If you’re seeking to elevate your custom apparel with eye-catching, three-dimensional effects that customers can’t resist touching, you’ve found the definitive resource. We understand that navigating specialty printing techniques can be overwhelming, but rest assured—this comprehensive guide will demystify dimensional puff printing and show you exactly how to leverage this tactile technology for your brand.

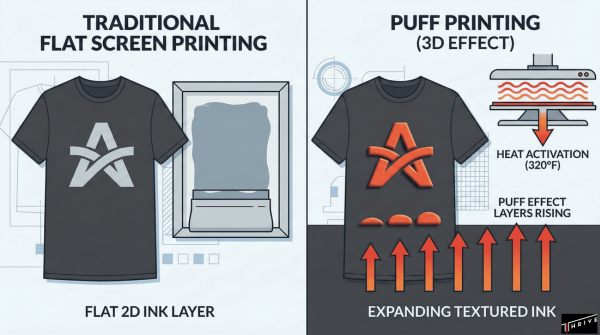

Dimensional puff printing is a specialized screen printing technique that transforms flat designs into raised, three-dimensional surfaces through heat-activated plastisol inks containing foaming agents that expand at 320°F (160°C). Unlike traditional screen printing methods that produce flat images, puff printing creates tactile artwork that expands both vertically and horizontally during the curing process, resulting in soft, pillowy textures that engage multiple senses and command premium pricing in today’s texture-focused apparel market.

TL;DR Summary:

• Puff printing differs from traditional techniques by using heat-activated foaming agents in plastisol ink, lower mesh counts (80-110), and thicker emulsion layers to create 3D effects that standard printing cannot achieve

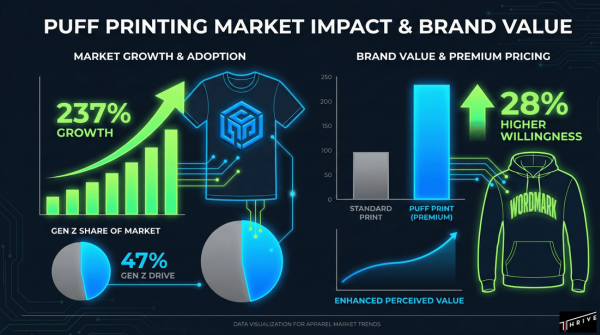

• The technique offers significant market advantages with 73% of young consumers prioritizing texture, 89% more likely to purchase tactile apparel, and brands commanding 28% price premiums—though it sacrifices fine detail capability and precise color matching

• The printing process requires precise temperature control at 320°F for 60-90 seconds, conveyor dryers for even heat distribution, and careful attention to mesh counts and emulsion thickness for optimal results

• Design considerations include using bold, simple artwork rather than intricate patterns, testing different puff additive concentrations (5-20%), and understanding that halftones can create varying height effects within single designs

• Businesses leveraging puff printing see remarkable returns, with the market reaching $1.2 billion globally in 2024, multipack offerings generating 3.2x higher conversion rates, and organic options capturing premium segments despite 135% higher prices

• Working with experienced providers like Thrive Screen Printing ensures proper design complexity matching and access to comprehensive specialty effects including metallic, foil, and glow-in-the-dark combinations with puff printing

Quick Tip: Start with a 10% puff additive concentration for your first project—this sweet spot provides a noticeable dimension without overwhelming the design, allowing you to gauge customer response before committing to bolder effects.

As we explore the technical foundations, market dynamics, and creative possibilities of dimensional puff printing, you’ll discover why this technique has experienced 237% market growth since 2022 and continues to captivate both designers and consumers alike.

What Makes Dimensional Puff Printing Different from Other Screen Printing Techniques?

Dimensional puff printing creates three-dimensional, tactile surfaces through specialized plastisol-based inks containing heat-activated foaming agents, while traditional screen printing uses standard plastisol, water-based, or discharge inks. This technique requires precise temperature control at 320°F (160°C) for full expansion, compared to the 300-320°F range for standard plastisol curing.

The printing setup differs significantly from conventional methods:

- Mesh count: Uses 80-110 mesh for puff layers versus 150-300+ mesh for standard prints

- Screen preparation: Requires thicker emulsion layers for substantial ink deposits

- Detail capability: Cannot reproduce fine details or intricate patterns that traditional screen printing achieves

- Texture outcome: Expands both vertically and horizontally during curing, creating soft, puffy surfaces

This section explores how the puff effect develops, essential materials needed, and combination possibilities with other specialty techniques.

