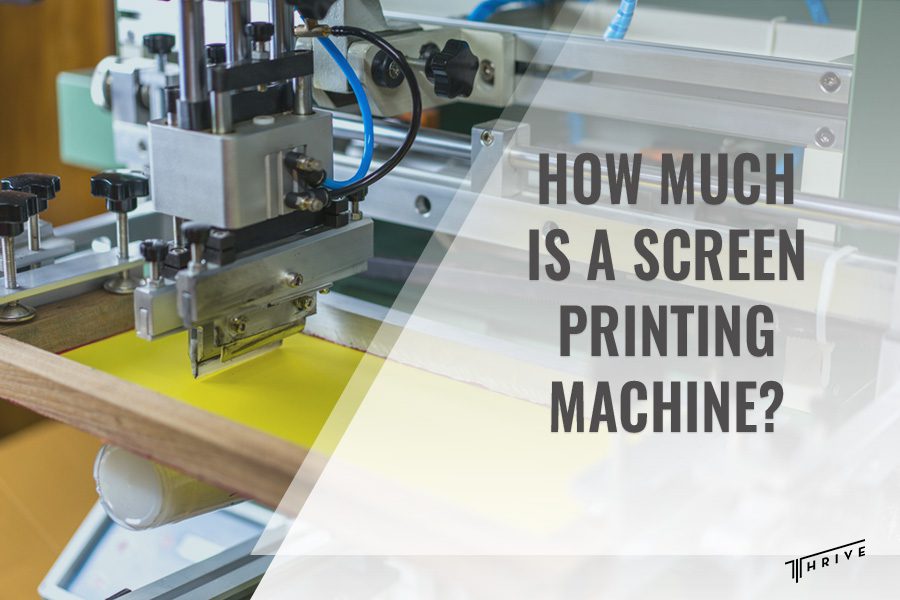

Screen printing is widely used for printing designs onto various surfaces, from T-shirts and posters to banners and circuit boards. You’ve probably seen screen-printed items all around you, even if you didn’t realize it. It’s a popular choice because it can create vibrant and long-lasting prints on various materials.

But here’s the thing: behind every great screen-printed item, there’s a screen-printing machine doing the heavy lifting. These machines are like the magic wands of the printing world. They’re responsible for transferring your favorite designs onto different surfaces with precision and consistency.

So, how much is a screen printing machine? In this article, we will see the factors that influence the price of a screen printing machine. We will also talk about the different types of machines, what makes them pricier or more affordable, and even share estimates for various screen printing machines.

If you’re curious about the dollars and cents of screen printing equipment, stick around, and let’s dive in!

How Much Is a Screen Printing Machine?

Manual screen printing machines can start at a few hundred dollars, while semi-automatic and fully automatic machines can range from several thousand to tens of thousands of dollars.

The factors that contribute to the overall cost of a screen printing machine include various aspects such as the type of machine, its capabilities, technology, brand reputation, and whether it’s new or pre-owned.

Additionally, shipping and delivery costs for a screen printing machine depend on location, shipping method, machine size, and insurance.

Now, before we go further into the details of “How much is a screen printing machine?”, let’s look at the different types of screen printing machines available in the market.

