If you’re exploring professional screen printing options for photographic designs, complex artwork, or multi-colored projects in Phoenix, you’re likely weighing the benefits of CMYK four-color process printing. This method offers unique advantages for certain applications, but Phoenix’s desert climate adds specific considerations that directly impact print quality and durability. Understanding how CMYK printing works—and when it’s the right choice—helps ensure your investment delivers the vibrant, long-lasting results you expect.

CMYK four-color process screen printing is a method that uses four transparent ink colors (Cyan, Magenta, Yellow, and Black) overlapped through fine halftone screens to create thousands of color possibilities from just four inks.

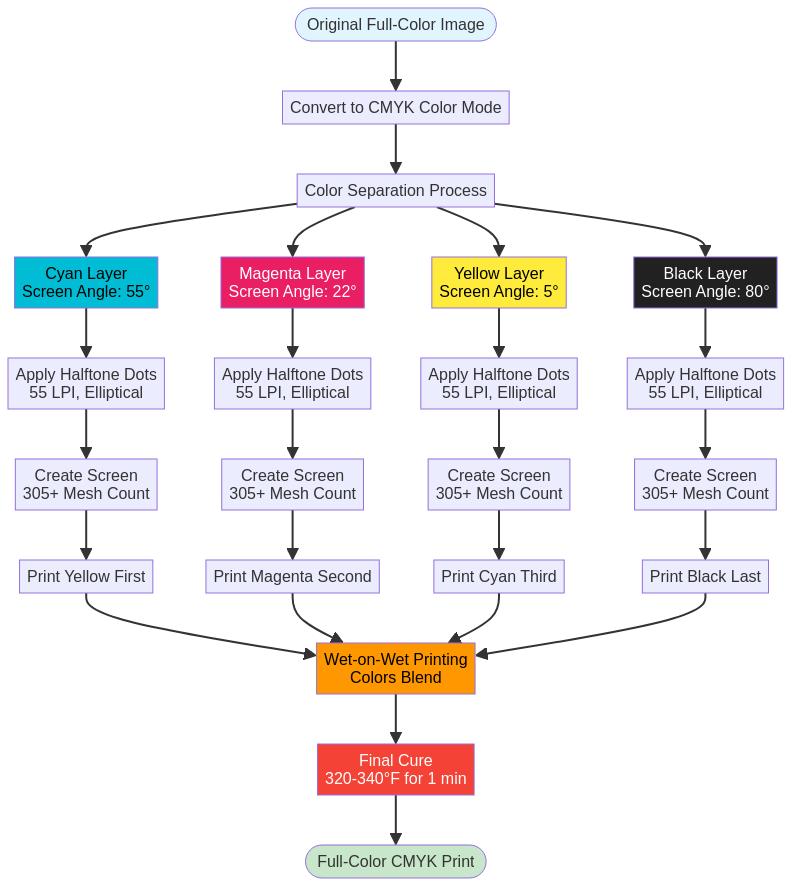

According to Hanzel Ltd., 2025: this process applies inks at specific angles (Yellow: 5°, Magenta: 22°, Cyan: 55°, Black: 80°) to avoid moiré patterns while enabling photographic reproduction. As James Weinberg, graphic design artist, explains: “Process colors are best for photographic reproduction, or something that has a lot of shading and nuance in it.”

This introduction covers how CMYK differs from spot color through transparent ink layering, why it excels at photographic images with smooth gradients, and what limitations challenge printers requiring 305+ mesh counts. You’ll discover which materials suit four-color process best, particularly light-colored tight-weave fabrics, and how Phoenix’s 111 days above 100°F affect ink performance.

We’ll explore why businesses choose CMYK for complex designs exceeding 3-4 colors, what local companies like Thrive Screen Printing offer with 40,000 square foot facilities, and how proper climate control ensures quality.

