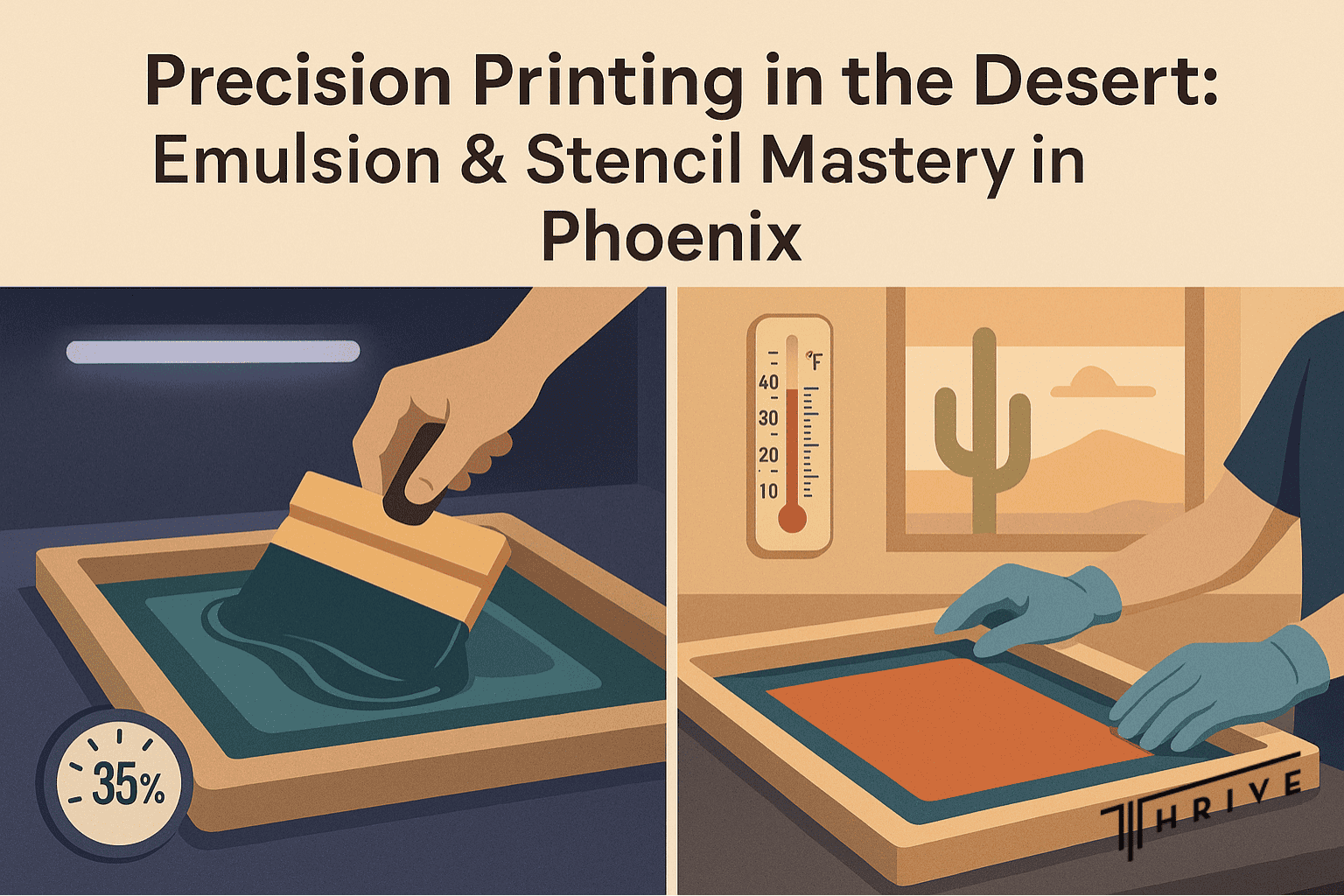

If you’re researching photo emulsion and stencil methods for screen printing in Phoenix, you’re likely either starting a screen printing venture, looking to improve your current techniques, or searching for a professional service that understands the unique challenges of printing in the desert. We understand that navigating the technical aspects of screen printing while dealing with Phoenix’s extreme climate can feel overwhelming. You’re in the right place – we’ll break down everything you need to know about these essential screen printing techniques and how they work specifically in Phoenix’s challenging environment.

