If you’re exploring innovative ways to make your custom apparel stand out in the competitive Phoenix market, you’ve likely encountered the term “overprint screen printing effects.” We understand that choosing the right printing technique can feel overwhelming, especially when you want designs that capture attention while withstanding Arizona’s intense heat. You’re in the right place to discover how overprinting can transform your apparel vision into reality.

Overprint screen printing is a specialized technique where screen printing ink colors are layered so the base color shows through the top color, creating unique visual effects through transparency and color mixing. Unlike traditional knockout methods where each color prints separately without touching, overprinting allows inks to overlap intentionally, producing gradient-like appearances and special effects particularly striking with fluorescent inks. This process requires less precision than standard multi-color registration while delivering compelling results that make custom apparel truly distinctive in Phoenix’s vibrant fashion and promotional landscape.

TL;DR Summary: We’ll explore how overprinting differs from standard techniques through its layering process and reduced precision requirements. You’ll discover achievable visual effects including color mixing, opacity variations, and texture enhancements. We’ll examine which materials work best in Phoenix’s extreme climate, weighing advantages like enhanced print depth against technical challenges. Finally, we’ll guide you through business considerations for Phoenix brands and how Thrive Screen Printing’s expertise can bring your overprint vision to life.

Quick Tip: When planning overprint designs, choose inks with built-in UV resistance to combat Phoenix’s 300+ sunny days annually—this small investment adds years to your apparel’s vibrant appearance.

How Does Overprinting Differ from Other Screen Printing Techniques?

Overprinting differs from other screen printing techniques by layering semi-transparent inks to create color mixing effects, while traditional methods apply opaque colors separately without interaction. This fundamental distinction creates unique visual possibilities and requires different technical approaches.

The upcoming sections explore the basic overprinting process, compare effects with standard methods, and examine why designers choose this technique for custom apparel projects.

