If you’re researching screen frames for your Phoenix screen printing operation, you’re likely wondering whether the traditional wood frames or modern aluminum options will better withstand our extreme desert climate while delivering the print quality your customers demand. We understand this critical decision impacts everything from your initial investment to long-term profitability, and we’re here to help you make the right choice for your specific needs.

Screen frames for screen printing in Phoenix face unique challenges from extreme heat exceeding 100°F for over 100 days annually and humidity levels dropping below 20%, making frame material selection crucial for maintaining print quality and operational efficiency. At Thrive Screen Printing, we’ve navigated these exact conditions while serving major clients from our 40,000-square-foot facility, and we’ll share the insights that help Phoenix screen printers make informed frame investments.

TL;DR Summary: Wood frames dominate 70% of the market with lower initial costs ($27-$40) but suffer from moisture absorption and warping in Phoenix’s climate. Aluminum frames using 6063-T5 alloy cost more upfront ($42.50+) but offer superior strength (186 MPa tensile strength), chemical resistance, and 40+ year lifespans. Phoenix’s extreme temperatures and low humidity amplify wood’s weaknesses during the wet reclaiming process, causing rapid deterioration. Professional Phoenix printers overwhelmingly choose aluminum for its consistent mesh tension, re-stretchability, and stability despite higher initial investment. Environmental sustainability favors aluminum’s infinite recyclability and reduced replacement frequency. For Phoenix screen printing operations prioritizing quality and long-term value, aluminum frames prove the optimal choice despite higher upfront costs.

Quick Tip: When evaluating frame options, calculate total cost of ownership over 5 years including replacements, maintenance, and production downtime – aluminum’s durability often makes it the more economical choice despite higher initial price.

The foundation of exceptional screen printing lies in frame stability, and in Phoenix’s challenging environment, this choice becomes even more critical for maintaining the consistency your clients expect.

What Are the Main Differences Between Wood and Aluminum Screen Frames for Screen Printing?

Wood and aluminum screen frames differ fundamentally in construction, durability, and performance characteristics. Wood frames represent over 70% of the market and are typically constructed from soft pine or feature glued mortise and tenon corners for higher-quality versions. Aluminum frames most commonly use 6063-T5 alloy, which offers a balance of strength, corrosion resistance, and extrudability.

The material properties create distinct performance profiles. Wood frames are coated with water-repellent paints or polyurethane to mitigate natural porosity, while aluminum is impervious to water and chemicals, preventing warping, swelling, or rotting. Aluminum frames require surface preparation by sanding, grinding, or sandblasting for proper mesh adhesion.

| Material | Tensile Strength | Density | Thermal Expansion |

| Aluminum (6063-T5) | 186 MPa (27,000 psi) | 2.7 g/cc | 23.4 µm/m-°C |

| Wood (varies) | Variable by type/grain | 420 kg/m³ (Sitka spruce) | 20-70 x 10⁻⁶ /°C |

These differences directly impact frame selection for professional applications. The following subsections examine how these material characteristics affect print quality, durability, and performance in Phoenix’s extreme climate.

How Do Wood and Aluminum Screen Frames Affect Print Quality?

