If you’re searching for the best screen printing inks for your Phoenix project, you’ve come to the right place. Whether you’re creating custom t-shirts for your local business, designing uniforms that can withstand Arizona’s intense sun, or producing promotional materials for your next event, understanding ink types is crucial for achieving professional results that last. We’ll guide you through everything you need to know about screen printing inks specifically for Phoenix’s unique climate and market demands.

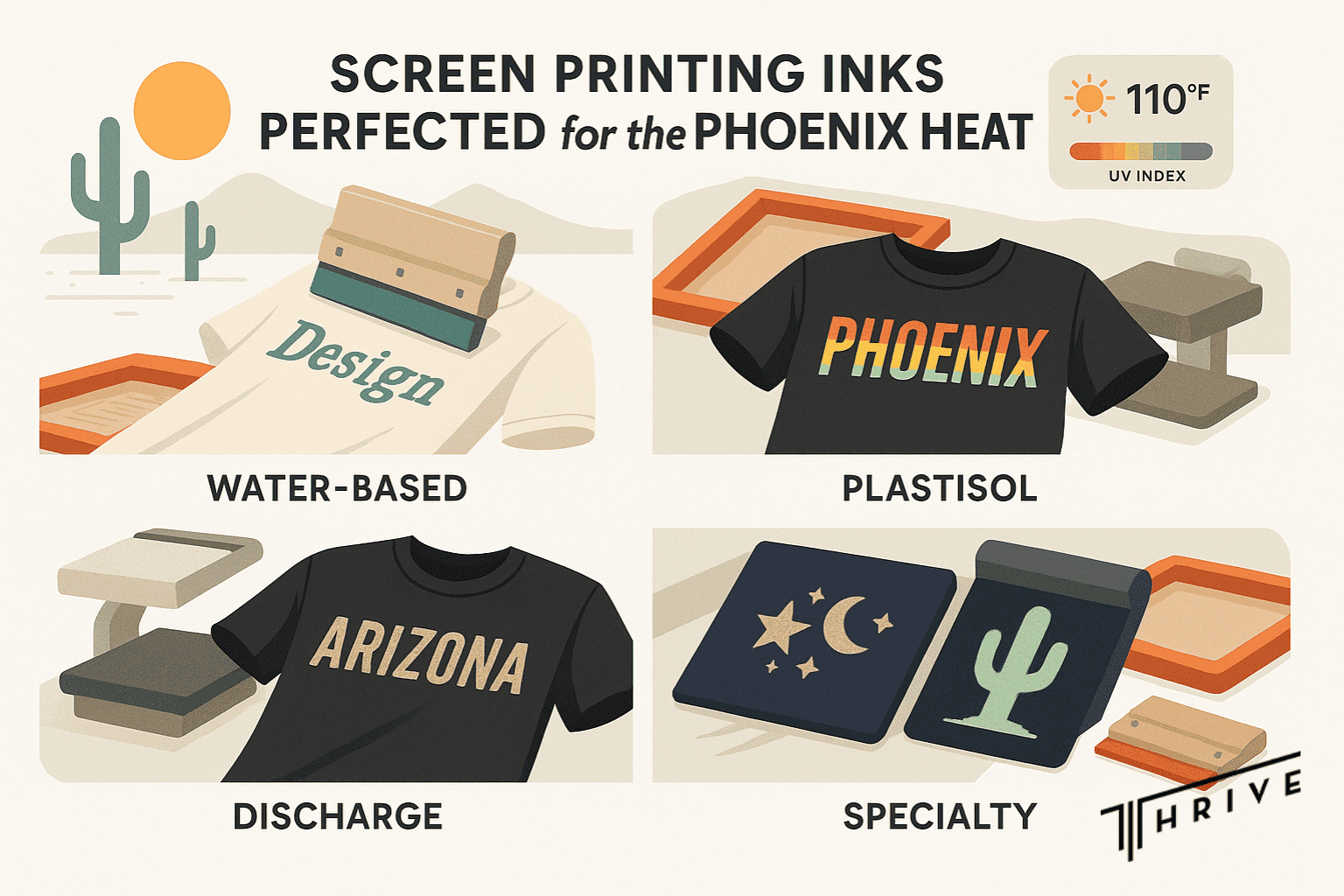

Types of screen printing inks used in Phoenix encompass four main categories: water-based inks that penetrate fabric fibers for soft, breathable prints; plastisol inks that create durable, vibrant designs on various materials; discharge inks that remove and replace fabric dye for vintage effects; and specialty inks including metallic, glow-in-the-dark, and puff options for unique dimensional effects.