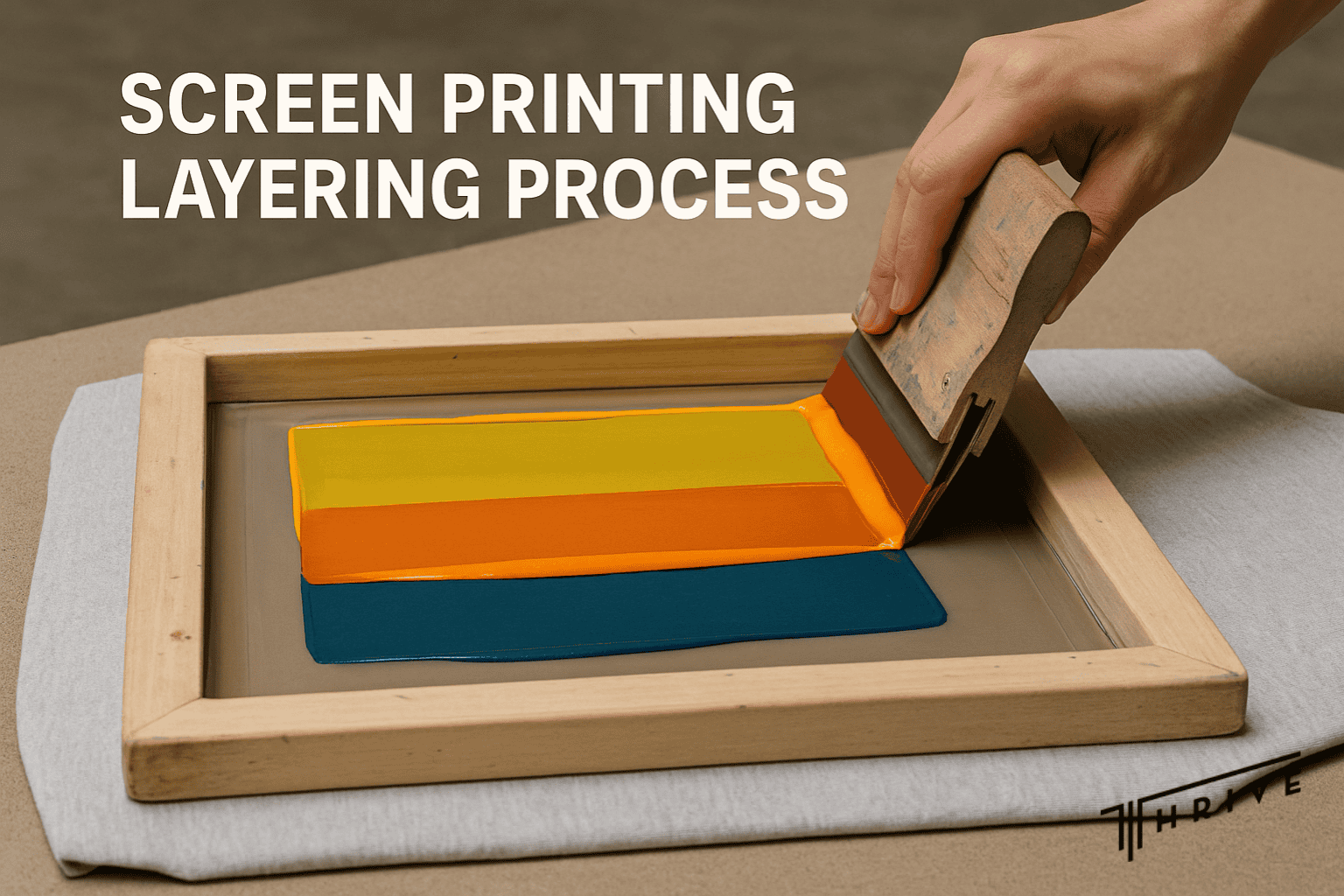

What Is the Basic Process of Overprinting in Screen Printing?

Overprinting is a screen printing technique that layers semi-transparent ink colors where the base color shows through the top color, creating new hues and visual effects. The process uses standard screen printing equipment including a 10×14 screen printing frame, squeegee, and fabric inks specifically formulated for transparency.

Speedball fluorescent inks provide the transparency needed for effective color mixing when layered. These specialized inks allow underlying colors to influence the final appearance, creating dynamic color combinations impossible with opaque alternatives.

The process requires less precision for layer alignment compared to knockout methods, making it more forgiving for manual printing operations while still producing professional results.

How Do Overprinting Effects Compare to Standard Screen Printing Methods?

Overprinting creates overlapping color effects through transparency, while knockout methods apply each color directly to fabric without touching other colors, resulting in solid, uncontaminated hues. The knockout approach produces evenly soaked colors with crisp boundaries between different ink areas.

The white base coat variation represents another standard method that prints the entire design in white ink first, then applies a second color on top for solid appearance. This technique ensures color accuracy on dark fabrics but eliminates transparency effects.

Registration marks serve as alignment guides in knockout methods and require precise positioning, but are less critical for overprinting since slight misalignment can enhance the layered aesthetic rather than detract from it.

Why Do Designers Choose Overprinting for Custom Apparel?

Designers choose overprinting for custom apparel because it creates special effects particularly effective with fluorescent inks, producing unique color mixing results unachievable through standard single-color applications. The technique allows for dynamic color transitions and gradient-like effects within a single print run.

Overprinting requires less precision than knockout methods, which typically need 2-4 color presses for multiple shirt designs. This reduced complexity translates to faster setup times and more forgiving production processes for custom orders.

The unique color mixing capabilities enable designers to achieve complex visual effects without additional screens, making overprinting a cost-effective choice for creating distinctive apparel designs that stand out in Phoenix’s competitive custom printing market.

Which Visual Effects Are Achievable with Overprint Screen Printing?

Overprint screen printing achieves unique visual effects through strategic ink layering and transparency manipulation. These techniques create color combinations, texture variations, and design complexities impossible with standard single-layer printing methods.

What Colors and Opacities Can Be Created with Overprinting?

