If you’re exploring heat press finishing options for your screen printing projects in Phoenix, you’ve come to the right place. We understand that navigating the world of garment decoration can be overwhelming, especially when trying to achieve professional results in Arizona’s unique climate. Whether you’re a business owner looking to produce custom apparel or a designer seeking the best finishing method for your creations, we’ll guide you through everything you need to know about heat press finishing in the Valley of the Sun.

Heat press finishing is a critical post-press process that applies precise combinations of temperature (260°F-400°F), pressure (40-80 PSI), and time (5-30 seconds) to cure ink and create durable, professional-quality decorated garments. In Phoenix’s extreme heat and low humidity environment, this process requires special attention to equipment settings, material handling, and quality control to ensure optimal results.

TL;DR Summary: We’ll explore how heat press finishing works through temperature, pressure, and time calibration, examining the crucial steps and equipment involved. You’ll discover the key benefits including improved durability, enhanced appearance, and advantages for custom prints. We’ll cover common applications across Phoenix industries and how local businesses utilize this technology. Understanding Phoenix’s unique climate impact and regulations is essential, so we address environmental factors and compliance requirements. Finally, we’ll help you choose the right finishing method by evaluating factors, limitations, and quality assurance strategies, with insights into how Thrive Screen Printing can support your projects.

Quick Tip: Always perform test prints on scrap material before starting any production run—Phoenix’s low humidity can affect transfer adhesion differently than in other climates, so verifying your settings saves time and materials.

The decorated apparel industry in Phoenix presents unique opportunities and challenges, with heat press finishing serving as a versatile solution for businesses ranging from startups to established operations. As we dive deeper into the technical aspects and practical applications, you’ll gain the knowledge needed to make informed decisions about your screen printing finishing needs in our desert metropolis.

How Does Heat Press Finishing Work in Screen Printing?

Heat press finishing works by applying precise combinations of temperature, pressure, and time to cure inks and bond transfers to garments. This process requires specific parameters ranging from 260°F-400°F temperature, 4-8 pressure settings on manual presses, and 5-30 second dwell times depending on the application. The following sections detail each critical aspect of the heat press finishing process.

What Are the Steps Involved in the Heat Press Finishing Process?

The steps involved in the heat press finishing process are pre-heating, placement, pressing, and quality verification. Standard plastisol transfers on 100% cotton require 325-350°F for 10-12 seconds at medium pressure. According to Stahls’, the process demands a calibrated balance of heat, pressure, and time elements to achieve optimal results.

Test prints on scrap material verify settings before every production run. Regular equipment calibration ensures accurate and even temperature and pressure distribution across the platen surface. Each job requires documentation of specific settings for ink type, fabric composition, and transfer material to maintain consistency.

Why Is Temperature and Pressure Crucial for Heat Press Finishing?

Temperature and pressure are crucial for heat press finishing because incorrect settings lead to under-cured prints that wash out or over-cured, scorched garments. Hotronix specifies pressure settings from 1-9, where 4-6 represents medium pressure suitable for most standard applications.

Parameters vary based on several factors:

- Ink system type (plastisol, water-based, DTF)

- Fabric composition (cotton, polyester, blends)

- Transfer material specifications

- Garment thickness and construction

Pressure must remain even across the platen to ensure consistent bonding. Low-temperature cures are becoming popular for delicate synthetic fabrics that cannot withstand traditional heat levels.

What Types of Equipment Are Used for Heat Press Finishing?