TL;DR Summary:

• Main ink categories include water-based (33% market share), plastisol (67% market share), discharge, and specialty inks, each offering distinct advantages for different applications and fabrics.

• Phoenix’s desert climate significantly impacts ink selection – extreme heat up to 110°F affects curing processes, low humidity causes water-based inks to dry quickly in screens, and intense UV radiation requires fade-resistant formulations for outdoor durability.

• Each ink type has specific pros and cons – water-based inks offer eco-friendly soft prints but dry in screens; plastisol provides versatility and wet-on-wet printing but creates a tangible film; specialty inks enable unique effects for customized apparel.

• Fabric and project requirements determine optimal ink choice – 100% cotton works best with water-based and discharge inks, polyester requires plastisol’s bleed resistance, while outdoor workwear needs UV-stable formulations.

• Professional testing and consultation ensures quality results – Thrive Screen Printing’s 40,000-square-foot Phoenix facility offers comprehensive ink options and expertise, with proper testing protocols including wash, light, and rub fastness evaluations.

Quick Tip: For Phoenix’s extreme heat, always use infrared thermometers to monitor curing temperatures precisely – over-curing at temperatures above 330°F can scorch fabrics, while under-curing below 300°F leads to prints that crack and peel prematurely.

As we explore the nuances of screen printing ink selection in Phoenix, you’ll discover how local environmental factors, market demands, and technical specifications all play vital roles in achieving exceptional print quality. From understanding VOC compliance regulations in Maricopa County to leveraging specialty inks for Phoenix’s growing custom apparel market, this comprehensive guide equips you with the knowledge to make informed decisions for your screen printing projects.

What Are the Main Categories of Screen Printing Inks Available?

Screen printing inks divide into four main categories: water-based, plastisol, discharge, and specialty formulations. Each type offers distinct performance characteristics, curing requirements, and applications suited for different fabric types and printing environments. Phoenix printers must consider these categories alongside the desert climate’s unique challenges when selecting optimal ink systems for their projects.

How Do Water-Based Inks Work in Screen Printing?

Water-based inks are solvent systems using water to carry pigments that penetrate fabric fibers rather than forming surface layers. These inks cure through water evaporation during air-drying or heat-setting processes.

Key performance characteristics include:

- Lower volatile organic compound (VOC) emissions compared to plastisol systems

- Soft hand feel with breathable finish on completed garments

- Screen drying challenges requiring careful production timing

- Optimal performance on 100% cotton fabrics through natural fiber absorption

According to 2023 global market data, water-based inks represented 33% of screen printing ink volume exceeding 1.8 million tonnes, with pricing at USD 2-4 per kg—slightly higher than solvent alternatives.

Water-based systems provide environmentally conscious printing solutions while delivering detailed, long-lasting prints ideal for cotton garments requiring comfort and breathability.

What Are Plastisol Inks and Why Are They Popular?

Plastisol ink is a polyvinyl chloride (PVC) system that is 100% solid with no solvents. This formulation requires heat curing at temperatures between 300°F to 330°F (148°C to 165°C) to achieve proper adhesion and durability.

Production advantages include:

- No screen drying during printing, enabling wet-on-wet techniques

- Increased production speed through continuous printing capability

- Versatile performance across various fabric types including polyester blends

- Good bleed resistance properties for synthetic fabrics

A 2023 industry analysis showed plastisol inks captured 67% of the global screen printing ink market. Thrive Screen Printing utilizes plastisol systems for their adaptability, durability, and accurate color representation across diverse Phoenix printing projects.

Plastisol creates a tangible ink film on fabric surfaces, making it particularly suitable for designs requiring opacity and vibrant color reproduction on both light and dark garments.

How Are Discharge Inks Used for Garment Printing?