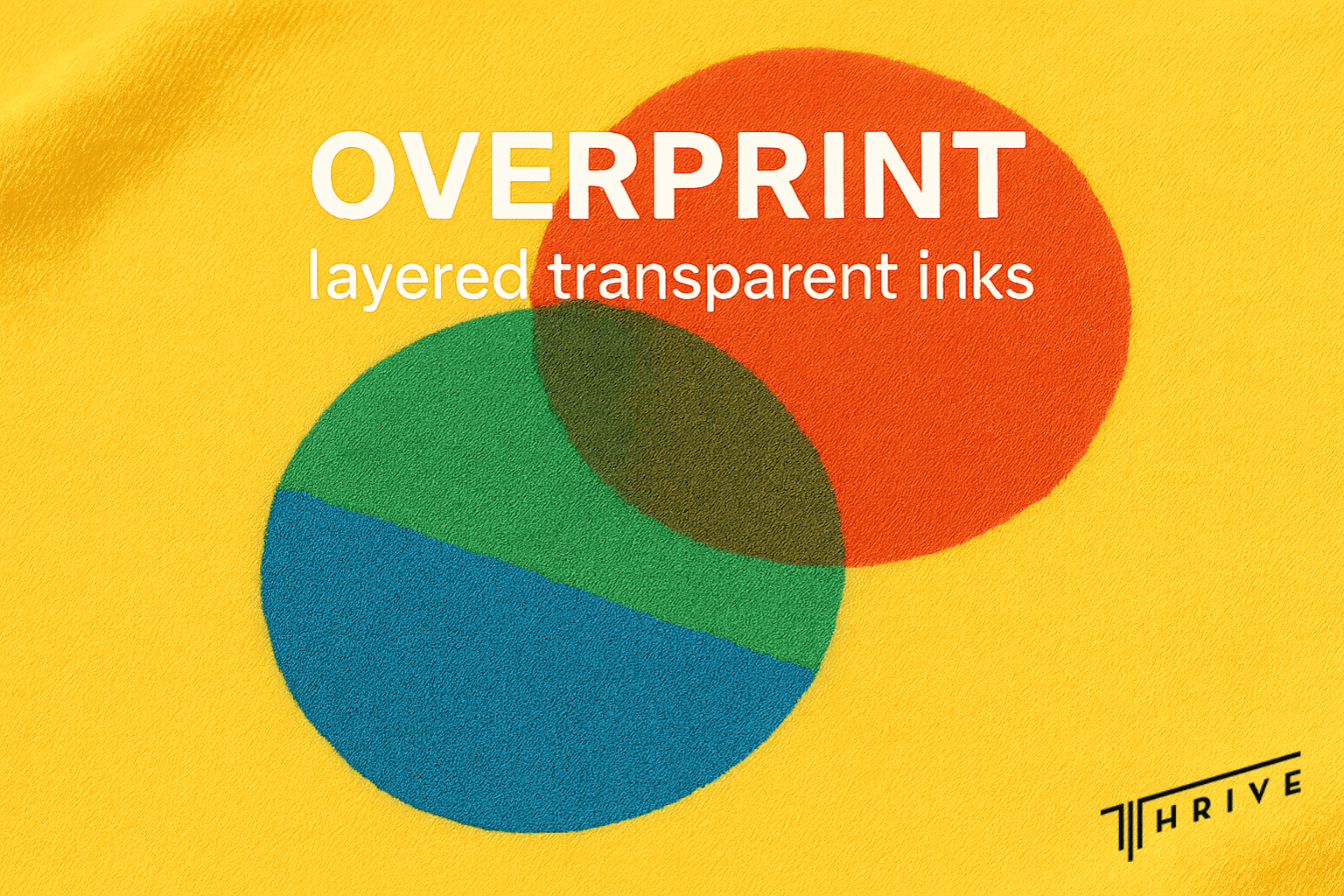

Overprinting creates color variations through controlled ink transparency and layering techniques. Red ink appears lighter when overlapping white ink while appearing darker when printed directly on fabric. Yellow overprinting cyan produces green hues through additive color mixing.

Ink opacity measures how much light passes through each ink layer, also called ink density. Quality pad printing inks milled to 3 microns provide superior hiding power compared to standard formulations. Black ink frequently prints over other colors, with 100% black on different base colors producing denser, richer black tones.

Opacity and Color Control Options:

- Transparent inks allow base colors to show through top layers

- Semi-opaque inks create subtle color shifts and tonal variations

- High-opacity inks provide solid coverage while maintaining layering effects

- Specialty fluorescent inks enhance color vibrancy in overlapping areas

This color control enables designers to achieve multiple hues using fewer screens than traditional knockout methods.