How Does the Puff Effect Get Created During Printing?

The puff effect develops through heat-sensitive microspheres in the ink that expand when exposed to temperatures between 200-260°F (93-127°C). Standard curing at 320°F (160°C) for 60-90 seconds causes resin particles to soften, expand, and fuse into the characteristic dimensional texture.

The foaming agent releases gas when heated, creating the signature 3D expansion effect. Expansion occurs in both vertical and horizontal directions, resulting in the soft, puffy texture that distinguishes this technique from flat screen printing methods.

What Materials and Inks Are Essential for Puff Printing?

Puff ink contains resin, polyvinyl chloride (PVC), plasticizers, pigments, and specialized additives that enable the expansion effect. Printers can use either puff additive mixed with standard plastisol at 5-20% concentration or pre-mixed puff base formulations.

Concentration Guidelines:

- Lower concentration (5-10%): Suitable for detailed designs with subtle puff effects

- Higher concentration (15-20%): Creates bold, high-profile dimensional effects

Equipment requirements include 65/90/65 triple durometer squeegees for optimal ink transfer and conveyor dryers for even heat distribution during curing.

Can Dimensional Puff Printing Be Combined with Other Specialty Techniques?

Dimensional puff printing combines effectively with metallic, foil, and glow-in-the-dark inks for enhanced visual effects. Halftones create varying puff heights within single designs, while stretch additives improve ink flexibility for garments requiring movement.

Water-based puff inks offer eco-friendly alternatives with virtually no volatile organic compounds (VOCs). These combinations allow designers to layer effects and create complex dimensional graphics that stand out in competitive apparel markets.

The next section examines the specific benefits and drawbacks of choosing dimensional puff printing for your projects.

What Are the Key Benefits and Drawbacks of Dimensional Puff Printing?

Dimensional puff printing offers significant benefits including enhanced consumer appeal and premium pricing potential, but comes with specific limitations in design complexity and color precision. The technique creates unique tactile experiences that consumers increasingly value in today’s competitive apparel market.

Key Benefits:

- Consumer preference: A 2024 market study found 73% of 18-24-year-olds prioritize texture and physical interaction with clothing

- Purchase influence: Research shows 89% of consumers are more likely to purchase apparel with tactile elements

- Premium pricing: Consumers willingly pay a 28% price premium for puff printed products

- Market differentiation: Creates unique tactile surfaces that standard printing cannot replicate

Primary Drawbacks:

- Color limitations: Cannot achieve precise color matching due to air incorporation during expansion

- Design restrictions: Not suitable for fine details or intricate patterns

- Process complexity: Requires specialized equipment and precise temperature control

The following sections explore specific applications, durability considerations, and market trends that influence dimensional puff printing decisions.

Which Design Types and Fabrics Are Best Suited for Puff Printing?

Design types best suited for puff printing include bold, simple graphics that benefit from dimensional emphasis rather than intricate artwork requiring fine detail reproduction. A 2024 industry analysis revealed 68% of top-selling designs feature organic cotton bases with water-based puff inks.

Optimal Design Categories:

- Company logos with thick letter forms

- Text elements requiring emphasis

- Graphic symbols and icons

- Sports numbers and team identifiers

Fabric Compatibility:

- Cotton blends provide excellent ink adhesion

- Organic cotton bases offer premium positioning

- Polyester requires specialized puff formulations

- Heavy-weight fabrics support better expansion

Bold designs with substantial line thickness produce more pronounced puff effects, while thin lines may not expand properly or could break during the heating process.

Are There Limitations in Durability, Washability, or Design Complexity?

Durability limitations for puff printing center on wash care requirements and design complexity constraints that affect long-term performance. Well-executed puff prints withstand 20-50 washes without significant degradation, while recent ink formulations extend durability to over 50 washes.

Durability Factors:

- Ink formulation quality directly impacts longevity

- Proper curing temperature (320°F for 60-90 seconds) ensures adhesion

- Fabric type influences expansion and retention characteristics

Wash Care Requirements:

- Cold or lukewarm water washing preserves puff structure

- Avoid high-heat drying which can damage dimensional effects

- Air drying extends print lifespan significantly

Design complexity must match puff printing process capabilities, as the technique cannot reproduce the fine details achievable with traditional screen printing. Color matching remains challenging compared to standard printing methods due to air incorporation during expansion.

