Custom apparel has become a crucial part of marketing strategy for many organizations because it creatively represents their objectives. Keep reading to find a detailed comparison between screen printing vs digital printing and decide which method is better for your business.

Digital printing was considered a new technique in the custom apparel industry. However, recently, it has become a rival to traditional screen printing. These two printing methods differ in quality, affordability, and versatility. But they are both equally used by many people.

In this article, we point out the difference between screen printing and digital printing to help you choose what technique you need based on the requirements of your organization. In addition, we offer reliable services for customizing apparel and creating unique designs.

Screen Printing vs Digital Printing

Before learning the dissimilarities between screen printing vs. digital printing, we must explore their separate purposes in the custom apparel industry.

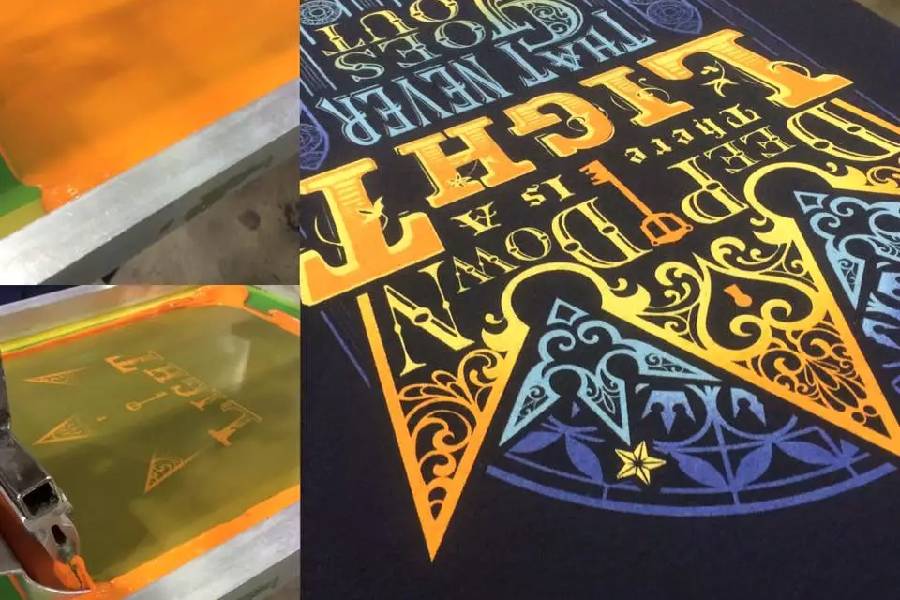

With professional screen printing, our team creates a stencil to apply ink on a product surface. Then, we apply the ink colors using different stencils to make the project look cohesive. This way, we create the desired final look per the client’s request.

We consider screen printing great for vibrant designs on dark printing surfaces like dark-color T-shirts. The screen printing ink is thick and produces bright colors even when applied on black surfaces. In addition to apparel, we can also screen print your desired design on mugs, pens, and water bottles.

In contrast, digital printing is a modern technique involving design processing with a computer. Then, the design is printed directly on the surface of the product. It’s a great option for detail-oriented projects because the ink is extremely thin.

Now that we’ve covered the basics of screen and digital printing, let’s look at their differences in great detail to decide which one is better.

Technology and equipment

Technological advancements in digital and screen printing industries have improved final projects’ accuracy and efficiency. Digital printing is a more innovative technique but can’t fully replace screen printing quality.

Automatic screen printers can easily produce a large quantity of garments, up to 100 pieces per hour. This type of equipment allows us to produce high-volume orders. It also enables us to offer the highest quality projects to our clients.

Digital printing requires the use of professional machines to produce high-quality prints that many businesses find costly. However, to minimize costs, we can take low-quantity digital printing orders and rely on screen printing for high quantities.

Usage

When comparing screen printing vs. digital printing, it’s important to identify their specific purposes and determine when one should be used over the other.

Screen printing is a better technique for large and high-volume orders. It is great for creating colorful or single-color prints, text, and logos. This method is also perfect for printing on polyester and other synthetic fabrics. It also helps us achieve exact color matching.