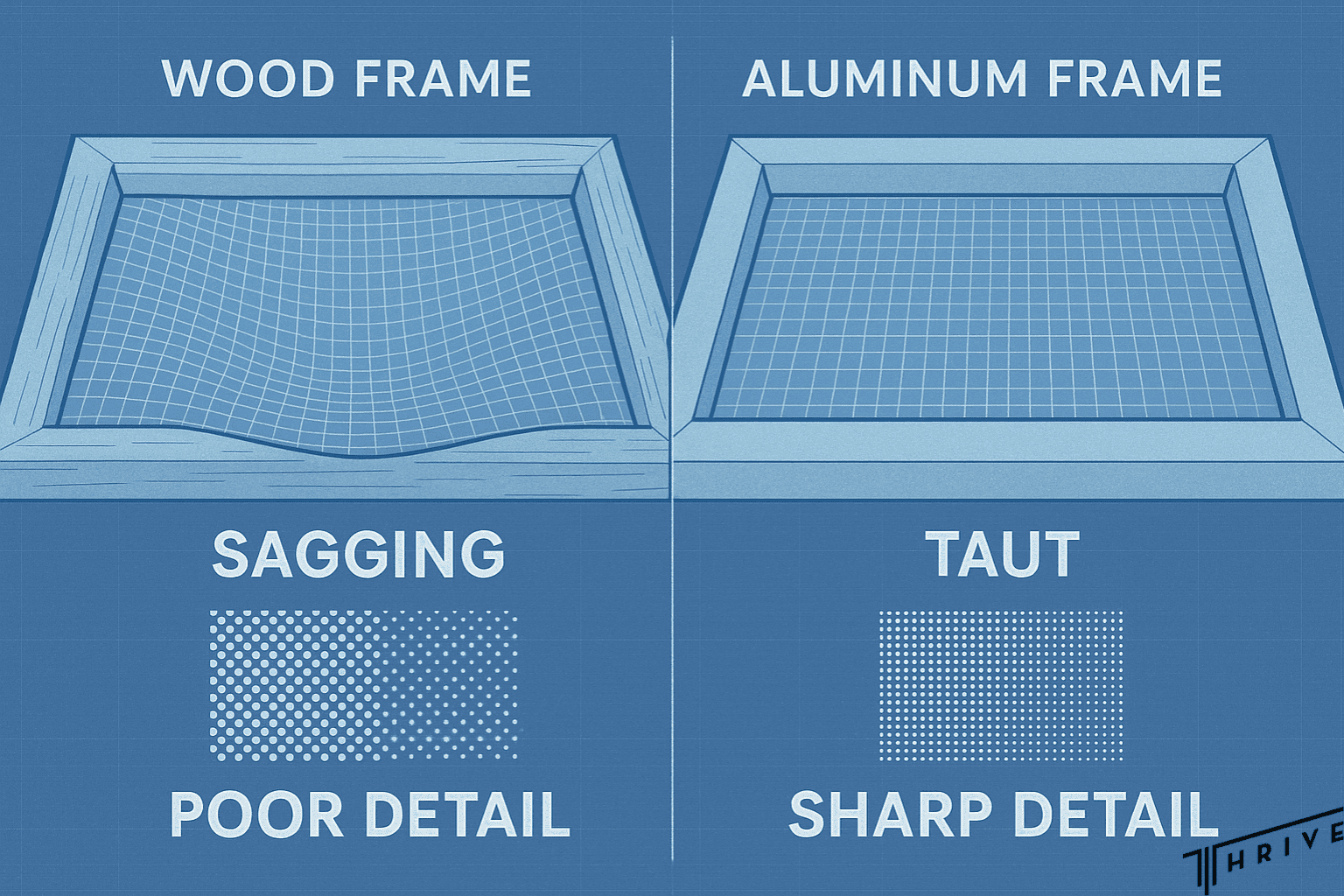

Wood and aluminum screen frames affect print quality through their ability to maintain proper mesh tension during printing operations. Low screen tension from frame instability leads to poor ink transfer, loss of detail, and misregistration across production runs.

Aluminum frames hold significantly higher mesh tension than wood frames due to superior strength and rigidity. Wood frames experience tension loss from moisture and temperature changes, making them less suitable for high-tolerance printing applications. Higher mesh tension in aluminum frames allows for finer detail, better ink control, and more precise registration in multi-color designs.

The stability difference becomes critical during extended production runs where consistent tension maintains print quality throughout the entire job.

What Is the Lifespan of Wood vs Aluminum Screen Frames?

