Screen printing is a complex technique. We have used it for years in our company to make printed products and faced many challenges to get perfect results. But what are the most common screen printing problems and solutions?

We might encounter many situations when screen printing for your business. Yet, as a customer, you don’t have to worry about them because you will get a product with high print quality.

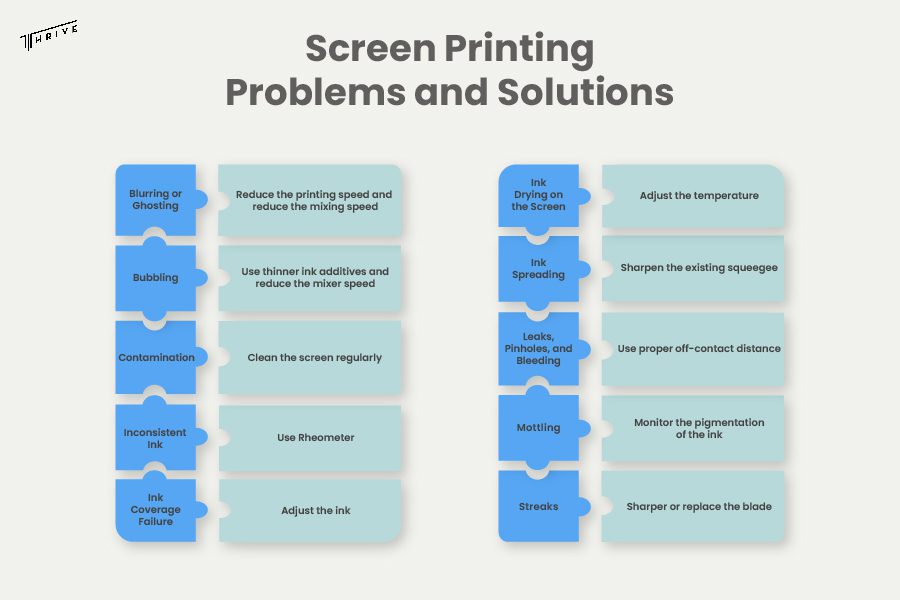

Let us reveal the most frequently occurring screen printing defects we must fix during production.

Screen Printing Problems and Solutions You Should Know About

Many of our clients choose to print their products by using our screen printing services because they offer many benefits. Screen printing is known for its versatility, durability, vibrant colors, cost-effectiveness, and fast turnaround times.

However, we need to manage multiple screen printing challenges and find ways how to fix screen printing mistakes. So, what are common problems that can occur during screen printing? As an experienced and high-grade contract screen printer, we encounter the following issues:

- Blurring or ghosting

- Bubbling

- Contamination

- Inconsistent ink

- Ink coverage failure

- Ink drying on the screen

- Ink spreading

- Leaks, pinholes, and bleeding

- Mottling

- Streaks

1. Blurring or ghosting

One of the first screen printing problems and solutions we will cover is blurred or ghosted images. Sometimes, the edges of the print come out blurry, wavy, or smudged.

In our experience, there are several causes of getting a blurred or distorted image. The most common reasons the color of the garment fades or disappears in screen printing are:

- An ink mixed at high speeds makes bubbles

- Fast printing speeds

- Static causes press sheet sticks to mesh

- The substrate is not fixed during printing, causing it to move

- Underexposed emulsion

- Screen with low-tension stretches

Depending on the cause of the issue, we can utilize multiple solutions to this problem. For instance, if we determine that the press sheet sticks to the mesh, we will continue reducing the printing speed. Then, we increase the vacuum to create a tight positive contact. Also, our team might adjust the snap-off.

On the other hand, if we see that the ink has bubbles, we have two options. The first one is to give the bubbles time to disperse. The second solution is for us to reduce the mixing speed so that we can avoid blurry or distorted prints in the future.

Another solution we use from time to time is adjusting the offcontact. Typically, we change it to be as thick as a nickel.

2. Bubbling

The appearance of air bubbles is also problematic when using the screen printing technique. These screen printing defects have two main causes for bubbling in screen printing. The problem can be either the ink or the high printing speed.

Regarding the ink, there are a few scenarios that may cause bubbling. First, bubbles can appear on the print if the screen printing machine deposits too much ink. We solve these printing issues by transferring less ink to the substrate. To do that, we start using a harder squeegee.