On the other hand, digital printing is better for smaller, simple orders. It is suitable for printing on 100% cotton materials and creating detailed designs. Also, it’s an ideal printing method for implementing photographic elements with colorful designs in various projects.

Color saturation

Many of our clients request their projects to have vibrant colors, good saturation, and enough brightness. Throughout our experience, we discovered that digital printing offers a duller color saturation compared to the vibrancy of screen printing.

This difference comes from the use of plastisol ink in screen printing. This type of ink contains PVC particles that are very opaque and look bright even when applied on dark printing surfaces, highlighting their fluorescent appearance.

For digital printing, we use water-based inks. These types of inks lack the vibrancy of plastisol inks and don’t create bright results.

Durability

The durability of prints has a lot to do with their quality. Digital printing has struggled with durability since the beginning; the garments would barely last up to 10 washes. Thanks to the new technological advancements, digital prints can last longer today.

Screen printing produces more durable projects if the ink is applied and cured properly. Although plastisol ink is durable, it can fade or deteriorate if not used accurately. High-quality screen prints can last for many years without any visible damage.

Versatility

We consider certain printing techniques more versatile than others. For example, the ink used in screen printing is very flexible and perfect for different garment fabrics and print locations.

In contrast, digital printing has some limitations because it doesn’t work on all fabrics. The safest choice with digital printing is 100% cotton because blended fabrics and polyester are not recommended, especially if they are colorful. In these cases, the colors may bleed out and discolor the print due to the moisture-wicking characteristics of the materials.

Consistency

Our clients often order large quantities of T-shirts and want each piece to look identical. In such cases, to achieve consistency in our projects, we use the digital printing method. This is due to the machines’ ability to print the designs directly and precisely on the designated area of the garments.

Screen printing can also be consistent, but only if done properly. This technique has many variables, like screen tension, sharpness, pressure, and angle. These factors may lead to slightly different designs on each garment.

Detail precision

If our clients request their project to highlight every tiny detail in the design, we turn to digital printing instead of screen printing. Digital printing can emphasize every small detail, including fine lines, text, and other similar elements.

Details are more difficult to accentuate with screen printing. But we can make this technique work for certain projects by slightly adjusting their design, like increasing the text size, to create high-quality and detail-focused screen prints.

Both screen and digital printing require the use of halftones or tiny dots for photographic images that can be visible when looking at the project up close. Due to this, both printing methods may result in a grainy look. But digital printing captures small details better.

Cost comparison

The cost of screen and digital prints depends on the quantity clients require and the equipment used during project creation.

The initial screen printing setup will work out in the long run if businesses get numerous daily orders. Once a screen printer is calibrated, you won’t have to do it again or pay additional fees. For smaller quantities, digital printers are the best alternative.

The printing price may also depend on the number of colors we use in our projects. Simple black-and-white projects are cheaper than colorful ones.

Screen Printing vs Digital Printing: Which Is Better?

Deciding which printing method is best can be tricky because they both have advantages and disadvantages. The choice between screen printing vs digital printing usually depends on what designs clients intend to print and the printing surface.

Digital prints are more precise, crisp, and detailed. But screen prints are unique, softer, and offer a retro look. Both printing techniques are good and serve different purposes. But there are some things to consider before making a final decision.

Digital printing is suitable for smaller quantities of prints, while screen printing is a perfect choice for high-volume orders. In addition to having more versatility, screen printing is also more durable than digital printing.

However, you must remember that digital prints work better for projects with hyper-detailed designs. By using this technique, the final prints are higher in quality due to its ability to achieve consistent color reproduction.

The initial cost for digital printing equipment is lower than screen printing, but you must decide what method will benefit your business long-term.

Conclusion

We hope our guide has given you a clear understanding of the contrast between screen printing vs digital printing and how these two methods can benefit different businesses.

Typically, the organization has the last word. Our clients base their choice on the number of items they need, their preferred designs, and garment printing requirements. You can rely on our team of professionals and printing experts to get advice on the printing method that best fits the needs of your particular organization.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.