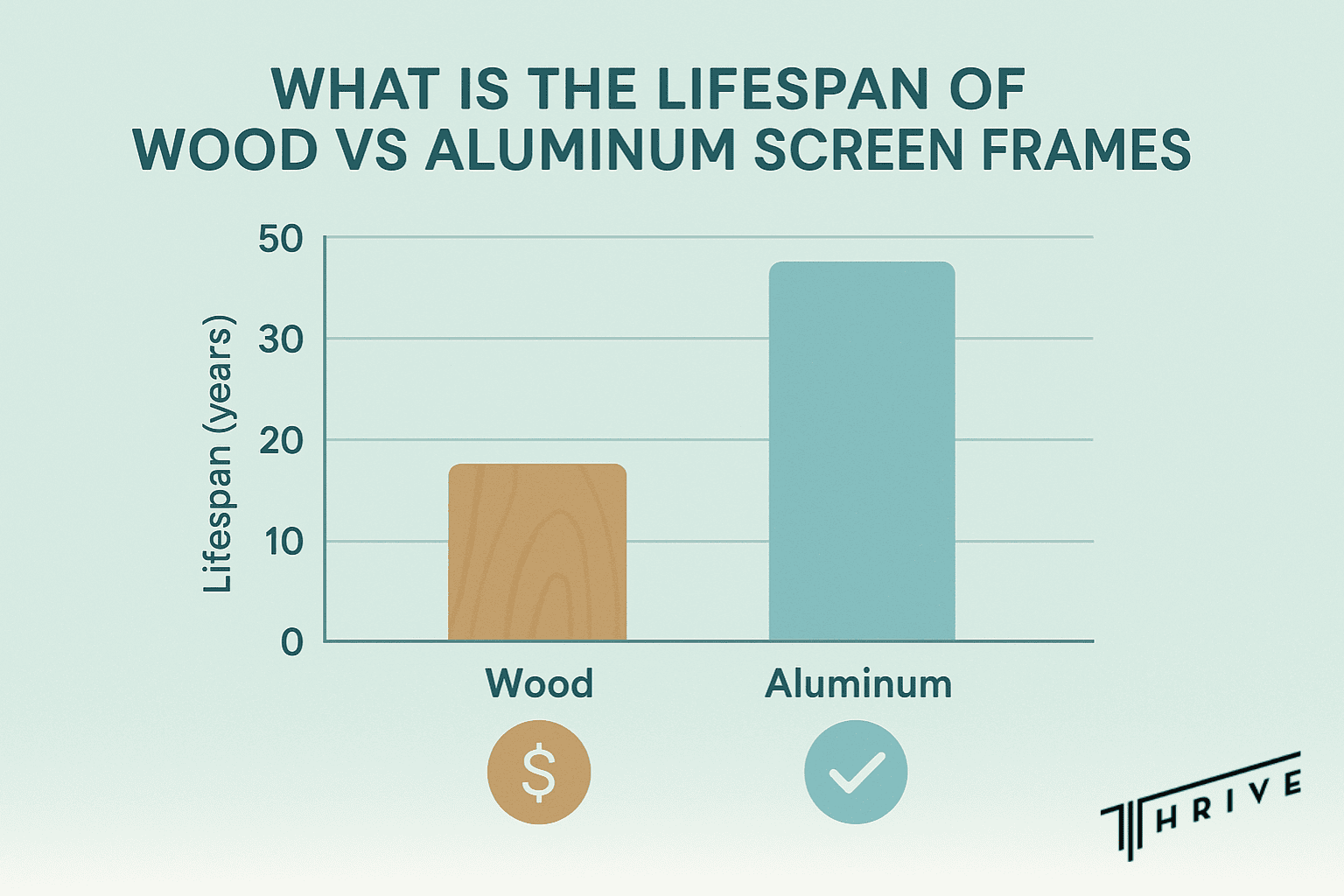

The lifespan of wood vs aluminum screen frames varies significantly due to material durability and environmental resistance. Wood frames have an estimated lifespan of 20-30 years with high variability depending on usage conditions and maintenance practices.

Aluminum frames can last 40+ years with proper care and demonstrate superior longevity characteristics. Aluminum frames can be re-stretched multiple times, extending usable life beyond wood frames through repeated mesh replacements. Static aluminum frames experience tension loss over time from mesh fabric relaxation but maintain structural integrity for re-stretching operations.

This durability difference creates substantial long-term cost implications for screen printing operations, particularly in high-volume commercial environments.

How Does Each Material Perform in the Phoenix Climate?

Each material performs differently in the Phoenix climate due to extreme heat and low humidity conditions throughout the summer months. Phoenix experiences average summer temperatures of 95°F with over 100 days exceeding 100°F annually, while relative humidity drops below 20% during summer months.

Wood frames rarely return to original shape if bent while wet during screen reclaiming processes. Extreme heat reduces wood strength, increasing susceptibility to deflection under tension and accelerating deterioration. Aluminum frames remain stable and warp-free despite repeated water exposure during reclaiming in desert heat.

Thermal expansion of aluminum is predictable and uniform without compromising structural integrity, while wood’s variable expansion creates dimensional instability that affects print registration and quality consistency.

