Screen printing services in Gilbert, AZ transform blank apparel into powerful branding tools for businesses, schools, and community organizations throughout the East Valley. Whether you need custom uniforms for your team, promotional shirts for an upcoming event, or branded merchandise for your business, professional screen printing delivers vibrant, long-lasting designs that withstand Arizona’s intense heat and frequent washing. At Thrive Screen Printing, we combine state-of-the-art equipment with local expertise to produce high-quality custom apparel that meets the unique needs of Gilbert’s diverse community—from rapidly growing tech companies to established schools and sports leagues.

What Is Screen Printing and Why Is It Popular?

Screen printing pushes ink through mesh stencils onto fabric surfaces, creating bold designs with exceptional color vibrancy. This time-tested method dominates the custom apparel industry because each layer of ink bonds permanently with the garment fibers. Unlike digital printing methods that sit on top of fabric, screen-printed designs integrate into the material itself, ensuring superior durability even after hundreds of wash cycles.

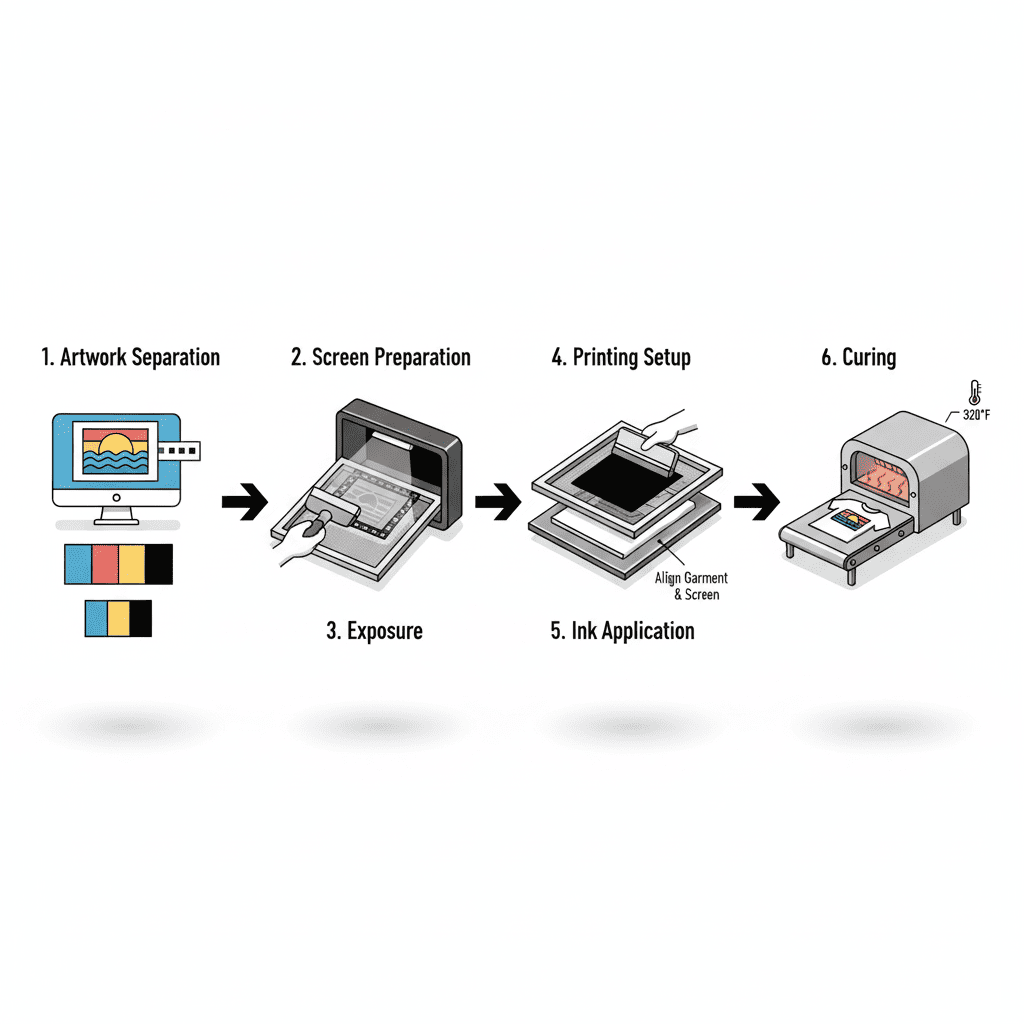

How the screen printing process works

The screen printing process begins when artwork transforms into separate screens for each color in your design. Our technicians coat each screen with light-sensitive emulsion, then expose it to UV light through your design template. This process creates a stencil where ink passes through open areas onto the garment below.