Why Do Brands Choose Puff Printing for Their Apparel?

Brands choose puff printing for its ability to create unique tactile differentiation in competitive apparel markets while commanding premium pricing. The puff print t-shirt market reached $1.2 billion globally in 2024, representing a 237% increase in value since 2022.

Market Growth Indicators:

- Projected compound annual growth rate (CAGR) of 14.3% through 2027

- Gen Z consumers account for 47% of current market share

- Premium positioning allows sustainable profit margins

Strategic Brand Benefits:

- Enhanced brand memorability through tactile interaction

- Premium perception justifying higher retail prices

- Differentiation from competitors using standard printing

- Appeal to texture-conscious younger demographics

The technique’s unique tactile properties create memorable brand experiences that standard printing cannot replicate, making it particularly valuable for merchandise, promotional items, and fashion-forward apparel lines targeting younger consumers.

How Does the Dimensional Puff Printing Process Work Step by Step?

The dimensional puff printing process involves a systematic approach where heat-activated microspheres in specialized plastisol ink expand to create three-dimensional, tactile surfaces. This multi-stage process requires precise temperature control, proper screen preparation, and careful quality monitoring to achieve consistent results.

The process begins with artwork preparation using bold, simple designs suited for dimensional effects. Screen preparation involves applying thick emulsion layers to accommodate substantial ink deposits. The printing stage uses 80-110 mesh screens with puff ink containing heat-sensitive foaming agents. Final curing at 320°F (160°C) for 60-90 seconds activates the expansion effect, creating the signature raised texture that distinguishes puff printing from traditional screen printing methods.

What Are the Stages from Artwork Preparation to Final Curing?

The stages from artwork preparation to final curing follow a precise sequence that ensures optimal puff expansion and durability. Thick emulsion layers are applied to screens for substantial ink deposit, with 80-110 mesh count used for the primary puff layer.

The printing process uses specialized puff ink containing heat-activated foaming agents. Initial ink activation begins at 200-260°F (93-127°C), causing microspheres to start expanding. Full curing requires 320°F (160°C) for 60-90 seconds using a conveyor dryer for consistent heat distribution across the entire print area.

Key Process Stages:

- Screen preparation with thick emulsion application

- Ink mixing with proper puff additive concentration (5-20%)

- Print application through 80-110 mesh screens

- Initial heat activation at 200-260°F

- Final curing at 320°F for 60-90 seconds

- Quality inspection for proper expansion and adhesion

How Does Quality Control Work in Dimensional Puff Printing?

Quality control in dimensional puff printing maintains industry-standard misprint rates through systematic monitoring of temperature, timing, and ink formulation. The industry acceptable misprint rate is 0.005% (few pieces per thousand), while most shops maintain a misprint factor at or below 3%.

Proper curing temperature and time are critical for quality control, as under-curing leads to poor expansion while over-curing can damage the puff effect. Ink quality and formulation directly impact final product durability, requiring consistent batch mixing and regular viscosity testing.

Quality Control Checkpoints:

- Temperature monitoring at 320°F ±5°F tolerance

- Timing verification for 60-90 second cure cycles

- Visual inspection for uniform expansion

- Adhesion testing on sample pieces

- Batch consistency verification for ink mixing ratios

What Common Mistakes Should Be Avoided for Best Results?

Common mistakes in dimensional puff printing stem from improper technical setup and unrealistic design expectations that compromise the final product quality. Avoid using mesh counts too high for proper ink deposit, as this prevents adequate puff ink application needed for expansion.

Temperature control precision prevents under or over-expansion issues that create uneven or damaged puff effects. Fine details or intricate patterns should not be attempted with puff ink, as the expansion process cannot maintain sharp edges or complex geometries. High-heat drying must be avoided as it can damage the puff effect and reduce durability.

Critical Mistakes to Avoid:

- Using mesh counts above 110 for puff layers

- Inconsistent temperature control during curing

- Attempting fine detail work with puff ink

- High-heat drying that damages expanded texture

- Inadequate ink deposit thickness for proper expansion

The dimensional puff printing process requires technical precision and realistic design expectations to achieve professional results that meet quality standards and customer expectations.

What Should You Consider When Designing for Dimensional Puff Printing?

Dimensional puff printing design requires careful consideration of technical constraints and artistic possibilities. Line thickness, color matching, and testing protocols determine whether your artwork achieves the desired three-dimensional effect or falls flat during production.