One practical tip: always convert artwork to CMYK color mode from the start—not RGB—to preview accurate color reproduction before printing. This comprehensive guide equips you with the technical knowledge and local insights needed to make informed decisions about CMYK screen printing in Phoenix’s unique environment.

How Does the CMYK Four-Color Process Differ From Other Screen Printing Methods?

The CMYK four-color process uses four transparent ink colors (Cyan, Magenta, Yellow, Black) overlapped to create thousands of colors, while spot color printing uses premixed solid inks for each specific color. This fundamental difference in ink application creates distinct advantages and limitations for each method.

CMYK applies inks through fine halftone screens with dots positioned at specific angles: Yellow at 5°, Magenta at 22°, Cyan at 55°, and Black at 80°. This precise angular arrangement prevents moiré patterns that can distort image quality. The process requires four separate screens minimum versus one screen per spot color, using wet-on-wet application without flashing between CMYK colors to enable proper color blending.

Spot color printing relies on the PANTONE MATCHING SYSTEM with 18 basic colors and 2,390 PANTONE PLUS Colors available. Over 50% of spot color shades fall outside the CMYK color spectrum range, making spot colors print cleaner and brighter for specific hues. The CMYK printing sequence follows Yellow → Magenta → Cyan → Black to prevent darker inks from overpowering lighter ones, while manual CMYK printing demands expert-level consistency with every squeegee stroke maintaining identical angle, speed, and pressure.

The choice between these methods depends on your project’s color complexity, budget constraints, and quality requirements. CMYK excels at reproducing photographic images and complex color gradients, while spot color delivers precise brand color matching for simpler designs.

What Are the Key Advantages of Using the Four-Color Process?

The four-color process reproduces a wide spectrum of colors from just four inks, creating thousands of color possibilities through strategic ink layering. This method captures photographic images with intricate details and realistic output maintaining the same fidelity as original artwork.

CMYK excels at smooth gradients, rich color transitions, and nuanced shading that spot color cannot achieve. The process proves more cost-effective than spot color for projects requiring multiple colors, saving money by limiting printing to four plates regardless of final color count. Color interactions create vibrant blues and purples through Cyan + Magenta combinations, while rich reds emerge from Magenta + Yellow blending.

Key benefits include:

- Precise color representations ideal for lifelike imagery and detailed designs

- Capability to handle extremely complex colored images, paintings, and decorative elements without extra plates

- Industry standard compatibility for branding materials, brochures, documents, and packaging

- Accurate capture of subtle variations including skin tones and landscape depth

The four-color process delivers professional-quality results for Phoenix businesses requiring photographic reproduction or multi-color designs exceeding simple spot color applications.

What Are the Limitations or Challenges of CMYK Screen Printing?

CMYK screen printing cannot match certain bright or neon colors that fall outside the CMYK gamut, particularly metallic and fluorescent shades. The process requires meticulous color management and skilled execution with thorough understanding of color theory to achieve consistent results.

Technical challenges include higher initial setup costs versus spot color applications due to four separate screens requirement and demanding flawless registration across all screens with precise alignment critical for quality output. The quality of color conversion from spot to CMYK proves very subjective with unpredictable results depending on operator skill.

Specific technical requirements include:

- Mesh count must be 305 (120T) or higher to capture fine halftone dots

- Professional RIP software (AccuRIP or Separation Studio) required for accurate separations

- Manual printing only suitable for small runs with expert printers—automatic press strongly recommended

- Dot density must stay between 15% to 85% to avoid loss or muddiness from dot gain

- One stroke per color only with no double-passes permitted, requiring consistent execution

These limitations make CMYK printing more complex than spot color methods, requiring specialized equipment and expertise that Phoenix’s extreme climate conditions can further complicate.

When Should You Choose CMYK Over Spot Color Printing?

Choose CMYK for photographic reproduction or designs with extensive shading and nuance that require smooth color transitions. Select CMYK when printing extremely detailed artwork with gradients and continuous tones, or for full-color designs requiring more than 3-4 distinct colors to achieve cost savings.

