The printing industry employs many printing methods like screen, offset digital, and more. This makes it difficult to understand them and decide which technique suits your needs best. However, two methods stand out and emerge as the most popular. Comparing DTG printing vs sublimation can help you choose the most sustainable approach for your project and achieve your desired results.

Whether you’re embarking on a small or large-scale production gig, you’ll need to consider several factors when contemplating between DTG and sublimation. That’s why we’ll provide a comprehensive guide explaining each aspect of these methods, including quality, complexity, vibrancy, and much more.

By exploring the advantages and limitations of each technique, you can confidently make informed decisions and select the right option for your next project. Let’s start!

The Basics of DTG Printing

DTG printing, also referred to as direct-to-garment printing, is a relatively modern method of apparel decoration that harnesses the power of advanced technology. It involves applying ink directly onto a desired fabric, producing high-quality resolution and full-color reproduction designs.

The process begins by preparing the digital design on a computer and adjusting it as necessary, which is transferred directly onto the fabric through a printer. Then, a pretreatment is applied to the garment to ensure proper ink absorption.

Once the product is loaded, the DTG printer utilizes water-based inks and sprays them onto the fabric, resulting in vibrant and detailed prints. The finalized product is then put in a heat press to solidify the ink and make it permanent.

Unlike traditional printing methods such as screen prints, contract DTG printing services excel at producing intricate designs with unparalleled precision while delivering a soft finish. It’s one of the most recognized on-demand printing methods in the industry.

The Basics of Sublimation Printing

Sublimation printing is an alternative to screen printing that uses advanced technology and specialized inks. It may provide one of the most durable, permanent, and vivid prints. The method relies on manual operation rather than digital, embedding the design in the fabric fibers using ink and heat transfer with pressure.

The process begins by printing the design onto a special sublimation paper using specialized inks. Next, the paper is placed onto the fabric, and pressure and heat are applied to the item using a heat press. The heat and pressure convert the specialized inks into gas, transferring them onto the fabric. This creates unparalleled absorption levels, resulting in permanent, exceedingly vibrant printed designs.

Sublimation is particularly favored for its ability to produce high-quality designs and full-color gradients that may be challenging for other printing methods. We consider it one of the most efficient methods for achieving long-lasting prints.

Comparing DTG Printing vs Sublimation

1. Quality and precision

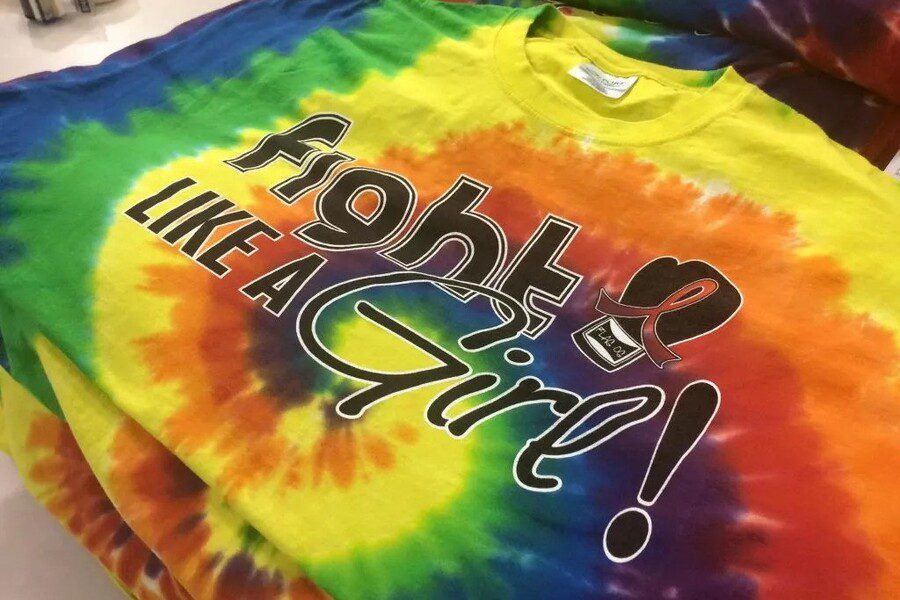

DTG and sublimation printing are widely recognized for their distinct printing capabilities and characteristics. For sublimation, we may say it offers an astonishing quality of vibrant and long-lasting prints with exceptional detail and precision. Its process allows seamless integration of complex, full-color designs onto polyester fabrics, delivering photo-realistic results and extraordinary gradients.