What Are the Pros and Cons of Wood Screen Frames for Screen Printing?

Wood screen frames present both budget advantages and performance limitations for screen printing operations. Wood frames offer the lowest initial purchase price, ranging $27-$40 for a 23″x31″ frame, making them accessible for budget-conscious operations. However, wood’s natural properties create significant drawbacks: protective coatings degrade when exposed to common screen printing cleaning chemicals, wood absorbs moisture leading to warping and potential rotting, and environmental changes cause frame tension loss that directly affects print quality. Wood frames can be recycled at end of life after mesh removal.

The following sections examine specific scenarios for wood frame use, maintenance requirements, and environmental considerations in Phoenix’s challenging climate.

When Should You Choose Wood Screen Frames in Phoenix?

Wood frames may suit hobbyists or small-scale operations with limited budgets. Initial cost savings make wood frames accessible for startups or occasional printing needs. However, Phoenix’s extreme heat and low humidity amplify wood’s natural weaknesses, making them less suitable for professional operations requiring consistent results.

What Maintenance Do Wood Screen Frames Require?

Wood screen frames require extensive maintenance in Phoenix’s harsh climate. Estimated annual maintenance costs for wood frames range from $100-$300. Wood frames require frequent inspection for warping, cracking, and tension loss. Protective coating reapplication is needed as chemicals degrade water-repellent finishes. Rapid drying after wet reclaiming in Phoenix’s arid air accelerates warping and cracking, increasing maintenance frequency beyond typical expectations.