Discharge ink contains water-based components with bleaching agents that remove existing fabric dye while simultaneously depositing new color. This process requires curing temperatures of 320°F to 330°F (160°C to 165°C) for proper activation.

Performance characteristics include:

- No-hand feel as ink becomes integrated within fabric structure

- Vintage appearance with extremely soft, breathable prints

- Optimal results on 100% cotton fabrics containing reactive dyes

- Unpredictable performance on cotton/polyester blend materials

Thrive Screen Printing recommends discharge ink for dark garments and activewear applications where comfort and breathability are priorities. The process works most effectively on pure cotton substrates, producing prints that maintain fabric flexibility and natural drape.

Discharge printing creates unique aesthetic results impossible with surface-applied inks, making it ideal for premium garments requiring both visual appeal and wearing comfort.

What Makes Specialty Inks (Metallic, Glow, Puff) Unique?

Specialty inks incorporate unique additives creating distinctive visual and tactile effects beyond standard color reproduction. These formulations serve specific design requirements and market niches.

Metallic inks contain reflective particles producing shimmering effects, performing best on natural textile substrates. Glow-in-the-dark inks utilize phosphorescent pigments that absorb and emit light, making them ideal for event shirts and novelty applications.

Puff inks create raised, three-dimensional surface effects through expansion during curing. These inks work optimally on heavier fabrics with bold design shapes that accommodate dimensional changes.

Thrive Screen Printing’s 40,000-square-foot Phoenix facility offers comprehensive specialty ink options, responding to market demand for customized and unique apparel throughout the Phoenix area.

Specialty ink selection requires careful consideration of substrate compatibility, design complexity, and intended use to achieve optimal visual impact and durability performance.

How Do Environmental and Climate Factors in Phoenix Affect Ink Selection?

Phoenix’s extreme desert climate creates unique challenges for screen printing operations that directly influence ink selection and performance. The combination of intense heat, low humidity, and extreme UV exposure requires careful consideration of ink chemistry and printing processes. Understanding these environmental factors helps screen printers select appropriate inks and modify techniques to maintain consistent, high-quality results in Arizona’s challenging conditions. This section examines specific climate impacts and provides guidance for adapting printing processes to Phoenix’s demanding environment.

Why Does the Desert Climate Influence Ink Performance?

The desert climate influences ink performance because Phoenix’s extreme heat and low humidity dramatically alter ink behavior during printing and curing processes. Phoenix shop temperatures can reach 110°F, creating risks of over-curing that scorches fabric and damages prints. Low humidity causes water-based inks to dry out too quickly on screens, leading to clogged mesh openings and inconsistent ink deposits.

Desert conditions create several operational challenges:

- Screen clogging from rapid water evaporation

- Inconsistent print opacity and coverage

- Increased ink waste from premature drying

- Production delays from frequent screen cleaning

Printers must regulate humidity in print rooms to combat moisture levels below 20%, often installing humidification systems to maintain optimal conditions. According to North America screen printing data from 2023, the region accounted for 19% of global ink volume at an average price of USD 2.7 per kg, with climate control representing a significant operational cost factor.

What Considerations Exist for Ink Drying Times in Arizona?

Ink drying time considerations exist because high ambient temperatures make controlling the curing process extremely difficult in Phoenix facilities. Under-curing in extreme heat leads to cracked and peeling prints as rapid temperature changes stress the ink film before complete polymerization occurs.

Critical drying time factors include:

- Conveyor belt speed adjustments for temperature variations

- Flash cure station timing modifications

- Ink flow rate changes due to viscosity shifts

- Extended cooling periods before handling

Precision-controlled conveyor dryers and infrared thermometers are essential for managing curing temperatures within the narrow 300-330°F range required for plastisol inks. Flash curing control helps manage rapid drying of water-based inks by providing controlled heat exposure in stages. Adjusting mesh count and emulsion thickness improves ink flow in low humidity conditions by creating larger openings and reducing surface tension effects.

How Do UV and Heat Impact Screen Printing Results?

UV and heat impact screen printing results by causing rapid color degradation and physical breakdown of ink films on garments exposed to Phoenix’s intense solar radiation. The city receives over 300 sunny days annually with UV index levels regularly exceeding 10 during summer months, causing prints to fade within weeks without proper protection.