CMYK works best for images with realistic depictions, complex colored imagery, and projects combining multiple photographic elements. Use this method for branding materials requiring photographic backgrounds or artistic designs with flowing color transitions.

Conversely, opt for spot color in these situations:

- Corporate logos requiring exact PANTONE color matching

- T-shirts and screen printing graphics needing isolated, specific colors

- One, two, or three-color jobs where exact color matching is critical

- Bold, vibrant colors outside CMYK gamut like metallics or neons

Many Phoenix businesses combine both methods when needed, using four-color process for photographic elements plus PANTONE spot color for brand logos requiring precise color matching. This hybrid approach delivers the photographic quality of CMYK while maintaining brand color accuracy for corporate identity elements.

The decision ultimately depends on your design complexity, color accuracy requirements, budget constraints, and the specific visual goals of your Phoenix-based project.

What Materials and Apparel Are Most Suitable for CMYK Four-Color Screen Printing?

Materials and apparel choice directly impacts CMYK four-color screen printing quality and vibrancy. Light-colored garments with white or natural cotton backgrounds deliver optimal results with translucent CMYK inks, while tight weave fabrics preserve essential halftone detail. Cotton garments retain more moisture than synthetic materials, requiring longer drying times in Phoenix’s climate. Material selection significantly affects color vibrancy, ink absorption, and final print crispness.

The following sections examine specific fabric requirements, light versus dark material performance, and artwork preparation techniques for achieving professional CMYK results.

Are Certain Fabrics or Garments Better for This Printing Process?

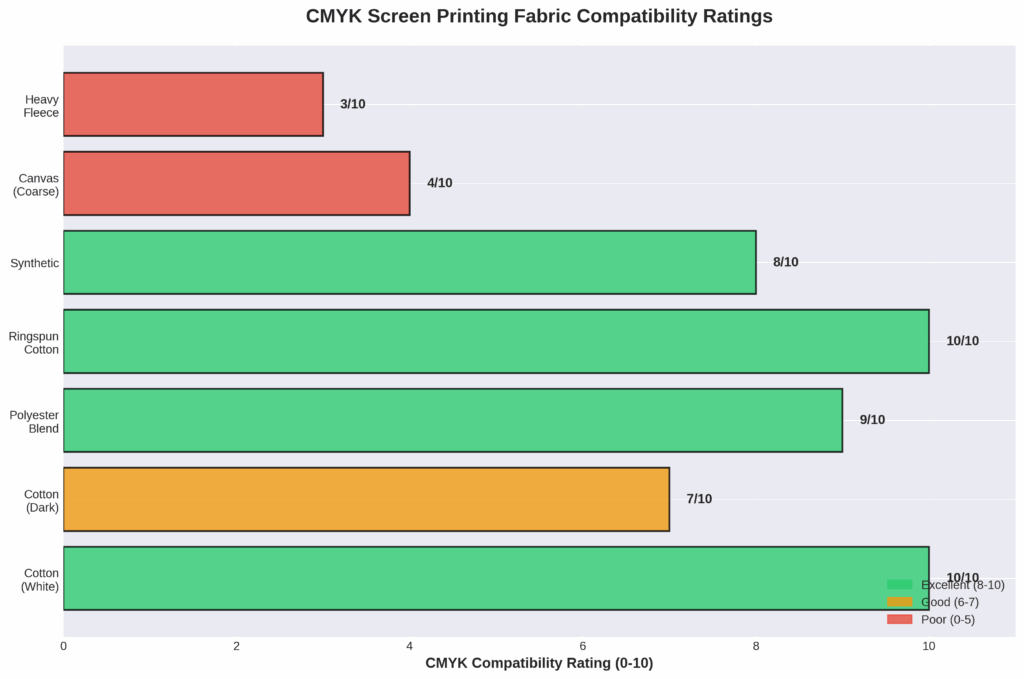

Certain fabrics significantly outperform others for CMYK four-color screen printing quality. Ringspun cotton and polyester blends with tight weaves preserve halftone dot clarity best, enabling intricate details and sharp reproduction. White 100% cotton provides the optimal surface for translucent CMYK ink layers to build clean, vibrant tones.