Photo emulsion and stencil methods in Phoenix screen printing are light-sensitive coating processes that create precise stencils on mesh screens, enabling high-quality prints despite the city’s extreme heat (111 days above 100°F annually) and low humidity (as low as 17% in June), which require special climate adaptations and material considerations.

TL;DR Summary:

• Photo emulsion techniques use three main types of light-sensitive materials (Dual Cure, Pure Photopolymer, and Diazo), each with specific advantages for different printing needs and Phoenix’s climate conditions

• The step-by-step application process involves either direct emulsion coating or capillary film methods, with capillary films drying faster in Phoenix’s arid environment

• Common mistakes include exposing screens before complete drying and choosing the wrong emulsion type for Phoenix’s humidity levels, which directly impact stencil quality

• Stencil methods range from hand-cut options to photo emulsion stencils, with capillary films producing sharper prints ideal for halftone work

• Phoenix’s extreme climate requires climate-controlled facilities, humidifiers maintaining 30-40% relative humidity, and special ink storage considerations

• Screen preparation demands proper coating, exposure timing adjusted for local conditions, and adherence to Maricopa County’s VOC regulations (3.3 lbs/gal maximum)

• Design complexity and color requirements interact differently with each method, with capillary films excelling at high-specification printing

• Thrive Screen Printing operates a 40,000 sq ft climate-controlled facility in Phoenix, offering water-based, plastisol, foil, and high-density printing methods for businesses of all sizes

Quick Tip: Always store your emulsions and screens in the coolest part of your workspace – Phoenix’s heat can dramatically accelerate chemical reactions in photo emulsions, so keeping materials on lower shelves away from windows can extend their usable life and improve consistency.

As we explore these methods in detail, you’ll discover how Phoenix’s unique environment shapes every decision in the screen printing process, from material selection to facility design. The techniques we’ll cover form the foundation of the $774.8 million Arizona printing industry, where 893 businesses navigate these same challenges daily.

How Do Photo Emulsion Techniques Work in Screen Printing?

Photo emulsion techniques work by using light-sensitive chemicals to create stencils on mesh screens. The process involves coating a screen with photosensitive emulsion, exposing it to UV light through a positive film, and washing out unexposed areas to form the printing stencil. This photochemical process enables precise image transfer and fine detail reproduction in screen printing applications.

What Materials Are Needed for Photo Emulsion in Screen Printing?

The materials needed for photo emulsion in screen printing include three primary emulsion types and associated supplies. There are three primary types of photo emulsions: Dual Cure (Diazo-Photopolymer), Pure Photopolymer (SBQ), and Diazo emulsions.

Dual Cure emulsions combine diazo and photopolymer technologies with a 4-6 week shelf life after mixing, offering balanced performance for most printing applications. Pure Photopolymer emulsions come ready to use with faster exposure times and extended shelf life, making them ideal for high-volume operations. Diazo emulsions require mixing before use and feature slower exposure times but provide longer stencil life when used with water-based inks.

Cost considerations vary significantly between material types. Capillary films range from $30 to over $200 depending on quality and specifications, while liquid emulsion kits typically cost around $55 for standard applications.

What Are the Step-by-Step Processes for Applying Photo Emulsion?