Types of Screen Printing Machines

- Manual screen printing machines

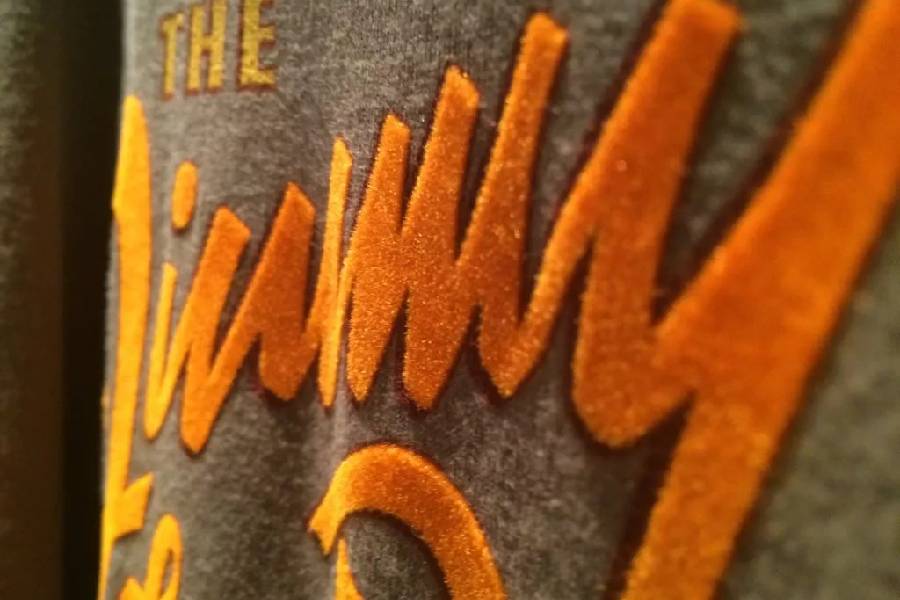

Manual screen printing machines are like the dependable workhorses of the screen printing world. They’re perfect for smaller-scale operations and custom designs. With these machines, you have hands-on control.

The process is that you place the ink on the screen and use a squeegee to press it onto the material, whether it’s a T-shirt, poster, or something else. The advantage is your control over each print, but it’s a bit slower because you do one print at a time. Manual machines are often an excellent choice for artists and small businesses.

- Semi-automatic screen printing machines

Semi-automatic screen printing machines strike a balance between manual and fully automatic machines. They’re like the middle path. With these machines, you can handle more prints in less time compared to manual ones because they have some built-in automation.

However, you still load your material and apply the ink, but the machine assists with the printing part. This makes them a popular choice for businesses that need more speed and efficiency but still want some control over the process.

- Fully automatic screen printing machines

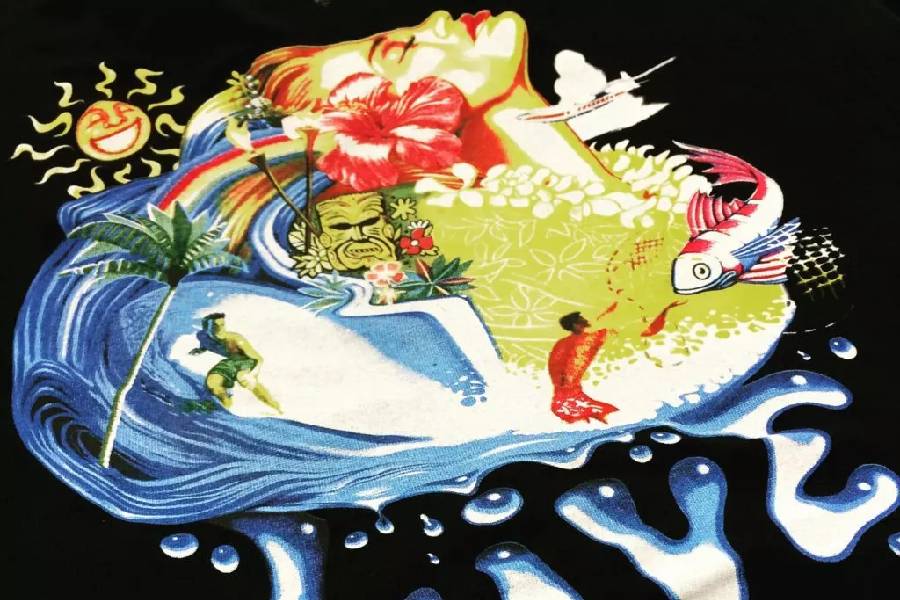

Fully automatic screen printing machines are the speedsters in the screen printing world. They’re designed for large-scale production. With these machines, you load your material, set things up, and let the machine take over.

They can print fast and are often used in big production settings where speed is crucial. However, they can be pretty expensive and may not provide the same level of artistic control as manual or semi-automatic machines.

Factors Affecting Screen Printing Machine Costs

Type of machine

The type of screen printing machine you opt for is a primary determinant of its cost. There are three main categories: manual, semi-automatic, and fully automatic machines. Manual machines, which require more hands-on operation, are the most budget-friendly.

Semi-automatic machines balance manual and fully automatic, offering enhanced efficiency at a moderate price point. On the other hand, fully automatic machines are the most advanced and come with a higher price tag due to their automation capabilities.

Size and capacity

The physical dimensions and production capacity of the machine are critical considerations. Larger machines, capable of handling larger print sizes or higher quantities of prints in a single run, generally have a higher price.

When choosing a machine, it’s essential to consider your production needs and budget.

Technology and features

The technology and features incorporated into a screen printing machine can significantly impact its cost.