Fabric Performance Comparison:

| Fabric Type | Weave Quality | Halftone Detail | Drying Time | Color Vibrancy |

| Ringspun Cotton | Tight weave | Excellent clarity | Longer retention | High vibrancy |

| Polyester Blends | Fine weave | Sharp details | Faster drying | Good vibrancy |

| White 100% Cotton | Optimal surface | Best translucency | Standard time | Maximum vibrancy |

| Canvas/Heavy Fleece | Coarse weave | Distorted dots | Variable | Poor quality |

Finer weaves deliver intricate details and sharpness, while coarser weaves create textured, vintage appearances. Synthetic materials offer less moisture retention and faster drying than cotton, making them suitable for Phoenix’s humid August period when humidity spikes to 24%.

Does the Process Work Equally Well on Light and Dark Materials?

Light materials significantly outperform dark materials for CMYK printing quality and color reproduction. Dark garments require a white underbase as a fifth screen, adding complexity and registration challenges. The underbase must be flash-cured before CMYK application to prevent color absorption into the dark substrate.

Light vs. Dark Material Requirements:

- Light Materials: Four screens total, direct CMYK application, full color range achievable

- Dark Materials: Five screens minimum, white underbase required, reduced vibrancy potential

- Registration Precision: Dark materials demand precise alignment across five screens versus four

- Color Range: White and natural cotton enable translucent inks to achieve complete color spectrum

Dark substrates may show color shifts and reduced vibrancy even with proper underbase application. Careful underbase control remains essential to prevent muddy colors or loss of halftone detail in the final print.

How Should You Prepare Artwork or Designs for Best Results?

Artwork preparation determines CMYK four-color screen printing success and final output quality. Minimum 300 DPI resolution is required, with oversized designs preferred to maintain detail after halftone conversion. Convert artwork to CMYK color mode from the start, as RGB color mode is designed for screens only and produces unpredictable print results.

Technical Artwork Requirements:

- Resolution: 300 DPI minimum, final output at 200 DPI for screen printing

- Color Mode: CMYK throughout the design process, never RGB

- Halftone Density: 15% to 85% range to avoid dot loss or muddiness

- Line Count: 55 LPI (26.6 lines per cm) balancing detail with printability

- Dot Shapes: Elliptical shapes work best with mesh grid structures

Professional Software Settings:

- Use AccuRIP or Separation Studio for accurate color separation

- Set proper screen angles: Yellow 5°, Magenta 22°, Cyan 55°, Black 80°

- Apply Curves and Shadows/Highlights for optimal tonal balance

- Preview CMYK conversion in Adobe Photoshop before final output

This preparation ensures Phoenix’s extreme temperatures and low humidity conditions don’t compromise the precision required for professional CMYK four-color process results.

Why Is Phoenix’s Climate Important When Considering Four-Color Screen Printing?