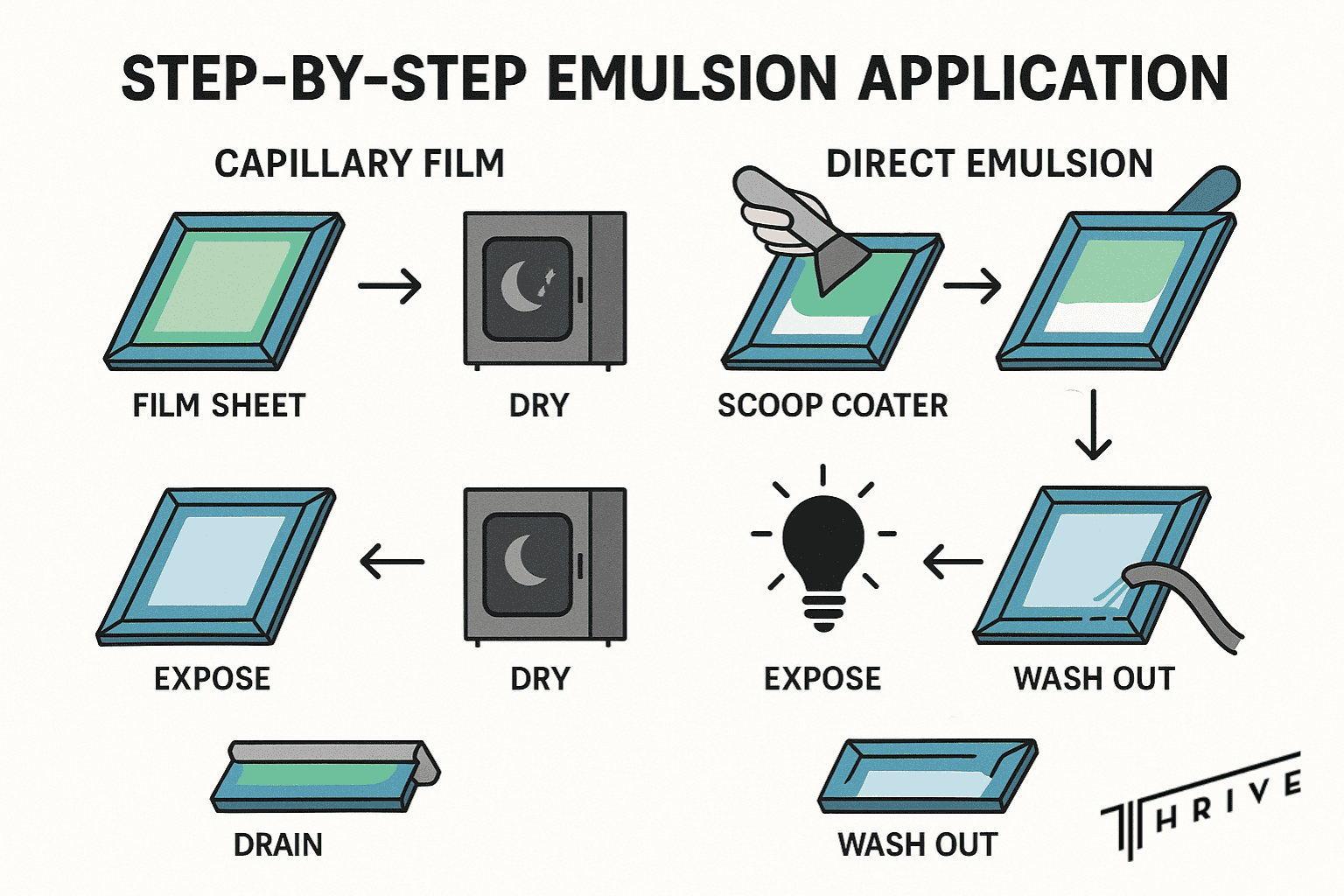

The step-by-step processes for applying photo emulsion involve two primary application methods with distinct characteristics. Direct emulsion involves coating liquid emulsion directly onto the screen, encapsulating mesh from both sides to create a durable stencil foundation.

The capillary film method uses pre-sensitized film of specific thickness applied directly to the screen surface. Capillary films dry faster than direct emulsions, reducing production time and improving workflow efficiency. The direct emulsion method delivers superior durability and remains suited for long print runs requiring extended stencil life.

Application success depends on proper coating technique, controlled drying conditions, and accurate exposure timing to achieve optimal stencil quality.

What Are the Common Mistakes to Avoid With Photo Emulsion?

The common mistakes to avoid with photo emulsion include improper timing, environmental factors, and material selection errors. Exposing screens before they reach complete dryness leads to weak stencils that break down during press operation, resulting in print defects and production delays.