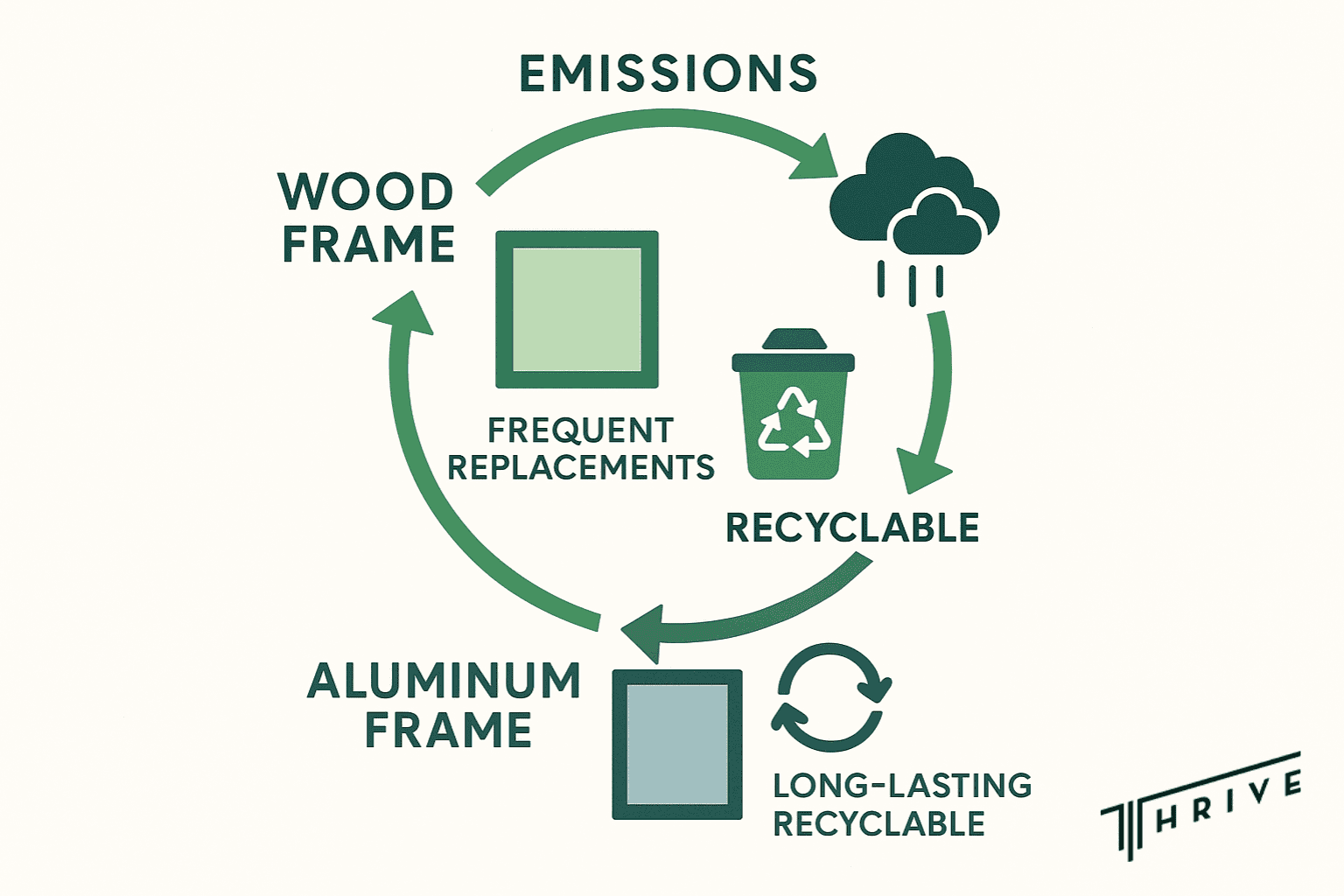

Are There Environmental Concerns with Wood Frames in Screen Printing?

Wood frames present mixed environmental implications. Wood frames can be recycled when they reach end of life, providing sustainable disposal options. However, frequent replacement of damaged wood frames increases manufacturing and transportation emissions. Wood frame durability issues lead to higher waste generation compared to aluminum, offsetting recyclability benefits through increased replacement cycles.

This analysis of wood frame pros and cons reveals significant limitations in Phoenix’s climate, leading to considerations of alternative materials for professional screen printing operations.

What Are the Advantages and Disadvantages of Aluminum Screen Frames?

Aluminum screen frames offer superior durability and performance but require higher upfront investment compared to wood alternatives. These frames cost upwards of $42.50 for a 23″x31″ size, reflecting their premium construction using 6063-T5 alloy with a tensile yield strength of 145 MPa (21,000 psi). The higher initial cost is offset by exceptional durability, longevity, and lower maintenance requirements throughout the frame’s extended lifespan.

Key advantages include:

- Consistent performance regardless of humidity fluctuations

- Infinite recyclability without quality loss, requiring only 5% of energy needed for new aluminum production

- Superior strength allowing higher mesh tension for better print quality

- Re-stretchability for extended operational life

The primary disadvantage centers on cost, as aluminum frames require significantly more upfront capital than wood options. However, this investment delivers better long-term value through reduced replacement frequency and maintenance needs. The following sections examine specific scenarios where aluminum frames excel and their cost implications for Phoenix screen printers.

Why Might Aluminum Frames Be Preferred for High-Volume Printing?

Aluminum frames excel in high-volume printing operations due to their exceptional stability and consistent mesh tension capabilities. Aluminum’s stability ensures consistent mesh tension for accurate registration in multi-color jobs, eliminating the variability that causes registration problems in complex designs. Professional screen printers show strong preference for aluminum due to performance and durability advantages that directly impact production efficiency.

The re-stretchability of aluminum frames reduces replacement frequency in high-volume operations, allowing shops to maintain consistent frame inventory without frequent restocking. This capability proves especially valuable during peak production periods when frame availability affects throughput and delivery schedules.

How Durable Are Aluminum Screen Frames in Harsh Phoenix Conditions?

Aluminum screen frames demonstrate exceptional durability in Phoenix’s extreme desert environment. Aluminum’s resistance to moisture and temperature fluctuations ensures stability in Phoenix’s conditions, where summer temperatures exceed 100°F for over 100 days annually. Aluminum frames maintain structural integrity in temperatures exceeding 100°F without compromising performance or dimensional accuracy.

Chemical resistance prevents degradation from cleaning agents used in screen reclaiming, a critical advantage given the frequent exposure to solvents and cleaning chemicals during frame maintenance. Unlike wood frames that deteriorate from repeated wet-dry cycles in Phoenix’s arid climate, aluminum frames show no performance degradation from humidity and temperature extremes common in desert environments.

What Upfront and Long-Term Costs Are Associated with Aluminum Frames?