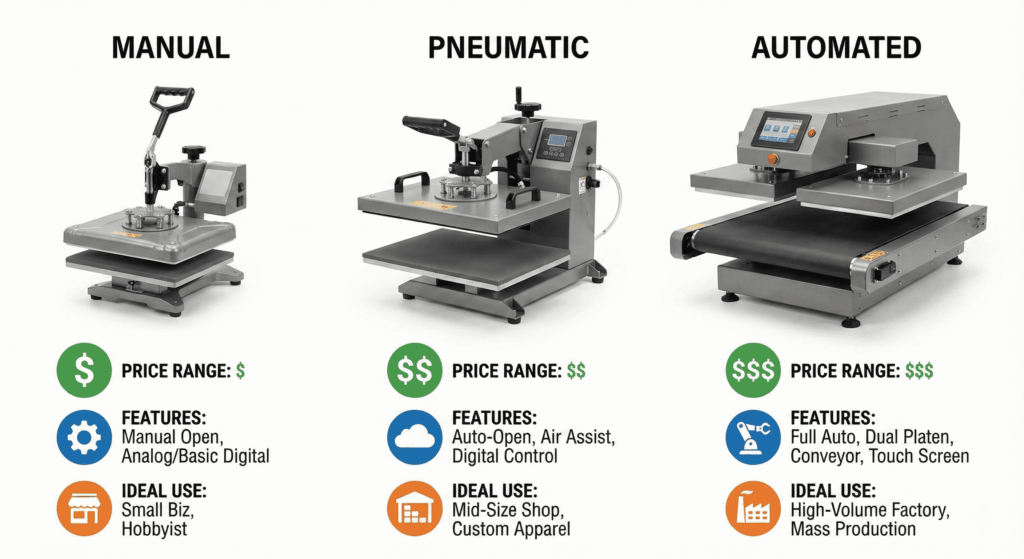

The types of equipment used for heat press finishing are manual heat presses, pneumatic presses, and intelligent automated systems. Equipment investment ranges from $500-$3,000 for basic heat press setups suitable for small operations.

Modern intelligent heat presses feature programmable presets, digital pressure readouts, and automated opening capabilities. Automatic screen printing presses require safety guards for moving parts per OSHA standards. Current heat presses incorporate energy-efficient technology for sustainability and cost management in demanding climates like Phoenix.

Designed Ink in Phoenix uses a mix of new and quality used equipment including automated screen coaters to maintain competitive pricing while ensuring quality output. This approach demonstrates how strategic equipment selection balances investment costs with production capabilities.

What Are the Benefits of Heat Press Finishing for Screen Printing Projects?

Heat press finishing offers significant advantages for screen printing projects through enhanced durability, improved appearance, and specialized application capabilities. This process creates stronger ink-to-fabric bonds while enabling precise multi-color designs and cost-effective small-run production.

How Does Heat Press Finishing Improve Print Durability?

Heat press finishing provides excellent durability ratings for decorated garments by ensuring proper ink bonding to fabric fibers. The controlled curing process creates molecular bonds that resist washing, UV exposure, and regular wear. Quality assurance includes wash testing through multiple wash-and-dry cycles to verify longevity.

Thrive Screen Printing uses high-opacity inks resistant to UV degradation to guarantee apparel remains vivid even under Phoenix’s intense sunlight. Documentation of settings for specific jobs, ink types, and fabrics ensures repeatability and consistent quality across production runs. This systematic approach maintains durability standards while enabling efficient scaling.

Key durability factors include:

- Proper temperature and pressure application creates strong molecular bonds

- UV-resistant inks prevent fading in high-exposure environments

- Standardized testing protocols verify wash resistance

- Equipment calibration ensures consistent curing parameters

This thorough approach to durability enhancement connects directly to improved garment appearance quality.

In What Ways Can Heat Press Finishing Enhance the Appearance of Garments?

Heat press finishing enhances garment appearance through precise multi-color designs with exceptional detail and professional smoothness. Direct-to-Film (DTF) technology produces full-color, detailed designs without the weeding required for heat transfer vinyl, enabling complex graphics with photographic quality.

The process accommodates various decoration types including flock, foil, gel, and high-density applications for specialized visual effects. Low-temperature cure inks prevent scorching on sensitive fabrics while maintaining print quality. Even pressure distribution across the platen ensures smooth, professional-looking transfers without texture variations or incomplete adhesion.

Appearance enhancement features:

- Multi-color capability with photographic detail precision

- Specialty finishes like foil and high-density for premium effects

- Temperature control prevents fabric damage and scorching

- Uniform pressure creates smooth, consistent surface quality

These appearance benefits extend naturally into specialty and custom printing applications.