We position garments on printing pallets and align the first screen precisely over the fabric. Squeegees push plastisol or water-based ink through the mesh openings, depositing color directly onto the material. After printing each color layer, garments pass through a conveyor dryer at 320°F, which cures the ink and creates a permanent bond. This heat-curing process distinguishes screen printing from other methods, producing prints that maintain their integrity through years of wear.

Advantages over DTG, heat press & sublimation

Screen printing outperforms digital printing methods in several critical areas for bulk orders. Direct-to-garment (DTG) printing excels at photographic images but costs significantly more per unit and produces less vibrant colors on dark fabrics. Heat press vinyl creates raised designs that can peel or crack over time, especially in Gilbert’s extreme summer temperatures that regularly exceed 110°F.

Sublimation printing only works on polyester fabrics and light colors, limiting garment options for businesses needing cotton uniforms or dark-colored apparel. Screen printing handles all fabric types effectively, from 100% cotton to performance blends, making it ideal for Gilbert organizations requiring versatile custom apparel solutions. The method also scales efficiently—while DTG costs remain constant per shirt, screen printing becomes increasingly cost-effective as order quantities grow.

Who Uses Screen Printing in Gilbert, AZ?

Gilbert’s rapid growth from agricultural town to tech hub creates diverse screen printing needs across multiple sectors. The town’s population surge—from 5,717 residents in 1980 to over 242,955 today according to Gilbert’s official demographics—drives demand for custom apparel that builds community identity and brand recognition.