Aluminum frames require higher initial investment but deliver superior long-term value through reduced operating costs. Estimated annual maintenance costs for aluminum frames range from $50-$100, significantly lower than wood frame maintenance expenses. Lower long-term costs result from reduced replacement frequency and associated downtime that impacts production schedules.

The extended lifespan of aluminum frames provides better return on investment despite higher initial price. While wood frames may cost $27-$40 initially, aluminum frames lasting 40+ years with re-stretching capability ultimately cost less per year of service than wood frames requiring replacement every 20-30 years.

This cost analysis becomes particularly compelling for Phoenix operations where environmental conditions accelerate wood frame deterioration, shortening replacement cycles and increasing total ownership costs. Aluminum frames provide predictable, stable performance that supports consistent production planning and budgeting.

How Does the Choice Between Wood and Aluminum Screen Frames Impact Screen Printing Results?

Frame material directly influences the ability to maintain proper mesh tension for quality prints. Aluminum’s superior rigidity enables consistent results across production runs, while wood’s variability in response to environmental conditions creates unpredictable print outcomes.

The tensile yield strength of aluminum (6063-T5) reaches 145 MPa (21,000 psi), compared to variable strength in wood depending on type and grain direction. This fundamental difference in material properties translates directly into printing performance variations that affect every aspect of production quality.

This section examines how frame material choice impacts ink deposition, detail retention, registration accuracy, and performance under Phoenix’s challenging environmental conditions.

Does Frame Material Influence Ink Deposition and Detail Retention?

Frame material influences ink deposition and detail retention through its ability to maintain consistent mesh tension throughout production runs. Higher tension capability of aluminum frames improves ink transfer control by providing stable screen-to-substrate contact pressure.

Stable aluminum frames maintain detail resolution throughout print runs because they resist the dimensional changes that cause progressive tension loss. Wood frame tension loss leads to progressive degradation in print sharpness as moisture and temperature fluctuations cause the frame to flex and lose its ability to hold proper mesh tension.

Low screen tension from frame instability leads to poor ink transfer, loss of detail, and misregistration issues that compound over time. The superior strength and rigidity of aluminum frames allow them to hold significantly higher mesh tension than wood frames, enabling finer detail reproduction and better ink control.

Can Frame Choice Affect Registration and Consistency in Production?

Frame choice affects registration and consistency in production through dimensional stability under varying environmental conditions. Aluminum frames’ dimensional stability ensures accurate multi-color registration because they maintain their shape and tension uniformly across temperature and humidity changes.

Wood frames’ tendency to warp creates registration challenges in complex designs, particularly in multi-color applications where precise alignment is critical. The coefficient of thermal expansion for aluminum is 23.4 µm/m-°C versus 20-70 x 10⁻⁶ /°C for wood depending on moisture and grain direction, making aluminum’s dimensional response more predictable.

Consistent tension in aluminum frames reduces print defects and waste by eliminating the variability that causes screen positioning errors and uneven ink deposits during production runs.

How Do Local Humidity and Temperature in Phoenix Impact Frame Performance?

Local humidity and temperature in Phoenix impact frame performance differently for wood and aluminum materials despite the city’s low ambient humidity levels. Screen reclaiming process introduces significant water and chemicals to frames despite low ambient humidity, creating conditions that challenge wood frame stability.

Rapid drying in hot, arid air after reclaiming accelerates wood frame deterioration through rapid moisture loss that causes warping and cracking. Phoenix experiences average summer temperatures of 95°F with over 100 days exceeding 100°F annually, while relative humidity drops below 20% during summer months.

Aluminum frames show no performance degradation from Phoenix’s humidity and temperature extremes because their chemical resistance prevents degradation from cleaning agents used in screen reclaiming, and their thermal properties remain stable at temperatures exceeding 100°F.

The extreme heat reduces wood strength, increasing susceptibility to deflection under tension, while aluminum’s predictable thermal expansion maintains structural integrity without compromising frame performance. Wood frames rarely return to original shape if bent while wet during screen reclaiming in Phoenix’s challenging climate conditions.

What Do Local Phoenix Screen Printing Experts Recommend for Screen Frame Materials?

Local Phoenix screen printing experts consistently recommend aluminum frames for professional operations. Phoenix hosts a thriving screen printing industry serving diverse clientele from local businesses to major entertainment brands. Industry literature indicates strong professional preference for aluminum frames specifically in Phoenix’s challenging desert climate, where extreme heat and low humidity create harsh conditions for frame materials.