Does Heat Press Finishing Offer Advantages for Specialty or Custom Prints?

Heat press finishing excels for specialty and custom prints through low investment requirements and versatile material compatibility. DTF technology offers versatility across cotton, polyester, nylon, and leather materials with initial investment of $500-$3,000 compared to screen printing’s $5,000-$50,000+ setup costs.

Heat press transfers excel for small runs and personalization projects without high minimum orders. This makes the method ideal for on-demand production, allowing businesses to fulfill custom requests efficiently. The process accommodates specialty applications that companies like Thrive Screen Printing offer, including complex multi-substrate projects and limited-edition designs.

Custom print advantages:

- Low barrier to entry with minimal equipment investment

- No minimum order requirements enable single-piece customization

- Material versatility spans natural and synthetic fabrics

- On-demand capability reduces inventory and storage needs

Heat press finishing provides essential benefits spanning durability, appearance, and specialization that make it a cornerstone technology for Phoenix screen printing operations seeking competitive advantages in quality and flexibility.

What Are the Most Common Applications of Heat Press Finishing in Phoenix?

Heat press finishing serves diverse applications across Phoenix’s vibrant printing industry, from small-scale promotional items to large uniform programs. Arizona’s printing industry represents a $774.8 million market with 893 businesses employing 5,276 people as of 2025, creating substantial demand for heat press services. The following sections explore the primary industries utilizing heat press finishing and the specific applications driving this demand.

Which Industries or Businesses Frequently Use Heat Press Finishing?

Phoenix hosts one of the most competitive print markets in the country, where diverse industries rely on heat press finishing for their branded materials. Small brands and creators need reliable partners for high-quality, on-demand DTF transfers that heat press technology delivers efficiently. The city’s growing tech and manufacturing sectors require specialized promotional products, from employee uniforms to trade show giveaways.

Key industries utilizing heat press finishing include:

- Corporate businesses for employee uniforms and promotional merchandise

- Sports teams and schools for custom apparel and spirit wear

- Event planners requiring branded materials for conferences and trade shows

- Retail businesses creating limited-run merchandise lines

The market’s competitive nature drives businesses to seek cost-effective solutions for smaller quantities, making heat press finishing an attractive option compared to traditional screen printing minimums.

How Is Heat Press Finishing Applied to Apparel and Promotional Items?

Thrive Screen Printing operates from a 40,000-square-foot facility with capacity to design, print, and ship up to 24,000 items daily, demonstrating the scale at which heat press applications occur. Heat press finishing serves uniform programs managed through online portals like DecoNetwork, streamlining order processing and quality control.

Common applications include:

- Custom t-shirts and polo shirts for corporate events

- Promotional tote bags and hats for marketing campaigns

- Sports jerseys with player names and numbers

- Work uniforms with company logos and employee identification

Cost considerations significantly impact application choices. A 100-shirt order costs approximately $4 per shirt with heat transfers versus $0.25-$0.50 per shirt with screen printing, making heat presses ideal for smaller quantities. QR-coded samples linked to supplier catalogs reduce the need for large physical inventory while maintaining quality standards.

Can Heat Press Finishing Be Used on Various Fabrics and Materials?

DTF technology works on cotton, polyester, nylon, leather, and fabric blends, providing versatility for diverse material applications. Standard settings vary significantly: 100% cotton requires 325-350°F while polyester needs lower temperatures to prevent scorching. Longer dwell times up to 30 seconds accommodate thicker materials, while shorter times of 5 seconds minimum protect sensitive fabrics from damage.

Material compatibility extends to:

- Natural fibers like cotton and linen for casual wear

- Synthetic blends for athletic and performance apparel

- Specialty materials including leather goods and canvas bags

- Eco-friendly fabrics requiring PVC-free transfers

This material versatility positions heat press finishing as a comprehensive solution for Phoenix businesses requiring decorated items across various product categories, from lightweight promotional shirts to heavy-duty work uniforms.