UV exposure effects include:

- Color shifting toward yellow and red spectrums

- Loss of print opacity and vibrancy

- Surface chalking and ink film deterioration

- Reduced wash fastness and durability

Fade-resistant inks containing UV stabilizers and light-fast pigments are crucial for outdoor apparel durability in Phoenix applications. Light fastness testing measures resistance to fading from daylight exposure using standardized AATCC procedures. For workwear and uniforms constantly exposed to sun, alternative decoration methods like embroidery or heat transfers may provide superior longevity compared to traditional screen printing inks in Phoenix’s extreme UV environment.

What Are the Pros and Cons of Each Screen Printing Ink Type?

Each screen printing ink type offers distinct advantages and limitations that affect project outcomes, cost, and environmental impact. Water-based inks provide eco-friendly solutions with superior comfort, while plastisol inks deliver versatility and production efficiency. Specialty inks enable unique effects for creative applications in Phoenix’s growing custom apparel market.

What Are the Benefits and Drawbacks of Water-Based Inks?

Water-based inks are eco-friendly printing solutions that offer superior comfort and breathability for garments. These inks contain lower volatile organic compounds (VOCs), feature biodegradable properties, and create a soft hand feel with breathable finishes that customers prefer.

Key Benefits:

- Environmental sustainability with reduced VOC emissions

- Soft, breathable finish that feels natural on skin

- Excellent absorption into 100% cotton fabrics

- Long-lasting, detailed print capabilities according to Thrive Screen Printing

Primary Drawbacks:

- Higher operational difficulty as inks dry in screens during production

- Increased drying capacity requirements compared to plastisol alternatives

- Premium pricing at USD 2-4 per kg versus USD 1.5-3 per kg for solvent-based inks in 2023

Water-based inks work best for cotton garments where comfort and environmental responsibility are priorities, though they require more skilled handling and equipment investment.

What Are the Advantages and Disadvantages of Plastisol Inks?

Plastisol inks are versatile, user-friendly printing solutions that dominate commercial screen printing operations. These PVC-based inks remain wet on screens indefinitely, enabling continuous production without interruption or cleanup between jobs.

Primary Advantages:

- Exceptional versatility for various fabric types including polyester blends

- No screen drying allows uninterrupted production workflows

- Wet-on-wet printing capability increases production speed significantly

- Cost-effectiveness and accurate color reproduction noted by Thrive Screen Printing

Notable Disadvantages:

- Tangible ink film creates less comfortable feel on garments

- Environmental concerns compared to water-based alternatives

- Heat curing requirement at 300°F to 330°F increases energy costs

Plastisol inks excel for high-volume production runs and polyester fabrics, though environmental considerations and hand feel may limit applications for premium or eco-conscious projects.

How Are Specialty Inks Best Utilized in Phoenix?

Specialty inks create unique visual effects that command premium pricing in Phoenix’s custom apparel market. Metallic inks deliver shimmer effects on natural textiles, while glow-in-the-dark options serve novelty and event applications perfectly.

Optimal Applications:

- Metallic inks perform best on natural textiles requiring bold, shimmering designs

- Glow-in-the-dark inks excel for novelty items and event shirts in Phoenix’s entertainment market

- Puff inks demand heavier fabric substrates and bold shapes for successful three-dimensional effects

- Market research shows growing demand for customized specialty printing in the Phoenix area

Thrive Screen Printing’s 40,000-square-foot Phoenix facility stocks various specialty ink options, positioning the company to serve diverse creative projects. These specialty applications typically require careful substrate selection and precise application techniques for optimal results.

How Do You Choose the Right Screen Printing Ink for Your Project?

Choosing the right screen printing ink depends on fabric type, design requirements, and intended use. Your project’s success hinges on matching ink properties to substrate characteristics and performance expectations. This section examines fabric considerations, application requirements, and testing protocols that guide professional ink selection.

What Fabric and Design Factors Influence Ink Choice?

Fabric composition determines ink compatibility and performance outcomes. 100% cotton serves as the ideal substrate for discharge and water-based inks due to natural fiber absorption properties that allow proper penetration. Polyester requires inks with good bleed resistance like plastisol or specially formulated water-based inks that prevent dye migration.