The scale of operations and quality commitments of major Phoenix printers strongly suggest widespread aluminum frame adoption. Professional facilities handling high-volume work prioritize reliability and precision that aluminum provides, particularly when serving clients with exacting standards.

Are There Regional Trends in Frame Material Choice for Phoenix Studios?

Professional Phoenix screen printers prioritize reliability and precision that aluminum provides over cost savings from wood alternatives. Desert climate conditions amplify wood frame weaknesses, driving aluminum adoption across the region’s commercial printing facilities.

The extreme temperature swings and arid conditions in Phoenix create an environment where wood frames deteriorate rapidly, making aluminum the logical choice for studios focused on consistent, high-quality output.

How Does Thrive Screen Printing Approach the Wood vs Aluminum Decision?

Thrive Screen Printing operates a 40,000-square-foot facility equipped with high-volume M&R automatic presses designed for precision production. The company handles large-scale orders for major clients like the Grammy Awards, requiring unwavering reliability and precision that only aluminum frames can deliver consistently.

Thrive’s emphasis on quality and consistency in serving high-profile entertainment industry clients strongly indicates aluminum frame usage throughout their operation. The investment in professional-grade equipment and commitment to meeting demanding deadlines necessitates frame materials that maintain stability under Phoenix’s harsh conditions.

The decision between frame materials connects directly to production reliability, making aluminum the clear choice for operations focused on professional excellence and client satisfaction.

How Should You Decide Between Wood and Aluminum Screen Frames for Your Phoenix Screen Printing Projects?

The decision between wood and aluminum screen frames depends on three critical factors: your quality requirements, production volume, and long-term business goals. Investment in high-quality aluminum frames leads to improved print quality and reduced downtime, making them essential for professional operations in Phoenix’s demanding environment.

Phoenix’s challenging environmental conditions create unique stresses that make aluminum the optimal material for professional results. With over 100 days exceeding 100°F annually and humidity dropping below 20% during summer months, wood frames experience accelerated deterioration that compromises print consistency. Aluminum frames maintain dimensional stability regardless of these extreme conditions, ensuring reliable performance when your business depends on quality output.

Cost-benefit analysis should consider long-term value rather than initial purchase price. While aluminum frames cost upwards of $42.50 compared to wood frames at $27-$40 for a 23″x31″ size, aluminum’s 40+ year lifespan and annual maintenance costs of $50-$100 significantly outperform wood’s 20-30 year lifespan and $100-$300 annual maintenance requirements. This analysis examines consultation resources and key decision factors for Phoenix screen printers.

Can Thrive Screen Printing Help You Select the Ideal Screen Frame Material?

Thrive Screen Printing can assess your specific production needs through professional consultation that evaluates budget constraints alongside quality requirements. Operating a 40,000-square-foot facility with high-volume M&R automatic presses, Thrive handles large-scale orders for major clients like the Grammy’s, requiring the reliability and precision that aluminum frames provide.

Experienced Phoenix printers can demonstrate performance differences between frame materials through direct testing and real-world examples. Professional consultation reveals how aluminum’s tensile yield strength of 145 MPa (21,000 psi) compared to wood’s variable strength translates into tangible benefits for your specific printing applications, helping you make an informed investment decision.

What Are the Most Important Takeaways About Wood vs Aluminum Screen Frames in Phoenix?

Aluminum frames provide superior strength, stability, and resistance to Phoenix’s extreme heat and low humidity conditions that cause wood frames to warp, crack, and lose tension. With aluminum’s coefficient of thermal expansion at 23.4 µm/m-°C remaining predictable and uniform, frames maintain structural integrity despite temperature fluctuations exceeding 100°F.

Long-term cost effectiveness of aluminum outweighs the higher initial investment through reduced replacement frequency, lower maintenance costs, and eliminated downtime from frame failures. Wood frames pose significant risk to print quality and consistency in professional operations, as tension loss from environmental changes creates registration challenges and progressive degradation in print sharpness.

Aluminum’s infinite recyclability requiring only 5% of the energy needed for new production, combined with its 40+ year durability, contributes to lower environmental impact over time compared to frequently replaced wood frames.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.