Environmental conditions significantly impact emulsion performance. Diazo and dual-cure emulsions expose slower in high humidity conditions, while photopolymer emulsions expose faster under identical circumstances. Understanding these variables prevents exposure timing errors that compromise stencil integrity.

Material selection requires careful consideration of specific project requirements. According to Robb Cummings from ScreenPrinting.com, “There’s no single ‘best’ emulsion. The right emulsion depends on your experience level, exposure setup, ink type, and darkroom conditions.” This expertise-based approach ensures optimal results for each printing application.

Proper material handling, controlled exposure conditions, and systematic quality checks form the foundation for successful photo emulsion techniques in professional screen printing operations.

What Stencil Methods Are Used in Phoenix Screen Printing?

Phoenix screen printers employ three primary stencil methods: hand-cut stencils, direct photo emulsion, and capillary film stencils. Each method offers distinct advantages for different printing applications, from simple designs to complex halftone work. Understanding these techniques helps businesses select the optimal approach for their specific printing needs and quality requirements.

How Do Hand-Cut Stencils Differ From Photo Emulsion Stencils?

Hand-cut stencils differ from photo emulsion stencils in material composition, application method, and design complexity capabilities. Hand-cut stencils use physical materials like knife-cut film or paper adhered directly to the screen mesh. Photo emulsion stencils utilize light-sensitive chemicals that harden when exposed to UV light, creating precise image reproduction through photographic processes.

Hand-cut stencils excel for:

- Simple geometric shapes and text

- Single-color designs without gradients

- Quick turnaround projects

- Bold, graphic elements with clean edges

Photo emulsion stencils provide:

- Fine detail reproduction down to halftone dots

- Complex multi-color registration accuracy

- Photographic image transfer capabilities

- Consistent thickness across the entire design area

The choice between methods depends on design complexity, required detail level, and production volume for Phoenix printing projects.

What Are the Pros and Cons of Different Stencil Methods?

The pros and cons of different stencil methods vary significantly based on application requirements and production constraints. Direct emulsion provides better adhesion and durability for very long print runs. However, achieving smooth surface with direct emulsion is challenging without automated equipment.

Direct Emulsion Benefits:

- Superior durability for extended print runs

- Strong mesh adhesion prevents stencil breakdown

- Cost-effective for high-volume production

- Compatible with all ink types

Direct Emulsion Limitations:

- Manual coating creates surface inconsistencies

- Requires skilled application technique

- Longer drying times in Phoenix humidity

- More difficult washout process

Capillary film offers perfectly smooth surface leading to sharper prints and excellent detail. Capillary films are easier to use than direct emulsions, making them ideal for detailed work. However, capillary films may be less durable than direct emulsion for very long print runs.

Capillary Film Advantages:

- Consistent thickness across entire stencil

- Superior fine detail reproduction

- Simplified application process

- Faster drying times

Understanding these trade-offs helps Phoenix printers select the most appropriate method for each project’s specific requirements.

How Does the Choice of Stencil Affect Print Quality?

The choice of stencil directly affects print quality through detail reproduction, ink deposit control, and edge definition consistency. Capillary films produce sharper prints with finer detail and are best for halftone stencils, delivering superior performance for complex designs requiring precise dot reproduction.

Direct emulsions can be more challenging to coat smoothly, affecting print sharpness due to surface irregularities that impact ink flow. Manual coating techniques often create thickness variations that result in uneven ink deposits across the design area.

High-quality dual-cure direct emulsions can produce excellent fine detail when properly applied with consistent coating techniques. These emulsions combine the durability benefits of direct application with improved resolution capabilities for detailed work.

Print Quality Factors by Stencil Type:

| Stencil Method | Detail Level | Edge Sharpness | Consistency | Best Application |

| Hand-cut | Low-Medium | Excellent | Good | Bold graphics |

| Direct Emulsion | Medium-High | Good | Variable | Long runs |

| Capillary Film | High | Excellent | Excellent | Halftones |

Phoenix’s dry climate actually benefits stencil consistency by promoting even drying, though temperature control remains essential for optimal results across all methods.

How Do Phoenix’s Climate and Environment Impact Emulsion and Stencil Methods?