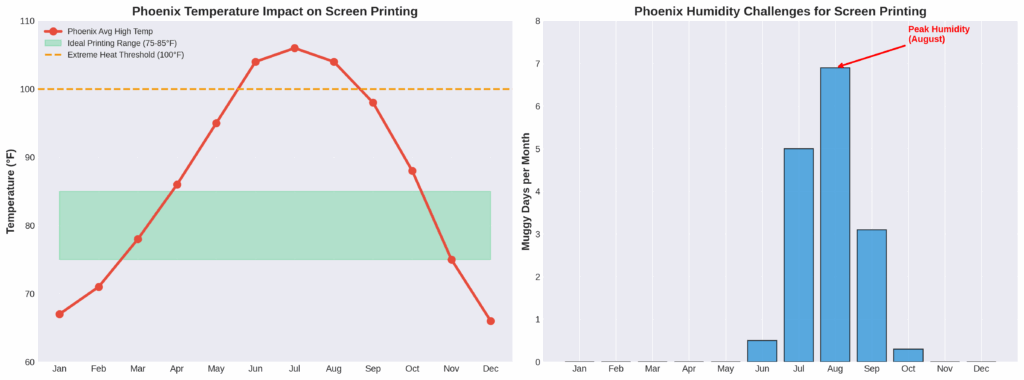

Phoenix’s climate significantly impacts four-color screen printing operations due to extreme temperature variations and unique desert conditions. Phoenix experiences 111 days annually with temperatures above 100°F, creating challenging conditions for ink consistency and equipment performance. The city’s temperature typically ranges from 45°F to 107°F, with the UV Index reaching 10 (very high) and 151 days of very high/extreme UV exposure annually.

The desert environment offers both advantages and challenges for CMYK printing. Phoenix maintains 0% humidity most of the year, creating ideal conditions for ink drying and curing, except during the muggy period from June 30 to September 24. The mostly clear skies (86% clear annually) provide predictable production conditions, though extreme temperatures affect screen printing more prominently than in stable climates.

Does the Desert Environment Affect Ink Performance or Curing?

The desert environment directly affects ink performance through temperature and humidity variations. Plastisol inks increase viscosity in cold weather, requiring shop temperatures above 75°F for optimal consistency. Water-based inks present greater challenges, as they can freeze during cold periods due to high water content and evaporate rapidly during Phoenix’s dry, hot climate.

Excessive heat triggers the ink gelling process between 180°F and 240°F, making inks thicker and harder to work with. Phoenix’s low humidity (0% most of the year) creates excellent conditions for drying and curing but causes rapid water-based ink evaporation on screens. August’s humidity spike to 24% with 6.9 muggy days requires adjusted curing times, as cotton garments need longer drying periods during humid conditions, reaching 212°F before curing begins. Regardless of climate conditions, curing temperature requirements remain constant at 320-340°F for approximately one minute.

Are There Environmental or Regulatory Concerns in Phoenix for Printers?

Phoenix screen printing operations must comply with multiple regulatory requirements at federal, state, and local levels. Arizona requires a business license and sales tax permit for screen printing operations, while OSHA regulations apply, including Material Safety Data Sheets (MSDS) requirements for all chemicals and inks used in production.

EPA regulations for the printing sector include NESHAPs (National Emission Standards for Hazardous Air Pollutants) for paper surface coating, and RCRA hazardous waste regulations apply under NAICS 323 (Printing and Related Support Activities). Screen printers must also verify copyright compliance to avoid infringement when reproducing images and implement hazardous waste management protocols that comply with federal and state requirements. Environmental regulations specific to ink disposal and chemical management in the desert environment require careful attention to prevent contamination in Phoenix’s unique ecosystem.

How Can You Ensure Durable, High-Quality Prints in Local Conditions?

Ensuring high-quality CMYK prints in Phoenix requires strategic adaptation to local climate conditions. Store inks on lower shelves where temperatures remain cooler during Phoenix’s hot season (May 29 to September 20), and keep all inks away from direct sunlight and heat sources that affect consistency. Mix inks before use to restore proper consistency after temperature exposure.

Maintain shop temperatures above 75°F for plastisol inks to prevent viscosity issues, and store water-based inks above-ground in insulated rooms to prevent freezing during winter months. Allow emulsion to dry completely before exposure, checking for tackiness that indicates incomplete curing. According to Thrive Screen Printing, controlling temperature in the printing shop serves as the first determinant of print quality.

High-quality screen printed materials should last 10 years or more with proper care and execution. Optimal production conditions occur from November through April when temperatures range from 66-86°F with 0% humidity, providing the most stable environment for consistent CMYK four-color process printing in Phoenix.