How Do Line Thickness and Detail Level Affect the Final Look?

Line thickness and detail level directly determine puff printing success. Thicker lines and bolder elements produce more pronounced puff effects because they provide adequate surface area for the foaming agents to expand properly. Fine details and thin lines may not expand properly or could break during the heating process, as the microspheres need sufficient ink volume to create visible dimension.

Halftones can be used to create varying puff heights within designs, offering designers creative control over dimensional gradation. This technique allows for sophisticated effects where different areas of the same design achieve different elevation levels, adding visual depth beyond simple raised surfaces.

Line Thickness Guidelines:

- Bold elements (3mm+ width): Maximum puff effect

- Medium details (1-3mm): Moderate expansion

- Fine lines (<1mm): Risk of breakage or poor expansion

- Halftone areas: Variable height based on dot density

Are There Best Practices for Color, Placement, and Layering?

Color matching presents unique challenges in puff printing due to air incorporation during the expansion process. The foaming effect lightens colors and can create inconsistent tones across the printed surface, making precise color reproduction more challenging than traditional printing methods.

You can layer puff effects with detail layers using up to 305 mesh for non-puff elements, creating hybrid designs that combine dimensional and flat printing techniques. This approach allows designers to maintain fine details while adding dimensional emphasis to key elements.

Placement should consider garment wear areas to prevent premature degradation. High-friction zones like armpit seams, collar edges, and hem areas can cause puff effects to crack or peel with repeated washing and wearing.

Strategic Placement Recommendations:

- Center chest: Ideal for logos and main graphics

- Back panels: Excellent for large dimensional designs

- Sleeves: Good for accent elements

- Avoid: Seam intersections and high-flex areas

How Can Designers Test and Refine Artwork for This Technique?

Design complexity must be matched to puff printing capabilities through systematic testing and refinement. Testing different puff additive concentrations between 5-20% helps achieve the desired effect, with lower concentrations suitable for subtle dimensional effects and higher concentrations creating bold, high-profile results.

Sample runs are recommended to evaluate expansion characteristics before full production. These test prints reveal how specific design elements will behave during the heating process, allowing designers to adjust line weights, spacing, and overall composition for optimal results.

Testing Protocol Steps:

- Create test squares with varying additive concentrations

- Test different mesh counts (80-110) for ink deposit thickness

- Evaluate expansion at different temperature settings

- Document successful combinations for production reference

This systematic approach ensures your final design achieves the intended dimensional effect while maintaining production efficiency and quality standards.

How Can Businesses Leverage Dimensional Puff Printing for Branding and Merch?

Businesses can leverage dimensional puff printing as a strategic differentiator that transforms standard apparel into premium branded merchandise with tactile appeal. This technique creates unique brand touchpoints that command higher prices while building stronger customer connections through physical texture experiences.

The three key areas where businesses maximize puff printing value are product selection, brand positioning, and customization strategies. Companies using dimensional effects report enhanced brand memorability and willingness among consumers to pay premium prices for textured merchandise.

What Types of Apparel or Products Most Benefit from Puff Printing?

T-shirts represent the largest market segment for puff printing, accounting for the majority of dimensional printing applications. Products with GOTS certification capture premium market segments where consumers prioritize both sustainability and unique design elements. According to 2024 market analysis, organic multipacks generate 2.2x higher monthly sales despite commanding a 135% higher price point than conventional alternatives.

High-Performance Product Categories:

- Logo-centric apparel where brand identity benefits from dimensional emphasis

- Youth and Gen Z-targeted merchandise that prioritizes tactile interaction

- Limited edition releases where unique texture creates collectible value

- Corporate gifts and promotional items requiring memorable brand impact

Premium positioning works best for products where the dimensional effect enhances rather than competes with the core design message.

How Does the Unique Texture Impact Perceived Brand Value?

The unique texture creates premium perception allowing brands to implement a 28% price increase over standard printing methods. Multipack offerings featuring puff printing generate 3.2x higher conversion rates than single units, demonstrating strong consumer preference for tactile differentiation. Research shows 89% of consumers express greater likelihood to purchase apparel featuring tactile elements compared to flat printing alternatives.

Brand Value Enhancement Areas:

- Memorability: Physical texture creates lasting sensory memory beyond visual recognition

- Quality Perception: Dimensional effects signal craftsmanship and attention to detail

- Social Media Appeal: Textured surfaces photograph distinctively for user-generated content

- Repeat Purchase Behavior: Tactile satisfaction drives higher customer retention rates

Tactile differentiation increases brand memorability and customer engagement by creating multi-sensory brand experiences that standard printing cannot replicate.