Furthermore, bubbling can happen if the ink is too thick or the previous one gets bubbles from the fast mixing. If we see that the root of the bubbling is connected with the ink, we use one of the following solutions:

- Using thinner ink additives

- Disperse the bubbles in the ink by reducing the mixer speed

Other causes of air bubbles in screen printing might be a wrong proportion of defoamer and using easily foamable transparent inks like green, blue, and red.

3. Contamination

Sometimes, there are areas on the prints where certain sections of the image lack ink. Some hints of a printing issue are lint or dust in the image area and contaminated substrate. Hence, we eliminate the chances of contamination by regularly cleaning the screen and our working area.

4. Inconsistent ink

Some prints may have inconsistent ink. Luckily, our quality control team always notices when the ink viscosity is off. So, we will utilize several techniques to ensure the prints continue with the desired consistency.

We can use a rheometer to check the consistency of the ink. If it needs to be thinned out, we might add additives. We also don’t want the ink to be too thick because it will lead to various other issues, such as not going through the mesh, clogging, and resulting in uneven prints.

5. Ink coverage failure

There are many designs where we need to add multiple layers of color. In such situations, it is common for us to deal with what we like to call second-color refusal. In other words, that is when the second color doesn’t cover the first one.

The reason for ink coverage failure is the ink itself. It may appear if the ink contains too much silicone, is too thick, or has a solvent release. The solution to this problem is adjusting the ink.

6. Ink drying on the screen

When it comes to ink drying on screen, there are three reasons. Consequently, according to the cause, we can implement three solutions.

For instance, if the ink is too thick and dries, we will first wash out the stencil and continue by inspecting the ink. If there is a need, we will make it thinner by adding solvent.

Other times, the ink might be drying on the screen because of the high ambient temperature. Besides adjusting the temperature, we can add a print retarder to the screen printing ink to slow the drying process.

7. Ink spreading

Next on our list of screen printing problems and solutions is ink spreading. Many signs indicate that there has been ink spreading and show us that we need to take proper action if we notice that the image is thicker than the desired and unsharp edges.

If the reason for spreading is that the ink is too thin, we might use a harder ink additive. But ink spreading might also happen if the squeegee is rounded. To avoid the ink from spreading further, we sharpen the existing squeegee or replace it with a new one.

8. Leaks, pinholes, and bleeds

Leaks, pinholes, and bleeds are the most common screen printing problems. Since we are focused on providing our clients with high-quality prints, we immediately act when we see ink in an area outside of the design. To fix leaks, pinholes, and bleeds need to remake the stencil and take other measures such as:

- The amount of ink we use.

- Using proper off-contact distance.

- Maintaining the mesh screen properly, especially by cleaning it.

- We check that the screen is appropriately stretched.

Finally, we use adequate ink according to the substrate on which we print.

9. Mottling

Mottling is a situation when the ink is not absorbed equally by the substrate. We may face this challenge if we use insufficient ink film, thin ink, or poor stock.

However, the good news is that we rarely get this problem. To achieve that, we monitor the pigmentation of the ink, change the stock when needed, and use coaster mesh.

10. Streaks

What are common problems faced in screen printing caused by squeegees that are not sharp enough or damaged flood bars? Well, one of them is streaks. You can notice them as faint lines appearing on the printed image.

We don’t usually have to deal with streaks because we always do a quality check on our equipment. Yet, it frequently happens to other screen printing companies. This screen printing defect can be easily avoided by sharpening or replacing the blade or the flood bar.

What Are Some Common Solutions for Achieving Crisp and Clear Screen Prints?

Before we wrap up, we will reveal some of our secrets for creating clean and crisp screen prints:

- Checking our screen printing machine before every run and doing a test print.

- Using proper mesh count screens according to the ink type we are using.

- Picking the right screens and their tension.

- Calculate the best squeegee angle and pressure.

- Curing the ink properly.

Conclusion

Knowing the screen printing problems and solutions will help you better understand the process we go through to make your product. If you decide to give us your trust to print the garment for your business, you won’t have to worry about seeing any of the mentioned screen printing defects. Our screen printing and quality control team will ensure you get high-quality prints!

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.