How Does Overprinting Affect Textures and Layering?

Overprinting affects texture through ink thickness variations and layering sequences. The lithographic process uses cyan, magenta, yellow, and black color plates for systematic layering. Transparency factors in inks allow controlled color mixing when multiple layers overlap.

Screen printing ink with larger micron sizes results in less hiding power but creates tactile texture variations. Each additional layer builds visual depth while maintaining the base design’s integrity. Strategic layering produces gradient-like transitions between overlapping color zones.

Texture Enhancement Methods:

- Variable ink thickness creates raised surface effects

- Multiple transparent layers build color depth gradually

- Overlapping opaque and transparent inks produce mixed texture zones

- Sequential layering maintains design registration while adding complexity

These layering techniques enable complex visual effects using standard screen printing equipment.

What Are Examples of Unique Overprint Designs in Apparel?

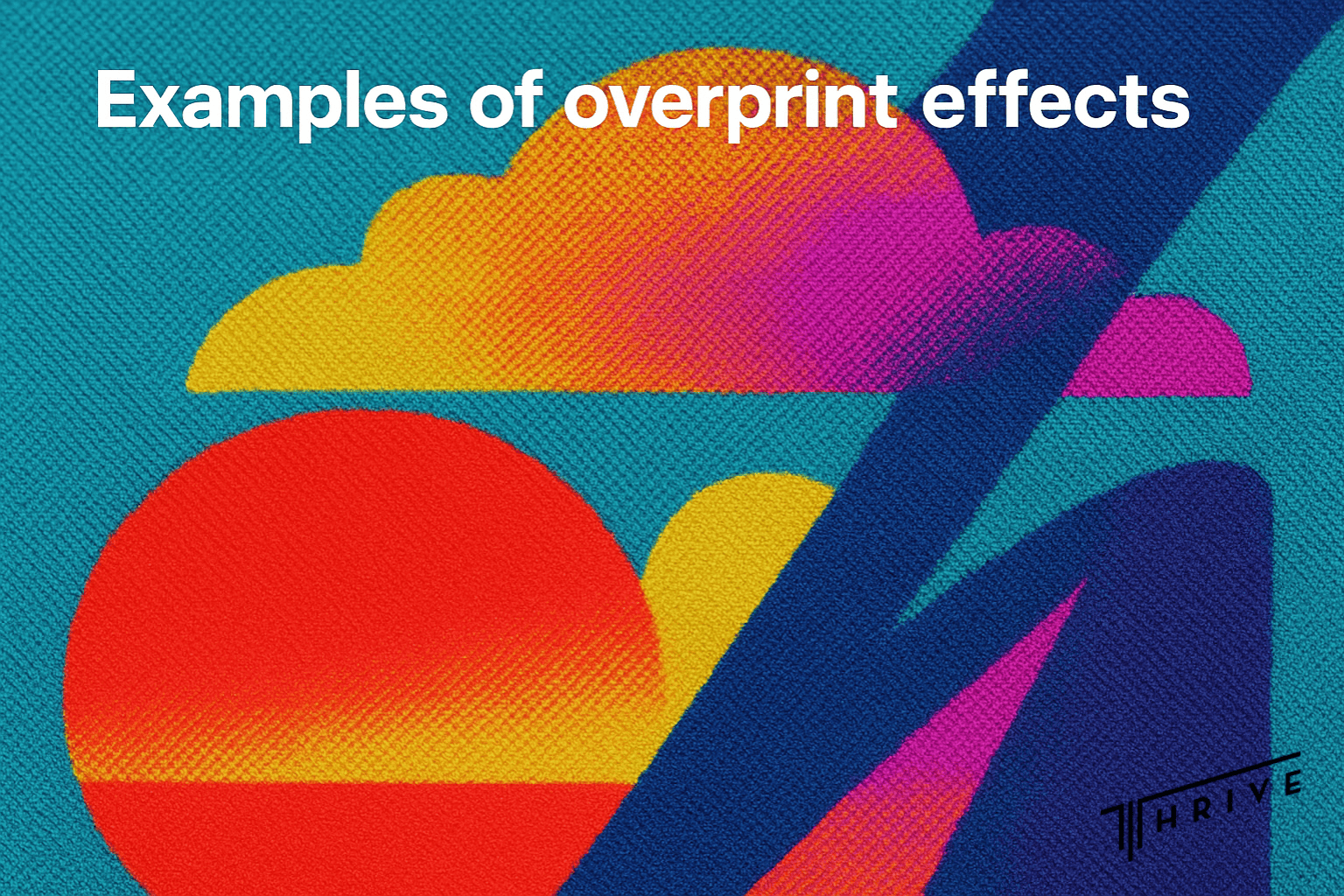

Unique overprint designs in apparel showcase creative color combinations and special effect applications. Fluorescent inks with overlapping colors create vibrant, attention-grabbing designs that shift appearance under different lighting conditions. Color mixing effects allow base colors to show through top layers, creating gradient-like appearances without complex color separations.

Popular overprint applications include sunset effects using red and yellow transparency overlays, ocean designs combining blue and green translucent inks, and vintage-style graphics using sepia-toned overprints. These designs leverage Phoenix’s bright sunlight to enhance fluorescent ink visibility during outdoor events and festivals.

Design Categories for Overprinting:

- Gradient effects using overlapping transparent colors

- Vintage designs with sepia or aged color overlays

- Fluorescent accent designs for high-visibility applications

- Abstract patterns using strategic color bleeding effects

These overprint techniques enable Thrive Screen Printing to create distinctive apparel designs that stand out in Phoenix’s competitive custom printing market while maintaining production efficiency.

What Materials and Garments Work Best for Overprint Screen Printing in Phoenix?

Material selection directly impacts overprint quality in Phoenix’s extreme desert conditions. Cotton provides the most reliable foundation for overprinting effects, while synthetic fabrics require specialized inks and techniques. Phoenix’s intense heat and low humidity create unique challenges that demand climate-specific material choices and ink formulations.