What Do Businesses and Organizations in Phoenix Commonly Print Using CMYK Four-Color Process?

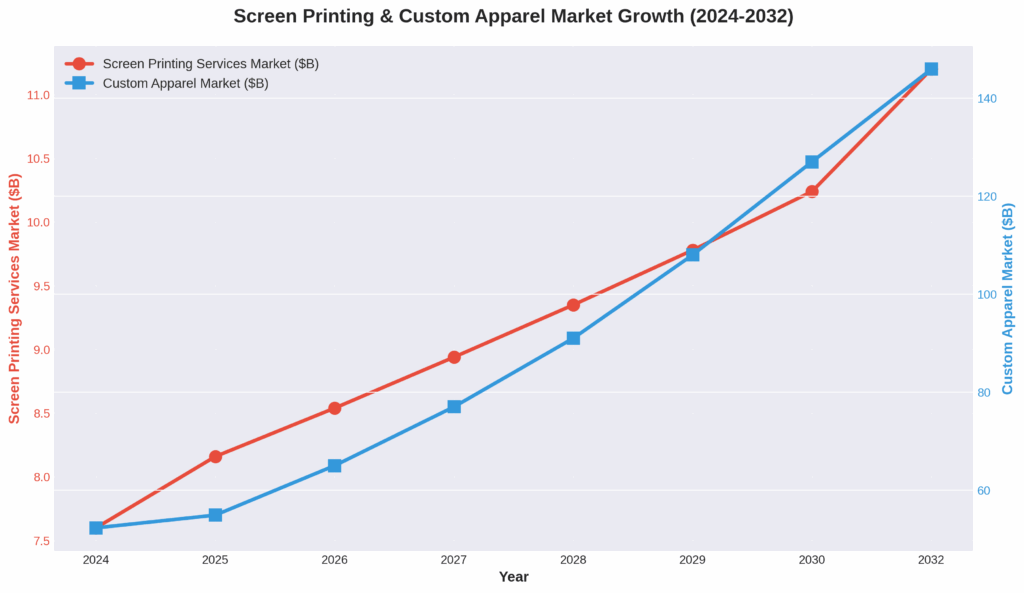

Businesses and organizations in Phoenix commonly print entertainment merchandise, corporate branding materials, educational institution orders, sports team apparel, non-profit promotional items, and private apparel brand products using CMYK four-color process. The entertainment industry leads demand with Grammy’s merchandise and band materials through local printers like Thrive Screen Printing. Corporate clients combine CMYK with spot colors for exact logo reproduction on branding materials.

Educational institutions generate significant volume from small classroom orders to large wholesale bulk orders for schools globally. Sports organizations range from local softball leagues to nationally licensed sportswear requiring complex multi-color designs. Non-profit organizations choose CMYK for cost-effective design and delivery solutions, while private apparel brands scale production through local Phoenix printers serving thousands of customers.

This section explores specific project types and design examples that maximize CMYK’s photographic reproduction capabilities.

Which Types of Projects or Events Is This Printing Process Best Suited For?

CMYK four-color process excels at photographic reproductions requiring realistic output with shading and nuance. The process serves full-color promotional materials for corporate events and marketing campaigns where industry-standard color reproduction matters. Complex artistic designs benefit from CMYK’s smooth gradients and rich color transitions.

Entertainment merchandise featuring detailed artwork or photographic elements relies on CMYK’s ability to capture subtle variations. Custom apparel with intricate designs exceeding 3-4 colors becomes cost-efficient through four-plate printing versus multiple spot colors. Projects requiring vibrant blues, purples, and red spectrum through color interaction maximize CMYK’s cyan-magenta and magenta-yellow combinations.