Advanced features such as touchscreen controls, automated registration systems, and integrated drying units can enhance efficiency and print quality but may also add to the machine’s price. So, carefully evaluate which features align with your production requirements and budget constraints.

Brand reputation

The reputation and credibility of the manufacturer can influence pricing. Well-established brands with a history of producing reliable and durable machines may offer their products at a premium price.

While investing in reputable brands can provide peace of mind, balancing brand recognition with your budgetary considerations is essential.

New vs. used machines

One of the most significant cost differentiators is whether you choose a new or used screen printing machine. New machines typically come with a higher upfront cost but offer the benefit of a warranty and the latest technology.

Used machines are often more budget-friendly but require careful evaluation for their condition, maintenance history, and potential hidden costs. Used machines can be less expensive but may require more regular maintenance and a shorter lifespan.

Additional costs

In addition to the machine’s base price, consider other expenses such as shipping and delivery fees. As we mentioned, the size and weight of the machine, along with your location, can also influence the costs.

Cost Estimates for Screen Printing Machines

Price ranges for manual machines

Manual screen printing machines are a budget-friendly choice, making them ideal for small businesses and beginners. You can find entry-level manual machines for around $200 to $500.

If you’re looking for more features and durability, mid-range models range from $500 to $2,000. For professional-grade machines designed for heavy use, prices may go from $2,000 to $5,000 or more.

Price ranges for semi-automatic machines

Semi-automatic screen printing machines offer a sweet spot between control and productivity. You can find entry-level semi-automatic machines for approximately $1,000 to $3,000.

As you move up to models with larger print areas and enhanced automation, you might be looking at prices between $3,000 and $10,000. For industrial-grade semi-automatic machines built for high-volume production, budgets of $10,000 to $30,000 or more may be necessary.

Price ranges for fully automatic machines

Fully automatic screen printing machines may be the best in the screen printing world, and their prices reflect that. So, how much is a screen printing machine of this type? Entry-level models can begin at $10,000 to $20,000, but keep in mind that these are often more suited to specialized tasks.

Mid-range fully automatic machines, capable of handling larger print runs, range from $20,000 to $50,000. For top-of-the-line, heavy-duty, and industrial-grade models, budgets can extend from $50,000 to $200,000 or even more.

Potential Hidden Costs and Maintenance Expenses

While purchasing a screen printing machine is a significant expense, don’t forget about potential hidden costs and ongoing maintenance. For example, that can be expenses for replacement parts, routine upkeep, and necessary repairs.

Replacement parts can encompass a range of items, from screens and squeegees to various mechanical components. The cost of these replacements should be incorporated into your budget, as they are essential for the continued functionality of the machine.

Additionally, consider the costs related to maintaining a safe and efficient workspace, including proper ventilation and safety gear. Investing in maintenance and safety ensures your machine’s longevity and smooth operation.

Frequently Asked Questions

Why is screen printing so expensive?

It can be expensive due to several factors. First, it requires the creation of screens for each color in the design, which incurs setup costs. Additionally, labor-intensive tasks like screen preparation, ink mixing, and manual printing contribute to the expense.

Moreover, economies of scale play a role, as smaller print runs can be relatively costlier per unit. High-quality materials and customization also add to the overall cost.

What is cheaper, screen printing or a heat press machine?

The cost-effectiveness of screen printing versus a heat press machine depends on the volume and type of printing you plan to do. Screen printing can be more cost-effective for larger production runs because the per-unit cost decreases as the quantity increases.

Heat press machines are often more suitable for smaller, on-demand printing jobs. Consider your production needs, initial investment, and operating costs to determine which method is more economical for your specific situation.

How much is a t-shirt printing machine?

The price of a t-shirt printing machine varies depending on the type and complexity of the machine. For a basic manual t-shirt printing machine, you can expect to pay anywhere from a few hundred to a few thousand dollars.

Semi-automatic and fully automatic machines are more expensive, ranging from several thousand to tens of thousands of dollars. Additionally, factors like brand, size, and features play a significant role in determining the price.

Conclusion

To sum up, how much is a screen printing machine? Various factors, including the type of machine, hidden expenses, and ongoing maintenance, influence the cost of a screen printing machine. Making a well-informed decision is not only about budget but also about ensuring the long-term success of your screen printing ventures.

We hope our article will help you make the right decision based on your unique needs. Take your time in selecting the perfect screen printing machine that fits both your vision and your budget.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.