Are Certain Fabrics More Compatible with Overprinting Effects?

Certain fabrics excel for overprinting applications due to their ink absorption and layering properties. Cotton remains the most popular fabric for screen printing applications, offering excellent ink penetration and color mixing capabilities essential for overprint effects. Synthetic fabrics like polyester and nylon require ink types that bond effectively with synthetic fibers, making low-bleed plastisol inks the recommended choice for synthetic materials.

Fabric compatibility varies significantly across materials:

- Cotton tees provide ideal surfaces for traditional screen printing with superior ink absorption

- Synthetic fabrics work better with heat transfers due to their polymer structure

- Silk requires adhesive for proper ink adherence before overprinting begins

Each fabric type affects how overprinted colors blend and appear in the final design, with cotton delivering the richest color mixing effects.

How Does Climate in Phoenix Influence Material and Ink Choices?

Phoenix’s desert climate with temperatures routinely climbing above 100°F affects ink selection and material performance throughout the printing process. Humidity often dips below 20% in Phoenix, creating rapid evaporation conditions that impact both water-based and plastisol inks differently.

| Ink Type | Optimal Temperature | Phoenix Challenge | Solution |

| Plastisol | Above 75°F | Gelling at 180-240°F | Climate-controlled facilities |

| Water-based | 60-80°F | Fast evaporation above 110°F | Modified formulations |

| UV-resistant | 65-85°F | Extended curing in 115°F+ heat | Specialized equipment |

Temperature extremes create specific challenges: ideal temperature for plastisol inks is above 75°F, but below this temperature increases viscosity making manual screen printing challenging. Conversely, excessive heat range of 180°F to 240°F starts the gelling process making inks thicker and harder to print. Phoenix temperatures often exceed 110°F with over 300 sunny days annually, requiring climate-appropriate techniques and storage solutions.

Which Apparel Types Are Most Popular for Overprint Screen Printing?

Cotton garments retain more moisture, requiring longer drying time during humid days, though Phoenix’s low humidity typically accelerates this process. The garment must reach 212°F before the curing process can start, making material thickness and composition critical factors.