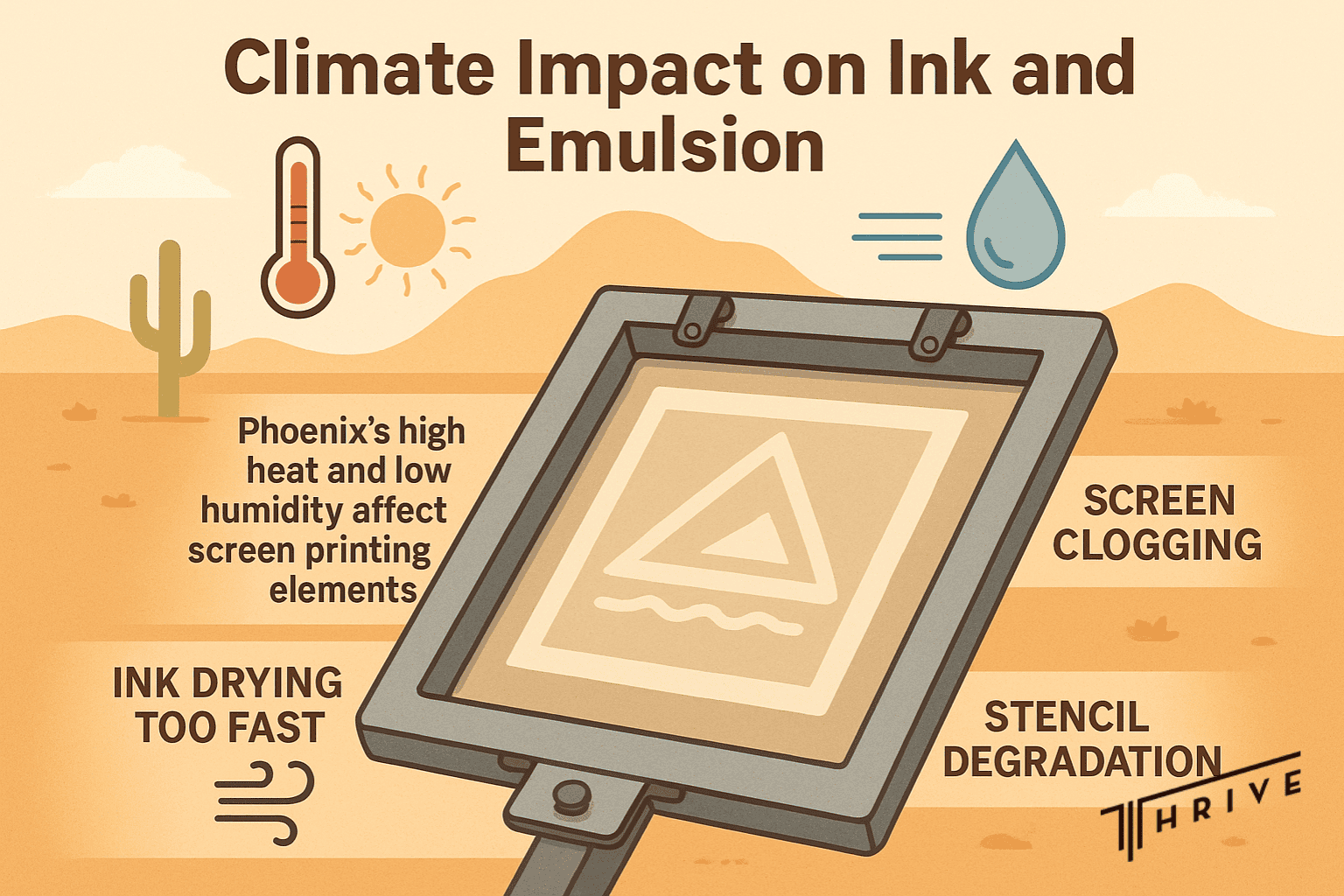

Phoenix’s extreme desert climate significantly impacts photo emulsion and stencil methods in screen printing. The city’s intense heat and low humidity create unique challenges that require specialized techniques and equipment adaptations for successful screen printing operations.

This section covers essential heat-related considerations and practical prevention strategies for maintaining quality stencil production in Arizona’s demanding climate conditions.