What Environmental and Regional Factors Affect Heat Press Finishing in Phoenix?

Environmental and regional factors significantly impact heat press finishing operations in Phoenix, requiring specialized adaptations for optimal results. Phoenix’s extreme desert climate and regulatory environment create unique challenges that screen printing businesses must address through modified techniques and compliance protocols.

How Does Phoenix’s Climate Impact the Heat Press Process?

Phoenix’s climate directly affects heat press operations through extreme temperatures and low humidity conditions. The city experiences temperatures exceeding 110°F in summer with relative humidity often below 20%, creating significant challenges for consistent finishing results.

High ambient temperatures pre-warm garments before pressing, requiring operators to reduce press temperatures by 15-25°F and decrease dwell times by 2-4 seconds to prevent over-curing. Heat reduces ink viscosity, making inks thinner and more prone to bleeding beyond intended boundaries. Materials stored in non-climate-controlled environments lose residual moisture, causing transfers to become brittle and prone to cracking during application.

Phoenix’s extreme heat and low humidity cause inks to dry faster on screens, reducing working time and requiring more frequent ink additions during production runs. Climate-controlled storage becomes essential for maintaining transfer quality and preventing premature deterioration of heat-sensitive materials.

What Local Regulations or Best Practices Apply to Finishing Techniques?

Phoenix screen printing operations must comply with Arizona Division of Occupational Safety and Health (ADOSH) standards alongside federal OSHA requirements. These regulations ensure worker safety and environmental protection in heat press finishing operations.

Hazard Communication (HazCom) standards require proper chemical labeling, Safety Data Sheets maintenance, and comprehensive employee training on ink and solvent handling. Lockout/Tagout (LOTO) procedures are mandatory for de-energizing heat press machinery during maintenance and repair operations.

All presses with moving parts must have safety guards to prevent employee injuries, particularly important given the increased accident risk from heat-related fatigue in Phoenix’s climate. Water-based and algae-based inks are increasingly adopted to meet growing demand for eco-friendly practices and reduce volatile organic compound emissions in the desert environment.

The combination of extreme climate conditions and strict regulatory compliance creates a challenging but manageable operating environment that successful Phoenix screen printing businesses navigate through proper planning and equipment investment.

How Do You Choose the Right Heat Press Finishing for Your Screen Printing Needs?

Choosing the right heat press finishing for your screen printing needs requires evaluating investment costs, production volumes, labor requirements, and per-item economics. The decision impacts both immediate profitability and long-term business sustainability, particularly in Phoenix’s competitive printing market.

What Factors Should Be Considered When Selecting a Finishing Method?

The primary factors for selecting a finishing method are initial investment, production volume capacity, labor intensity, and cost per item. Heat press finishing offers low initial investment of $500-$3,000, making it ideal for small runs and startup operations. Screen printing requires higher setup investment of $5,000-$50,000+ but becomes cost-effective for runs exceeding 100 units, with per-item costs dropping to $0.25-$0.50 compared to heat transfer costs of approximately $4 per shirt for 100-unit orders.

DTF technology provides a moderate investment option ranging $3,000-$20,000, suitable for all run sizes while delivering full-color capability across cotton, polyester, nylon, and leather materials. Labor requirements vary significantly: heat press operations require moderate labor input, screen printing demands high setup labor for screen preparation and registration, while DTF needs low to moderate labor investment.

Energy-efficient equipment selection becomes critical for sustainability and cost management in Phoenix’s extreme climate, where ambient temperatures exceeding 110°F increase operational costs for climate-controlled production facilities.

These factors guide businesses toward the most economically viable finishing method based on their specific production needs and market positioning.

Are There Limitations or Challenges to Heat Press Finishing?

Heat press finishing faces significant limitations in Phoenix’s challenging market environment. The Phoenix printing market has experienced a -2.1% annual decline from 2020 to 2025, creating intense competition among the 893 printing businesses operating in Arizona’s $774.8 million market.

High ambient temperatures increase energy requirements to maintain climate-controlled production facilities, directly impacting operational costs. Heat press transfers carry higher per-item costs compared to screen printing for large volume orders, making them less competitive for bulk production runs.