Popular apparel choices include:

- 100% cotton t-shirts for maximum color saturation

- Cotton-poly blends for durability and cost efficiency

- Performance synthetics for athletic applications

- Premium cotton for high-end promotional items

These materials provide optimal foundations for overprint techniques while withstanding Phoenix’s intense UV exposure and temperature fluctuations throughout the year.

What Are the Main Advantages and Challenges of Using Overprint Effects?

Overprint effects offer distinct advantages in screen printing while presenting specific technical challenges that require careful consideration. The technique creates unique visual outcomes through layering but demands proper setup and material selection. Understanding both benefits and potential issues helps businesses and designers make informed decisions about incorporating overprint techniques into their Phoenix apparel projects.

How Does Overprinting Enhance Print Depth and Complexity?

Overprinting enhances print depth through transparency and layering effects that create unique color combinations. The technique produces new hues by combining colors without requiring additional screens, offering cost-effective design flexibility. Fluorescent inks particularly benefit from overprinting, creating special effects through their natural transparency properties. These overlapping color effects generate visual complexity impossible to achieve with standard single-layer printing methods.

The layering process allows base colors to show through top layers, creating gradient-like appearances and dimensional effects. According to industry standards, quality pad printing inks milled to 3 microns provide superior hiding power while maintaining transparency for effective overprinting. This depth enhancement makes designs more visually engaging without significantly increasing production complexity.

What Technical Challenges Could Occur with Overprinting?

Technical challenges in overprinting require careful attention to prevent printing errors and design flaws. White objects should never be set to overprint, as standard white ink is not used in the overprinting process and will not appear in the final printed output. Incorrect spot color settings can occur with improper overprint configurations, leading to unexpected color variations.

Common technical issues include:

- Conspicuous patterns appearing in unintended design areas

- Unintentionally masked or obscured design elements

- Reduced readability of printed text or data

- Shadow effects from misalignment in white base coat methods

Proper file preparation and verification of output attributes are essential to control overprint settings effectively. Phoenix’s extreme temperatures, often exceeding 115°F, can exacerbate technical challenges by affecting ink viscosity and drying times during production.

Are There Durability or Care Considerations for Overprinted Apparel?

Durability considerations for overprinted apparel depend on proper ink formulation and curing processes. High-quality screen printed materials typically last 10+ years with proper care, while standard screen-printed clothing maintains quality for 5-10 years. Outdoor exposure reduces lifespan to 1-5 years depending on UV exposure intensity.

Durability Factors:

| Factor | Performance Standard | Phoenix Consideration |

| UV Resistance | 90% color density after 500 hours testing | Critical due to 300+ sunny days annually |

| Wash Cycles | Color retention after 50+ cycles | Enhanced with UV-resistant formulations |

| Weather Resistance | Resists fading, cracking, outdoor elements | Extra protection needed for 110°F+ temperatures |

| Accelerated Testing | Industry standard weathering protocols | Simulates Phoenix desert conditions |

Properly formulated UV-resistant inks maintain superior performance in Phoenix’s intense sunlight, though they cost approximately 15-20% more than standard formulations. Quality measurement focuses on print sharpness, ink adherence, and color retention under extreme conditions typical of Arizona’s desert climate.

What Should Businesses and Designers in Phoenix Consider Before Choosing Overprint Effects?

Businesses and designers in Phoenix should evaluate branding objectives, design requirements, and production constraints before implementing overprint effects. The screen printing market demonstrates substantial growth potential, with screen printing holding 56% of the global custom t-shirt printing market revenue share in 2024.

How Can Overprinting Support Branding or Promotional Goals?

Overprinting supports branding goals by creating distinctive visual effects that enhance brand recognition and promotional impact. The global screen printing segment revenue reached USD 20,743.3 million in 2024, indicating strong market demand for specialized printing techniques. According to industry data from 2024, the overprint varnishes market valued at USD 3.42 billion demonstrates significant commercial investment in layering technologies.

Overprint effects offer unique color combinations that standard printing cannot achieve, making branded materials more memorable and visually striking. The North American overprint varnish market reached USD 267.0 million in 2023 with 9.6% CAGR from 2024 to 2032, reflecting growing adoption of advanced printing techniques for promotional materials.

The following section examines specific design requirements that influence overprint success.

What Design Aspects Should Be Evaluated Before Printing?