On the other hand, DTG also offers exceptional printing quality and precision of intricate designs on various substrates with precision. This method’s advantages lie in its ability to seamlessly refine details and execute complex, multicolored designs. However, sublimation prints tend to be more durable than DTG in terms of durability.

2. Print complexity

Sublimation is quite a versatile technique, excelling in handling complex, intricate, and vibrant prints with exceptional gradients and detailed imagery. This method involves transferring specialized ink from sublimation paper through a gas state, requiring special equipment, temperature control, and a specially coated printing surface.

Nonetheless, DTG offers detailed and intricate designs with minimal setup and complexity, printing directly onto the substrate. This method demands careful consideration of garment type and pretreatment coatings to ensure vivid final results.

3. Color vibrancy

Is DTG the same as sublimation when it comes to color vibrancy? Both sublimation and DTG printing offer exceeding capabilities and accuracy in color reproduction. These two prominent methods utilize the same CMYK color model, meaning they use four primary colors to print all designs: cyan, magenta, yellow, and black.

So, when vibrant color is necessary, sublimation produces vivid hues by transferring specialized ink onto fabric through a gas state, bonding the ink with the fabric. It results in impressive durability. In contrast, when accurate hues are needed, DTG offers impressive color reproduction directly onto fabric using inkjet technology.

4. Production time

We can say both methods have varying characteristics when comparing the production times and on-demand capabilities between DTG printing vs sublimation T-shirts. Regarding production time, on-demand fulfillment, and speed capabilities, DTG printing takes the lead as its turnaround time is significantly faster than sublimation.

Hence, since the method allows direct printing onto fabric, it eliminates the need for setups and additional steps. Whereas, sublimation requires a multi-step process of preparation and transfer, resulting in longer and more time-consuming production times.

5. Eco-friendliness

Generally, sublimation printing emerges as a more environmentally conscious and eco-friendly alternative for a printing project. The process employs specialized inks that don’t contain harsh chemicals or toxins that could harm the environment.

It also doesn’t require much water during printing, contributing to water wastage and minimal energy consumption. Moreover, sublimation typically uses polyester fabrics, which can be recycled, further enhancing its eco-friendly profile.

Conversely, DTG printing is also a great option when considering eco-friendliness. This method utilizes water-based inks, which are generally more environmentally conscious than solvent-based inks. Additionally, DTG possesses precise and accurate applications, making it well-suited for printing one-offs and allowing you to avoid overproduction and fabric wastage.

6. Cost considerations

Comparing the costs between DTG and sublimation printing demands considering several factors. The first one is the quantity of your project.

Typically, sublimation is considered to be much more cost-effective for large orders. The cost of sublimation equipment like specialized inks, heat presses, and transfer papers can contribute to the overall price.

Although the method often involves higher upfront investment due to its initial requirements and specialized apparatus, the cost per unit decreases as the setup is in place. This makes sublimation printing a preferred and economical choice for large-scale quantity projects.

On the other hand, DTG is usually preferred for smaller quantities. While this printing method eliminates the cost of setups, DTG printers are often more expensive.

The process also requires some extras like pretreatment solutions, maintenance supplies, and curing equipment to ensure a high-quality result. Ultimately, the cost per unit in DTG can be higher than sublimation as the quantity increases.

Conclusion

DTG and sublimation are valuable methods of apparel decoration in our company, offering distinctive advantages and limitations. While DTG excels in producing intricate, vibrant, and complex designs, sublimation stands out for its unparalleled durability in prints and cost-effectiveness in large-scale productions.

Whether you’re a small or large business looking for a suitable printing method for your next project, comparing and distinguishing each characteristic between DTG printing vs sublimation is paramount. By carefully evaluating the key differences like quality, complexity, color vibrancy, production time, and cost considerations, you can make informed decisions that align with your needs.

Hopefully, our guide has helped you understand the basics of DTG and sublimation printing, empowering you to make the right choice.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.