Project Types Best Suited for CMYK:

- Branding materials, brochures, and documents requiring precise color matching

- Extremely detailed artwork capturing skin tones and facial features

- Corporate event materials combining photographic backgrounds with branded elements

- Marketing campaigns demanding consistent color reproduction across materials

What Are Some Examples of Vibrant, Photographic, or Complex Designs?

Realistic portraits with accurate skin tone reproduction and facial detail represent CMYK’s strongest application. Landscape photography with depth requires subtle color gradations that only four-color process achieves effectively. Fine art reproductions maintain the same fidelity as original paintings through CMYK’s halftone precision.

Band merchandise featuring photographic album artwork or complex graphics demonstrates entertainment industry applications. Sports team designs with detailed mascots, gradients, and multiple color transitions showcase CMYK’s versatility. Wildlife or nature photography requiring smooth color blending captures environmental details through precise dot placement.

Examples of Complex CMYK Applications:

- Abstract designs with flowing gradients and continuous tone effects

- Corporate materials combining photographic backgrounds with branded elements

- Sports team designs with detailed mascots and multiple color transitions

- Wildlife photography requiring smooth color blending and environmental detail

These applications leverage CMYK’s ability to reproduce thousands of colors from four transparent ink layers, making Phoenix businesses choose this process for projects demanding photographic quality and complex color relationships.

What Should You Look For in a Phoenix Screen Printing Company for CMYK Four-Color Process?

A Phoenix screen printing company for CMYK four-color process should offer state-of-the-art facilities, comprehensive in-house capabilities, and proven experience with complex color printing. Key indicators include large-scale operations like Thrive Screen Printing’s 40,000 square foot facility in the heart of Phoenix, complete design and production control systems, and expertise with both water-based and plastisol inks for diverse project requirements.

Essential features include multi-manual checking processes ensuring order consistency, capability to serve clients from small businesses to large-scale global enterprises, and convenient services like free local delivery in the Phoenix-Metro area with hand-delivered options. Same-day turnaround availability for rush custom t-shirt orders demonstrates operational efficiency crucial for CMYK printing success.

The following sections detail specific evaluation criteria for print quality, equipment standards, and capacity assessment to help you select the right Phoenix screen printing partner.

How Can You Evaluate Print Quality and Color Accuracy?

Print quality and color accuracy evaluation begins with requesting samples showing CMYK halftone dot clarity at 305 mesh count or higher. Professional CMYK screen printing requires precise dot reproduction to achieve photographic-quality results and smooth color transitions.

Critical evaluation criteria include:

- Verify use of professional RIP software for accurate color separation

- Check for moiré pattern absence indicating proper screen angle settings (Yellow: 5°, Magenta: 22°, Cyan: 55°, Black: 80°)

- Examine registration accuracy across all four color plates in sample prints

- Review color matching capabilities using calibrated monitors and color profiles

- Assess consistency across multiple print runs of same design

- Verify ISO 12647 compliance for color reproduction requirements

- Request wash testing results demonstrating durability after proper curing at 320-340°F

Professional shops maintain strict quality control with calibrated equipment and documented processes ensuring repeatable results across production runs.

What Questions Should You Ask About Equipment and Experience?

Equipment and experience questions should focus on technical capabilities essential for CMYK printing success. Ask whether they use automatic presses for consistent ink deposit and perfect registration, as manual printing only suits small runs with expert operators.

Essential questions include:

- What mesh counts do you use for CMYK printing (should be 305 or higher)?

- How do you maintain screen tension at 25 Newtons/cm² (±2N) for quality?

- What RIP software do you use for color separation (AccuRIP or Separation Studio preferred)?

- How many years experience with four-color process printing specifically?

- Can you handle both water-based and plastisol CMYK printing?

- What quality control program covers your 20-point checklist areas?

- Do you have climate-controlled production space for Phoenix’s extreme temperatures?

Experience with Phoenix’s unique climate challenges—including 111 days annually above 100°F—requires specialized environmental controls for consistent ink performance and curing results.