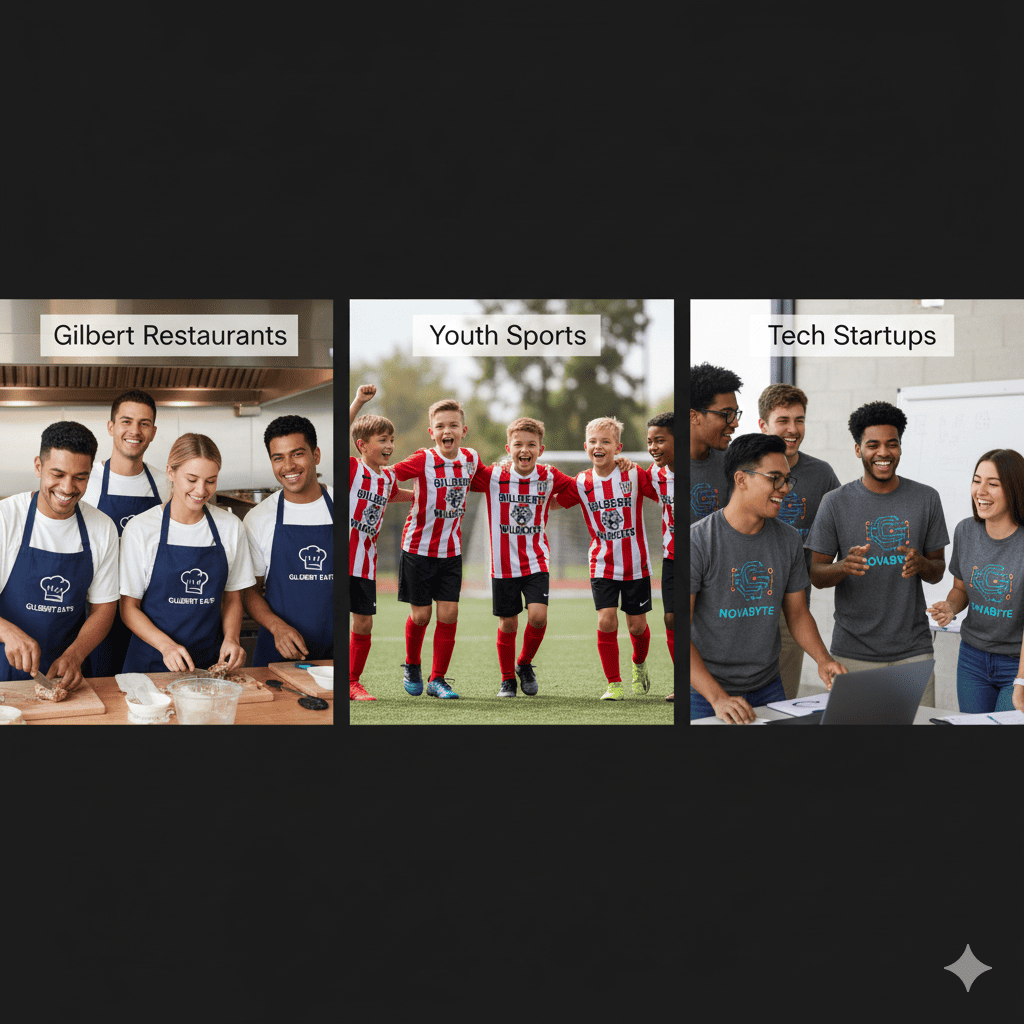

Local businesses & branding

Gilbert businesses leverage screen printing to establish professional brand presence in competitive markets. Technology companies in the Heritage District outfit employees with branded polos and t-shirts that project unified corporate identity during client meetings and trade shows. Restaurants along Gilbert Road commission custom aprons and staff shirts featuring their logos, creating memorable dining experiences that extend beyond food quality.

Construction companies and trade services throughout Gilbert rely on screen-printed work shirts for crew identification and professional appearance on job sites. These durable garments withstand daily wear while maintaining crisp logo reproduction, essential for businesses where appearance impacts customer trust. Local real estate agencies order branded apparel for open houses and community events, using custom shirts as walking advertisements throughout Gilbert’s neighborhoods.

Clubs, schools & sports teams

Gilbert’s 40+ public schools generate substantial screen printing demand for spirit wear, athletic uniforms, and fundraising merchandise. Highland High School Hawk pride translates into thousands of custom shirts annually for students, parents, and alumni. Youth sports leagues including Gilbert Little League and Desert Edge Baseball order team jerseys and practice gear that withstand Arizona’s extended playing seasons.

Community organizations like the Gilbert Rotary Club and Chamber of Commerce use screen-printed polos for member events and volunteer activities. Dance studios and martial arts schools throughout Gilbert commission custom apparel for recitals, competitions, and belt ceremonies. These orders often require quick turnaround times aligned with event schedules, making local screen printing services essential for meeting deadlines.

Event organizers & fundraisers

Gilbert’s year-round event calendar creates consistent demand for commemorative and promotional apparel. The Gilbert Days Parade requires thousands of volunteer and participant shirts. Local 5K races, charity walks, and festivals commission custom t-shirts that serve as both event souvenirs and fundraising vehicles.

Churches and nonprofit organizations maximize fundraising potential through screen-printed merchandise sales. Corporate sponsors value prominent logo placement on event shirts, creating advertising opportunities that extend far beyond event dates as participants continue wearing their shirts throughout Gilbert.

What Products Can You Customize with Screen Printing?