What Special Considerations Are Needed for Screen Printing in Phoenix’s Heat?

Special considerations for screen printing in Phoenix’s heat include temperature control, humidity management, ink storage protocols, and facility climate conditioning. Phoenix experiences 111 days annually above 100°F with July averaging 106°F highs, while humidity drops as low as 17% in June.

High temperatures create several operational challenges:

- Ink viscosity changes: High temperatures decrease plastisol ink viscosity, causing over-inking and inconsistent coverage

- Rapid evaporation: Water-based inks evaporate quickly in Phoenix’s low humidity and high heat, causing screen clogging and premature drying

- Storage requirements: Both plastisol and water-based inks require air-conditioned storage in Phoenix to maintain proper consistency

- Facility demands: Operating in climate-controlled facilities is essential for consistent results and product quality

The extreme temperature fluctuations between indoor and outdoor environments can also affect screen tension and emulsion stability during transport and setup.

How Can Artists Prevent Issues Caused by Local Weather When Creating Stencils?

Artists can prevent weather-related stencil issues through humidity control, ink modification, proper storage practices, and timing adjustments. Effective prevention strategies include maintaining optimal environmental conditions and adapting traditional techniques for desert conditions.

Key prevention methods include:

- Humidity management: Use humidifiers in screen rooms to maintain 30-40% relative humidity for optimal emulsion performance

- Ink modification: Add retarder additives to water-based inks to slow drying process and prevent premature screen clogging

- Strategic storage: Store inks on lower shelves away from direct sunlight and heat sources to maintain stability

- Timing considerations: Phoenix’s dry air accelerates emulsion drying but requires complete drying before exposure

As Kevin Kauth, Chromaline Technical Sales Representative, notes: “If you’re hot and sticky so are your screens!” This highlights the direct relationship between ambient conditions and screen printing performance in Phoenix’s climate.

Additional considerations include scheduling production during cooler morning hours and using rapid-setup techniques to minimize exposure time to extreme conditions.

Phoenix’s unique climate demands specialized approaches to photo emulsion and stencil methods, requiring screen printers to adapt traditional techniques for optimal results in desert conditions.

What Are the Best Practices for Screen Preparation and Cleanup?

Screen preparation and cleanup best practices ensure consistent print quality while maintaining regulatory compliance in Phoenix’s challenging environment. Proper coating, exposure, and washing techniques paired with environmental safety protocols protect both equipment longevity and operational sustainability. These practices become especially critical in Phoenix’s extreme heat, where temperature fluctuations can compromise emulsion stability and accelerate chemical reactions.

How Should Screens Be Coated, Exposed, and Washed Out?

Screen coating requires a controlled environment with stable temperature and humidity levels for optimal emulsion adhesion. Clean screens thoroughly with degreasing agents before applying emulsion in smooth, even strokes using a scoop coater held at a 45-degree angle. Store coated screens horizontally in a dark room at 68-75°F with 30-40% relative humidity to prevent premature curing.

Exposure timing varies by emulsion type and Phoenix’s intense UV conditions. Direct emulsion typically requires 8-12 minute exposures using 5000-watt metal halide lamps, while capillary films need 4-6 minutes due to their consistent thickness. Test exposure times using step wedges to determine optimal settings for each emulsion batch, as Phoenix’s dry air can alter emulsion sensitivity by 15-20% compared to humid climates.

Washout procedures must account for Phoenix’s hard water mineral content, which can leave residue affecting stencil quality. Use filtered or distilled water when possible, maintaining water temperature between 70-80°F for consistent results. Spray patterns should move from center outward, allowing 30-60 seconds for emulsion to soften before gentle agitation removes unexposed areas completely.

Phoenix’s extreme heat accelerates these processes, requiring faster handling and climate-controlled workspaces to prevent premature drying during application.

What Safety and Environmental Steps Are Important During Cleanup?

Maricopa County Rule 337 sets maximum VOC limits at 3.3 lbs/gal (400 g/L), making proper chemical management essential for Phoenix screen printing operations. Water-based inks have lower VOC content, helping businesses comply with regulations while reducing environmental impact compared to traditional plastisol formulations.