What Quantities and Customization Options Are Typically Available?

Pre-mixed puff bases prove ideal for standardized production runs requiring consistent dimensional effects across large quantities. Puff additives offer creative flexibility for custom effects, allowing businesses to achieve various dimensional levels through 5-20% additive concentration adjustments. Lower concentrations (5-10%) suit detailed designs with subtle texture, while higher concentrations (15-20%) create bold, high-profile dimensional effects.

Production Flexibility Options:

- Small Runs: Custom additive mixing for prototype development and limited releases

- Medium Volumes: Pre-mixed bases for consistent brand merchandise programs

- Large Scale: Standardized formulations for retail distribution and corporate orders

- Multi-Effect Combinations: Layering puff with metallic, foil, or glow effects for premium positioning

Businesses can scale from sample runs testing market response to full production implementing successful dimensional branding strategies across their entire merchandise portfolio.

How Should You Approach Dimensional Puff Printing Projects with Thrive Screen Printing?

Approaching dimensional puff printing projects with Thrive Screen Printing requires understanding their specialized expertise in Phoenix’s competitive custom apparel market. Thrive Screen Printing has established itself as a leader in the dimensional puff printing sector, combining technical precision with creative flexibility to deliver standout results.

The foundation of successful puff printing projects lies in matching design complexity to the process capabilities. Thrive Screen Printing emphasizes this alignment during initial consultations, ensuring that client expectations align with the technical requirements of dimensional puff printing. This approach prevents common issues like inadequate expansion or design degradation that can occur when complex artwork exceeds the technique’s limitations.

Their methodology focuses on three core principles: design optimization for puff effects, precise temperature control during the curing process, and quality assurance throughout production. These elements combine to create the tactile, three-dimensional results that distinguish puff printing from standard screen printing techniques. The following sections explore Thrive’s custom order capabilities and key project considerations.

Can Thrive Screen Printing Help with Custom Dimensional Puff Printing Orders?

Thrive Screen Printing can help with custom dimensional puff printing orders through their comprehensive specialty effects portfolio. The company offers metallic, foil, glow-in-the-dark, and puff printing services, positioning them as a full-service provider for complex custom apparel projects.

Located in Phoenix, Thrive brings specialized expertise in 3D puff screen printing to create standout custom apparel. Their technical capabilities include:

- Multi-effect combinations: Layering puff printing with metallic or glow-in-the-dark inks for enhanced visual impact

- Variable puff heights: Using halftone techniques and additive concentration adjustments (5-20%) to create dimensional variation within single designs

- Custom color development: Working within puff printing’s color limitations to achieve brand-appropriate results

- Production scaling: Handling both small custom runs and larger commercial orders

The company’s Phoenix location provides strategic access to the Southwest market while maintaining the technical infrastructure necessary for consistent puff printing results. Their equipment includes conveyor dryers for proper heat distribution and specialized squeegee configurations optimized for the thicker ink deposits required in dimensional printing.

What Are the Key Takeaways About Exploring Dimensional Puff Printing – Deep Dive We Covered?

The key takeaways about exploring dimensional puff printing center on understanding the technique’s unique characteristics and market position. Dimensional puff printing creates three-dimensional, tactile surfaces through heat-activated foaming agents that expand at 320°F, distinguishing it from traditional flat screen printing methods.

Technical Requirements:

- Uses 80-110 mesh screens versus 150-300+ for standard printing

- Requires precise temperature control and specialized ink formulations

- Works best with bold, simple designs rather than intricate artwork

Market Performance:

- The global puff print market reached $1.2 billion in 2024 with 237% growth since 2022

- Consumers pay 28% premium for puff-printed products

- Gen Z represents 47% of market share, driving demand for tactile apparel

Design Considerations:

- Design complexity must match process capabilities

- Color matching presents challenges due to air incorporation during expansion

- Durability ranges from 20-50+ washes with proper care

Business Applications:

- Creates premium brand perception and differentiation

- Ideal for logos, text, and graphic elements requiring dimensional emphasis

- Combines effectively with other specialty techniques for enhanced effects

These insights demonstrate that dimensional puff printing serves as both a technical printing method and a strategic branding tool for businesses seeking to create memorable, tactile products in the competitive custom apparel market.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.