Design aspects requiring evaluation before overprinting include file format compatibility, color specifications, and material adhesion properties. File types accepted include .AI, .EPS, .SVG in vector format to ensure precise color registration and scaling accuracy.

Verification of file output attributes is needed to control overprint settings and prevent unintended color mixing or transparency effects. The ink binder system must be compatible with product material for proper transfer and adhesion, preventing peeling or cracking after curing.

Key evaluation criteria include:

- Color opacity relationships between layers

- Registration tolerance for multi-layer designs

- Substrate compatibility with overprint inks

- Curing temperature requirements for layered applications

Design fees typically start at $75 per design including up to 3 revisions, covering technical optimization for overprint compatibility. These evaluations directly impact production scheduling and cost calculations.

How Does Overprinting Impact Production Time and Cost in Phoenix?

Overprinting impacts production time through additional layering steps and specialized curing requirements. Standard turnaround time is 7-10 business days for most orders, with simple designs featuring 1-3 colors completing in 5-8 business days. Complex orders with many colors require 8-12 business days due to multiple screen setups and curing cycles.

Production efficiency varies significantly by equipment type, with manual presses producing over 100 items per hour while automatic presses produce 300-700 items per hour. Screen fees start at $25 per screen per location, with additional color charges of $0.50 per additional color per garment affecting total project costs.

Cost Factors in Phoenix Overprinting:

| Factor | Standard Rate | Overprint Variation | Notes |

| Screen fees | $25 per screen | +$25 per layer | Per location |

| Color charges | $0.50 per color | +$0.50 per layer | Per garment |

| UV-resistant inks | Standard pricing | +15-20% premium | Phoenix climate requirement |

| Process efficiency | Baseline | 15-20% time savings | With optimized setup |

UV-resistant inks cost approximately 15-20% more than standard formulations but provide necessary durability in Phoenix’s intense sunlight. Efficient processes save 15-20% of print time when properly planned, offsetting some additional costs through improved throughput.

This comprehensive evaluation framework guides businesses toward successful overprint implementations that balance visual impact with practical production constraints.

How Should You Approach Overprint Screen Printing Effects with Thrive Screen Printing?

Can Thrive Screen Printing Help with Achieving Custom Overprint Effects in Phoenix?

Thrive Screen Printing specializes in custom overprint effects through its state-of-the-art 40,000 square foot facility in Phoenix, Arizona. The company operates 5 automatic presses and 2 manual presses, delivering production capacity up to 20,000 prints in a single 8-hour shift.

Thrive’s equipment handles complex overprint projects efficiently, printing 10 colors in under a minute for large-scale orders. The facility uses climate-appropriate techniques specifically designed for Phoenix conditions, employing high-opacity inks resistant to UV degradation. Curing temperatures range from 280-320°F, ensuring permanent adhesion essential for overprint layering effects.

The company maintains a +98% shipment accuracy rating, demonstrating precision crucial for overprint alignment and color registration. Located at 3050 S 44th St, Phoenix, AZ 85040, Thrive provides local expertise for Phoenix-area businesses requiring specialized overprint screen printing services. Contact them at 602-607-2171 for custom overprint consultations.

What Are the Key Takeaways About Overprint Screen Printing Effects in Phoenix We Covered?

Overprint screen printing in Phoenix requires specialized climate considerations and proper facility management. Phoenix demands climate-controlled facilities to prevent under-curing or spoilage, particularly important for layered overprint applications where multiple ink layers must cure properly.

Technical requirements include plastisol inks requiring 320°F curing temperatures for permanent adhesion. Screen printing businesses must operate in commercial or light industrial zoning (C-2 or A-1 districts) within Phoenix regulations. Advanced Screen Print Supply serves as the local supplier for specialized inks, screens, and equipment needed for overprint effects.

Climate challenges significantly impact production processes:

- High temperatures accelerate ink drying rates

- Water-based inks can clog screens in low-humidity conditions

- Cold weather storage requires keeping inks on highest shelves in insulated rooms

- Hot weather storage demands cool spaces away from direct sunlight on lower shelves

These Phoenix-specific considerations ensure successful overprint screen printing projects that maintain color integrity and proper layering effects in the desert climate.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.