Waste disposal procedures must distinguish between material types and curing states. Fully cured plastisol ink can be disposed in local waste streams following standard protocols, while uncured plastisol may be recyclable through specialized programs. Screen cleaning solvents require hazardous waste collection, with many Phoenix facilities using closed-loop reclamation systems to reduce disposal costs.

Personal protective equipment includes chemical-resistant gloves, safety goggles, and adequate ventilation systems to prevent vapor exposure. Phoenix’s high temperatures increase evaporation rates, requiring enhanced ventilation capacity compared to moderate climates. Install exhaust fans rated for chemical vapors and maintain negative pressure in cleaning areas to protect worker safety.

Emergency protocols should include eyewash stations within 10 seconds of chemical storage areas, with shower facilities for skin contact incidents. Store all chemicals in temperature-controlled environments below 85°F to prevent degradation and maintain safety specifications in Phoenix’s extreme heat conditions.

This section prepares readers for understanding how proper screen preparation and cleanup practices directly influence final print quality and design outcomes.

How Do Photo Emulsion and Stencil Methods Influence the Final Print?

Photo emulsion and stencil methods directly determine print sharpness, detail retention, and color vibrancy in screen printing projects. The choice between capillary films and direct emulsions affects everything from halftone reproduction to edge definition, making method selection crucial for achieving professional results.

How Do Design Details and Colors Interact With Different Methods?

Design details and colors interact differently with each stencil method based on surface smoothness and mesh encapsulation properties. Capillary films excel at reproducing fine details because their perfectly smooth surface creates consistent ink transfer across the entire print area.

High-Detail Design Applications:

- Halftone gradients require capillary films for proper dot formation

- Fine line work achieves sharper edges with film-based stencils

- Multi-color registration stays more precise with capillary film’s dimensional stability

- Photographic reproductions maintain better contrast ratios

Direct emulsions can challenge detail reproduction due to coating variations. The liquid application process may create microscopic surface irregularities that affect ink flow patterns. However, high-quality dual-cure direct emulsions produce excellent fine detail when applied with automated coating equipment.

Color density varies between methods due to different mesh encapsulation approaches. Capillary films create uniform ink deposits, while direct emulsions may show slight density variations across larger print areas. This difference becomes most noticeable in solid color blocks and gradient transitions.

How Can Print Quality Be Maximized Using the Right Technique?

Print quality maximization requires matching stencil method to project specifications and production requirements. Start by evaluating design complexity, run length, and required detail level before selecting your approach.

Quality Optimization Strategies:

- Use capillary films for runs under 5,000 pieces requiring fine detail

- Choose direct emulsion for runs exceeding 10,000 pieces needing durability

- Match emulsion type to ink system (water-based inks work best with diazo emulsions)

- Maintain consistent coating thickness regardless of method chosen

In Phoenix’s climate, quality maximization includes environmental controls. Phoenix’s 17% humidity in June can cause rapid emulsion drying, potentially creating uneven coatings. Use humidifiers to maintain 30-40% relative humidity in coating areas for consistent results.

Exposure timing affects final quality significantly. Pure photopolymer emulsions expose faster in Phoenix’s intense UV environment, requiring precise timing adjustments. Dual-cure emulsions provide more forgiving exposure windows but need complete drying before exposure to prevent stencil breakdown.

The combination of proper method selection, environmental control, and precise execution ensures maximum print quality for Phoenix screen printing projects. This foundation leads directly into understanding when specific methods offer the greatest advantages for different project types.

When Should You Choose One Screen Printing Method Over Another?

What Factors Should You Consider Before Selecting a Stencil Technique?

The factors for selecting a stencil technique include cost analysis, print run length, detail requirements, and production environment. Your total cost calculation should include materials, labor time, and failure rates rather than just upfront material prices. An expensive capillary film might end up costing less than an inexpensive direct emulsion when you add up all the factors involved in making a quality stencil, according to Mick Orr from Chromaline.

