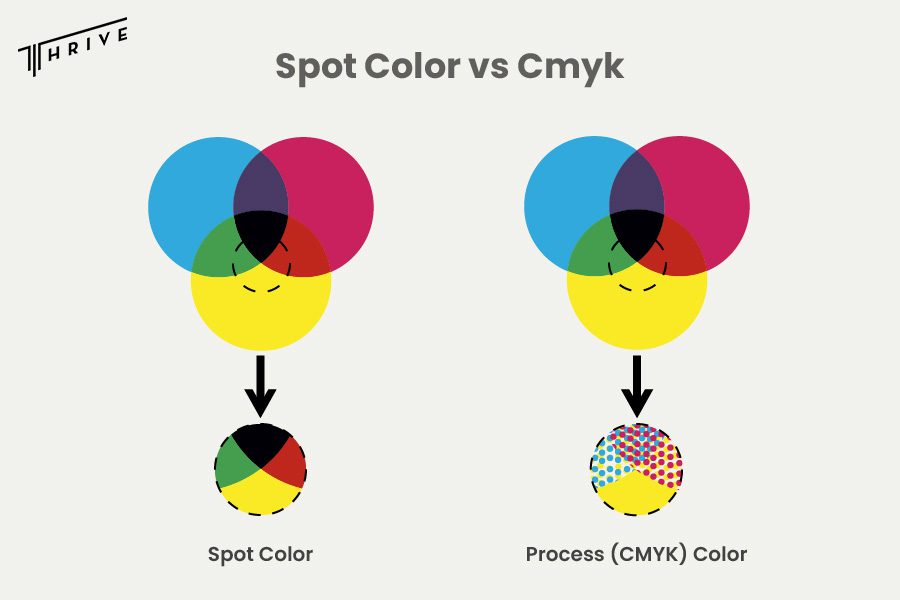

Spot color is a renowned technique in the printing industry used for the reproduction of specific colors in printed materials. It involves using standalone pure or premixed solid inks to achieve a single hue and shade with precision and consistency. A unique code identifies each color for a standardized color-matching system known as the Pantone Matching System (PMS), which ensures consistent color reproduction across different printing methods and materials.

This technique is commonly used in printing projects that require impactful designs with unusual color spectrums, enhancing the visual appeal and maintaining a captivating allure. It can also boost the image’s vibrancy, providing a vivid and saturated color scheme that commands attention and leaves lasting impressions. Due to these characteristics, spot colors are most commonly used in branding materials, packaging, and promotional items, where brand identity and consistency are critical.

With our expertise and nuanced knowledge, you can leverage the power of the best wholesale screen printing for shirts and gain a positive impact on your brand!

Understanding CMYK

The CMYK color model is the common abbreviation for four-color process printing using Cyan, Magenta, Yellow, and Key (black). In this type of printing, colors are created by overlapping transparent ink layers of the four colors, creating an infinite number of shades and hues. It strongly relies on halftoning, a technique that simulates continuous tones by diverse sizes and spacing of tiny dots, creating a similar result to the pixels on a digital image.

The printing process begins with a white background, usually paper or the substrate, onto which the four ink colors are applied in varying combinations and densities, producing the desired colors in the design. Cyan absorbs red light, magenta absorbs green light, and yellow is the corresponding filter absorbing blue light, while key or black enhances contrast, creating a deeper shade. More ink on the substrates means less light that reflects CMYK inks.

CMYK is the industry standard for various printing mediums, such as branding materials, brochures, documents, and packaging.

Key Differences: Spot Color vs CMYK

Color accuracy

Spot color and CMYK are widely recognized for their distinct color accuracy capabilities and consistency in hues. For spot color, we may say that it often outperforms the CMYK printing model, offering vibrant and long-lasting results on various materials. Due to its process, it can deliver precise ink formulation and color reproduction, allowing an exact shade replication across diverse print runs and substrates. It’s particularly advantageous for projects requiring exact brand colors across various materials for consistency in brand identity.

On the other hand, CMYK offers a broad range of colors, including cyan, magenta, yellow, and key, resulting in variations in color accuracy. However, it may struggle to precisely reproduce certain hues and achieve specific color matches, especially with extremely vibrant or specialty shades. This can be a result of numerous factors, including ink saturation, printing medium texture, or printing conditions. Nonetheless, CMYK still remains a viable option for accuracy and precision.

Color options

Although spot coloring provides more precise color accuracy, CMYK significantly surpasses spot color models when comparing the availability of color options, providing a broader spectrum of shades by layering transparent cyan, magenta, yellow, and key in varying combinations and densities. In fact, over 50% of spot shades and hues are outside the color spectrum range of CMYK.

Although spot coloring may be more limited, it provides more precise and accurate color options when compared to CMYK. Additionally, CMYK may encounter issues when reproducing specialty colors like metallic or neon shades, requiring additional spot color inks to reach the desired outcomes. Despite these limitations, both methods offer versatility and a wide range of color options for diverse types of projects.

Design complexity

The design complexity of CMYK vs spot color screen printing can significantly impact the final outcome of the print as both methods have distinctive characteristics suitable for unique projects. CMYK is an extremely versatile and flexible technique, excelling in handling complex and intricate designs with exceptional gradients and detailed imagery. Due to its capabilities in color variations and precision, it’s often used to print almost exact replicas of full-colored images and realistic photographs.

On the other hand, spot color is well-suited for designs with specific color requirements or branding guidelines, allowing color accuracy and matching. However, this method may experience some challenges when dealing with complex designs or intricate color gradients.

Cost-effectiveness

So, are spot colors the same as CMYK in affordability?

While spot color printing requires a singular ink color for each spot color used, CMYK printing utilizes four inks to create various spectrums. Therefore, with CMYK’s ability to reproduce a wider range of shades and hues, it’s generally more affordable for projects requiring multiple colors. In contrast, for jobs requiring only one or two colors, spot color printing can be more cost-effective when compared to CMYK.

Choosing the Right Method

Contemplating between spot color and CMYK color models often requires considering several factors regarding personal preferences and company resources. This includes considering:

- Budget constraints – assess the cost-effectiveness of using spot color or CMYK, ensuring the chosen method fits within your budget.

- Project requirements – make sure you evaluate your project’s specifications and needs, as it will allow you to make a more informed decision on which model best suits your demands. This can include anything from the number of colors required and the desired print method to the intended output.

- Importance of color accuracy – if color accuracy and consistency are crucial for your project, then spot color may be a preferred option.

Ultimately, the choice between spot color vs CMYK lies in your unique design needs and preferences.

Conclusion

So, what is the difference between spot color and CMYK printing?

In conclusion, both spot color vs CMYK offer distinctive advantages and limitations, each impacting the final outcome of the printing projects. By understanding and evaluating their differences and aligning them with your project demands, requirements, budget, and personal preferences, you can make an informed decision, ensuring a successful and satisfactory outcome.

We hope this article has provided you with valuable insights into the key differences between spot color and CMYK. With our expertise and nuanced knowledge, we aim to create a tailored approach for your project, optimizing both quality and cost-effectiveness and ensuring your project meets your unique objectives effectively.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.