Market saturation necessitates differentiation through efficiency improvements, quality enhancements, and specialized service offerings. Careful selection of screen mesh counts becomes essential to manage ink deposit consistency in hot, dry conditions where materials lose residual moisture and inks may dry faster on screens.

| Challenge | Impact | Solution Strategy |

| Market Decline | -2.1% annual shrinkage | Service diversification |

| Climate Costs | Higher energy bills | Equipment efficiency |

| Volume Economics | $4 vs $0.50 per item | Hybrid production methods |

These challenges require strategic adaptation and operational excellence to maintain profitability in Phoenix’s competitive landscape.

How Can Customers Ensure Quality Results from Heat Press Finishing Services?

Customers can ensure quality results through systematic testing protocols, documentation practices, and equipment maintenance standards. Regular wash testing validates durability through multiple wash-and-dry cycles, confirming that finished garments maintain appearance and structural integrity over time.

Maintaining detailed logs of settings used for specific jobs, ink types, and fabric combinations ensures repeatability and consistent quality across production runs. Equipment calibration protocols maintain accurate and even temperature and pressure distribution, preventing under-cured prints that wash out or over-cured, scorched garments.

Test applications on scrap material verify settings before production runs begin, reducing waste and ensuring optimal results. Smart management systems like DecoNetwork provide transparency through quote management, digital proofs, and approval tracking, enabling customers to monitor project progress and quality checkpoints.

These quality assurance measures protect both the customer’s investment and the service provider’s reputation while building long-term business relationships based on consistent performance.

This systematic approach to heat press finishing selection considers Phoenix’s unique market conditions while providing practical frameworks for making informed decisions about equipment investment, production methods, and quality control protocols.

How Should You Approach Heat Press Finishing for Screen Printing in Phoenix with Thrive Screen Printing?

Heat press finishing for screen printing in Phoenix requires partnering with experienced professionals who understand both technical excellence and climate-specific challenges. Thrive Screen Printing combines advanced equipment, specialized techniques, and deep local market knowledge to deliver superior results in Arizona’s demanding environment.

Can Thrive Screen Printing Help With Heat Press Finishing Projects in Phoenix?

Thrive Screen Printing provides comprehensive heat press finishing services from their 40,000-square-foot Phoenix facility. The company uses climate-appropriate techniques including high-opacity inks resistant to UV degradation, ensuring prints maintain vibrancy despite Arizona’s intense sun exposure.

Their production capabilities include:

- Daily capacity: Up to 24,000 items for high-volume contract printing

- Service range: Wholesale screen printing, DTG printing, and specialty applications

- Finishing options: Flock, foil, gel, high density, and retail apparel finishing

- Equipment scale: Professional-grade heat presses with precise temperature and pressure controls

Thrive Screen Printing’s specialized capabilities position them as a key resource in Arizona’s competitive printing market. Their facility accommodates both small custom orders and large wholesale contracts, making them versatile for diverse project requirements.

What Are the Key Takeaways About Heat Press Finishing for Screen Printing in Phoenix We Covered?

Success in Phoenix’s competitive printing market requires deep understanding of technical processes and strategic climate adaptation. The city’s extreme heat, low humidity, and UV intensity demand specialized approaches that standard operations may not address.

Key strategic considerations include:

- Market opportunities: Eco-friendly printing specialization and on-demand DTF services for small businesses represent growing segments

- Technology investment: Smart investment in automated presses and DTF equipment drives efficiency and quality consistency

- Compliance requirements: Maintaining strict adherence to ADOSH/OSHA standards and quality control protocols is essential for safe operations

- Industry resilience: Heat press finishing remains a cornerstone of screen printing despite market challenges and technological changes

The Phoenix printing market’s $774.8 million value demonstrates significant opportunities for businesses that understand both technical excellence and local market dynamics. Companies succeeding in this environment combine advanced equipment, climate-appropriate techniques, and strategic positioning to serve diverse customer needs effectively.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.