Cotton/polyester blends work well with plastisol inks but show unpredictable results with discharge ink applications. Bold designs featuring metallic effects perform best on natural textiles where metallic particles can properly adhere. Heavy fabrics provide necessary support for successful puff ink applications that create three-dimensional effects.

Design complexity also influences selection—detailed artwork benefits from water-based inks’ fine print capabilities, while simple graphics suit plastisol’s opacity and coverage.

How Does Intended Use (Apparel, Promo Items) Affect Ink Selection?

Application environment drives ink selection for optimal durability and performance. Outdoor workwear in Phoenix requires fade-resistant inks with color stabilizers due to intense UV exposure that can degrade standard formulations. Activewear benefits from discharge ink’s soft, breathable properties that maintain comfort during physical activity, according to Thrive Screen Printing’s recommendations.

Event shirts and novelty items suit glow-in-the-dark specialty inks that create memorable visual effects. Uniforms constantly exposed to sun may need alternatives like embroidery or heat transfers when ink durability proves insufficient. Dark garments achieve best results with discharge ink for soft, durable designs that won’t crack or peel.

Consider washing frequency, wear conditions, and expected lifespan when matching ink properties to garment purpose.

What Is the Process for Testing Inks Before Large Runs?

Professional testing protocols ensure ink performance meets project requirements through standardized evaluation methods. Wash fastness testing evaluates print resistance to washing cycles using controlled temperature and detergent conditions. Light fastness testing measures resistance to fading from daylight exposure using calibrated UV lamps.

Testing procedures include:

- Rub/crock fastness assessment of color transfer when fabric is rubbed

- Perspiration fastness measurement of color transfer from human perspiration

- Martindale rub test evaluation of abrasion resistance and fabric durability

- Simplified crock test using white cotton fabric rubbed against prints

Wash testing provides the most reliable method to determine ink adhesion quality and long-term performance expectations. These protocols prevent costly production errors and ensure customer satisfaction with finished products.

How Should You Approach Selecting Screen Printing Inks in Phoenix with Thrive Screen Printing?

Can Thrive Screen Printing Help You Determine the Best Ink for Your Needs?

Thrive Screen Printing helps determine the best ink for your needs through their comprehensive consultation process and diverse ink portfolio. Their 40,000-square-foot Phoenix facility serves small businesses to global enterprises with plastisol, water-based, discharge, and specialty ink options.

The company utilizes plastisol for adaptability, durability, and accurate color representation across various projects. Water-based ink printing offers eco-friendly properties with detailed print capabilities for environmentally conscious clients. Discharge ink works specifically for dark garments and activewear applications where soft hand feel matters most.

Thrive’s Ink Selection Services:

- Project consultation matching ink type to fabric and design requirements

- Sample testing before large production runs

- Specialty options including metallic, glow-in-the-dark, and puff inks

- Technical guidance for Phoenix climate considerations

Their expertise helps navigate ink selection challenges unique to Phoenix’s desert environment while ensuring optimal results for your specific application.

What Are the Key Takeaways About Types of Screen Printing Inks Used in Phoenix We Covered?

The key takeaways about screen printing inks in Phoenix center on market growth, regulatory compliance, and local demand patterns. The global screen printing inks market reached USD 702.77 million in 2024 and projects to USD 885.33 million by 2033, reflecting strong industry expansion.

Maricopa County Rule 337 limits VOC emissions to 3.3 lbs/gal (400 grams/liter) for inks and coatings, requiring Phoenix facilities to report emissions through the AQD Online Portal. Cold press screen printing considers only 5% of VOC content as emissions, making it advantageous for compliance.

Market and Economic Factors:

- Pigment prices increased 12-18% in 2023, impacting overall ink costs

- Strong market demand for diverse printing options in Phoenix

- Growing interest in customized apparel solutions

- Regulatory compliance driving water-based ink adoption

These factors shape ink selection decisions for Phoenix screen printers, balancing cost, performance, and environmental requirements. Understanding market trends and regulations helps ensure successful project outcomes while maintaining compliance with local air quality standards.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.