Can Local Screen Printers Handle Large or Rush Orders Effectively?

Local screen printers like Thrive Screen Printing demonstrate capacity by fulfilling tens of thousands of individual customer orders weekly with same-day turnaround available for custom t-shirts at multiple Phoenix locations. Companies globally trust Phoenix printers for fast, accurate delivery times supported by the region’s predictable weather patterns.

Capacity indicators include no minimum order requirements enabling project flexibility, bulk discounts through wholesale contract screen printing services, and worldwide shipping capabilities with “printed in USA” designation. According to Thrive, “No matter the project size, we can handle it on time, every time.”

Phoenix’s extended production season and predictable climate provide advantages for consistent CMYK printing schedules, while established facilities offer the infrastructure needed for both small custom orders and large-scale commercial production runs.

How Does Thrive Screen Printing Support CMYK Four-Color Process Screen Printing Needs in Phoenix?

Thrive Screen Printing supports CMYK four-color process screen printing through its comprehensive 40,000 square foot facility at 3050 S 44th St, Phoenix, AZ 85040, combining advanced equipment, experienced leadership, and specialized services for complex color reproduction projects. Founded and led by CEO Robert Fisher, the company brings extensive screen printing industry experience to handle the technical demands of CMYK printing, from precise registration to climate-controlled production environments essential for Phoenix’s extreme temperatures.

The facility houses in-house design capabilities completing thousands of projects annually, offering both water-based and plastisol ink options for different CMYK applications. Thrive’s water-based ink screen printing delivers higher quality and longer-lasting results, particularly important for Phoenix’s dry climate where rapid evaporation affects ink performance. Their specialty printing options include foil, flock, high density, metallic, and gel applications that can complement CMYK processes for enhanced visual impact.

The following sections detail Thrive’s specific services and the key considerations for CMYK four-color process screen printing in Phoenix’s unique desert environment.

What Services Does Thrive Screen Printing Offer for Four-Color Process Projects?

Thrive Screen Printing offers wholesale screen printing services focused on quality, accuracy, consistency, and superior delivery times for CMYK four-color process projects. The company handles custom t-shirt printing with same-day turnaround availability, critical for rush orders requiring complex color reproduction.

Core Services Include:

- Apparel finishing services from press to retail ready

- In-house design help with clear communication of needs and expectations

- Multi-manual checking process ensuring orders consistent “Every. Single. Time”

- Free local delivery in Phoenix-Metro area with hand-delivered options

Thrive prints, finishes, and fulfills tens of thousands of individual customer orders weekly, serving diverse markets including private brands, entertainment, corporate events, bands, sports, education, and non-profits. Their capacity to handle both small businesses and large-scale global enterprise clients makes them suitable for projects ranging from simple promotional items to complex photographic reproductions requiring precise CMYK color matching.

What Are the Key Takeaways About CMYK Four-Color Process Screen Printing in Phoenix?

CMYK four-color process screen printing excels at photographic reproduction but requires 305+ mesh count screens and precise registration across all four color plates to achieve professional results. Phoenix’s extreme desert climate, with 111 days above 100°F annually, demands climate-controlled production spaces to maintain ink consistency and prevent quality issues during the printing process.

Critical Success Factors:

- Light-colored tight-weave fabrics deliver best results; dark garments need white underbase

- Process printing more cost-effective than spot color for designs exceeding 3-4 colors

- Water-based inks evaporate quickly in Phoenix’s dry climate requiring careful management

- Optimal production period November-April with temperatures 66-86°F and 0% humidity

Automatic presses are strongly recommended over manual printing for consistent CMYK quality, as the four-color process requires identical ink deposit and perfect registration that manual methods struggle to maintain. Phoenix’s local market includes established companies like Thrive with 40,000 square foot facilities and global reach, providing the infrastructure necessary for high-volume CMYK production while maintaining the technical precision these complex printing projects demand.