Key factors to evaluate include:

- Print run length – Direct emulsion provides better durability for very long runs exceeding 10,000 impressions

- Detail requirements – Capillary films excel at halftone work and fine detail reproduction

- Production speed – Capillary films dry faster and reduce setup time

- Environmental conditions – Phoenix’s low humidity affects drying rates for both methods

- Operator skill level – Direct emulsions require more coating expertise for smooth application

Cost analysis should factor material prices, labor hours, remake rates, and equipment needs. Capillary films range from $30 to over $200 while liquid emulsion kits cost around $55, but total project cost depends on successful stencil creation rates.

The next section explores how businesses can apply these factors to make informed decisions for their specific printing needs.

How Can Businesses or Artists Decide on the Best Approach for Their Needs?

Businesses and artists should match stencil methods to their production volume, quality standards, and operational capabilities. Small shops with limited coating experience benefit from capillary films’ consistency, while high-volume operations may justify direct emulsion’s durability advantages despite higher skill requirements.

Decision framework by business type:

- Startup operations – Begin with capillary films for reliable results and faster learning curve

- High-volume shops – Invest in direct emulsion coating equipment and training for cost-per-impression savings

- Detail-focused businesses – Choose capillary films for halftone and fine-line work

- Phoenix-based operations – Account for 17% humidity in June affecting drying and exposure times

Quality requirements should drive method selection. Capillary films produce sharper prints with excellent detail reproduction, making them ideal for intricate designs. Direct emulsions work well for bold graphics and text when properly applied but require automated coating equipment for consistent smooth surfaces.

Production environment factors include available space, climate control, and operator training. Phoenix’s extreme heat requires air-conditioned facilities for consistent results with either method. Water-based emulsions expose faster in low humidity while maintaining longer stencil life than plastisol-optimized formulations.

This analysis helps businesses choose methods that align with their quality goals, production volume, and operational constraints while maximizing profitability in Phoenix’s unique climate conditions.

How Can Thrive Screen Printing in Phoenix Help With Photo Emulsion and Stencil Methods?

Thrive Screen Printing offers comprehensive photo emulsion and stencil services from their 40,000 square foot Phoenix facility. Their expertise spans multiple printing methods and client scales, making them a strategic partner for businesses navigating Arizona’s unique printing environment. The following sections detail their specific capabilities and the broader industry context.

What Services and Expertise Does Thrive Screen Printing Offer for Stencil and Emulsion Requests?

Thrive Screen Printing provides specialized photo emulsion and stencil services from a 40,000 square foot facility in Phoenix. The company offers water-based, plastisol, foil, and high-density printing methods tailored to Arizona’s climate challenges. Their client base spans small businesses to large global brands, demonstrating scalable expertise across project complexities.

The facility’s size enables automated emulsion coating equipment, addressing the smoothness challenges that plague manual direct emulsion applications. Their water-based ink capabilities prove especially valuable in Phoenix’s low humidity environment, where standard formulations require careful modification. Thrive’s nationally recognized status reflects their mastery of climate-controlled processes essential for consistent emulsion curing in extreme heat conditions.

This comprehensive service range positions Thrive as a full-spectrum solution for photo emulsion projects requiring both technical precision and environmental adaptation.

What Are the Key Takeaways About Photo Emulsion and Stencil Methods in Phoenix Screen Printing We Covered?

The Arizona printing industry represents a $774.8 million market in 2025 with 893 businesses, indicating robust demand for photo emulsion and stencil services. The national custom screen printing market reached $9.2 billion in 2024, providing context for local opportunities and competitive landscape.

Equipment investments for photo emulsion operations range from starter kits costing a few hundred dollars to automated machinery exceeding $100,000. Recent innovations include new water-based emulsions with improved wash resistance, addressing traditional durability concerns. 2024 industry trends emphasize AI integration in design processes and growing demand for sustainable printing practices.

These market conditions create opportunities for businesses like Thrive Screen Printing to leverage their climate-adapted expertise and comprehensive service offerings. The combination of strong market fundamentals, technological advancement, and sustainability focus supports continued growth in Phoenix’s screen printing sector.

The industry’s evolution toward environmentally conscious practices aligns with Arizona’s environmental regulations and positions photo emulsion specialists for long-term success.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.