Screen printing versatility extends beyond basic t-shirts to encompass diverse product categories meeting various organizational needs. Our Phoenix facility maintains extensive inventory options ensuring quick fulfillment for time-sensitive projects while accommodating specific brand requirements according to Thrive Screen Printing.

T-shirts, polos, hoodies

Cotton t-shirts remain the most popular screen printing canvas, offering comfort and breathability essential for Arizona’s climate. We stock options ranging from basic 5.3oz cotton to premium ring-spun varieties that provide softer hand-feel and better print surfaces. Moisture-wicking performance shirts suit Gilbert’s active lifestyle, particularly for outdoor workers and athletic teams requiring technical fabrics.

Polo shirts elevate professional appearance for business casual environments common in Gilbert’s corporate parks. Screen printing on polos requires specialized techniques to navigate button plackets and collar seams while maintaining design integrity. Hoodies provide year-round utility in Gilbert’s climate, where morning temperatures can dip below 40°F in winter months before climbing to 70°F by afternoon. Full-zip and pullover styles accommodate different design placements and wearing preferences.

Tote bags, hats, and specialty items

Canvas tote bags offer eco-friendly promotional opportunities for Gilbert businesses embracing sustainability initiatives. Screen printing on bags requires adjusted pressure and specialized inks to ensure adhesion on woven surfaces. These reusable items provide extended brand exposure as customers carry them throughout farmers markets, grocery stores, and community events.

Hat decoration presents unique challenges requiring specialized equipment and techniques. While embroidery dominates cap decoration, screen printing excels on flat surfaces like trucker mesh panels and cotton bucket hats. Specialty items including koozies, rally towels, and drawstring bags expand promotional possibilities for Gilbert organizations seeking memorable giveaways. Each substrate requires specific ink formulations and curing parameters to ensure lasting adhesion.

What’s the Process for Ordering Custom Apparel?

Streamlined ordering processes reduce complexity for Gilbert customers managing multiple priorities. Our systematic approach ensures accurate production while maintaining flexibility for last-minute adjustments common with event-driven orders.

How to submit artwork

Vector artwork produces optimal screen printing results by maintaining crisp edges at any size. We accept Adobe Illustrator (.AI), EPS, and PDF files containing outlined fonts and embedded images. Customers without professional design software can submit high-resolution PNG files at 300 DPI minimum, though vector conversion may incur additional charges.

Our design team assists Gilbert businesses lacking print-ready artwork through consultation services. We convert logos from business cards, websites, or rough sketches into production-ready files. This process typically requires 24-48 hours depending on complexity and current workload. Pantone color matching ensures brand consistency across all printed materials, critical for businesses maintaining strict visual identity guidelines.

Choosing garment types & sizes

Gilbert’s demographic diversity requires comprehensive size ranges accommodating all community members. We maintain inventory from youth XS through adult 5XL in popular styles, with additional options available through special order. Fit varies significantly between brands—Gildan tends to run larger while Next Level offers more athletic cuts appealing to younger demographics.

Fabric selection impacts both comfort and print quality in Arizona’s climate. Lightweight 4.3oz shirts suit indoor events and layering, while standard 5.3-6oz options provide better opacity and structure. Tri-blend fabrics (50% polyester, 25% cotton, 25% rayon) offer premium softness but require adjusted printing techniques to prevent dye migration. Our team guides customers through options based on intended use, budget, and desired appearance.

Approvals & turnaround time

Digital mockups provide accurate visualization before production begins, eliminating costly surprises. We email proof images showing your design on selected garment colors. This approval stage allows adjustments to sizing, positioning, or color choices before screens enter production.

Standard turnaround time accommodates most Gilbert event schedules. Rush service is available for time-sensitive needs, though availability depends on current capacity. Peak seasons around graduation (May), back-to-school (August), and holiday seasons (November-December) may extend lead times. Planning orders ahead ensures stress-free fulfillment.

How Long Does Screen Printing Last on Apparel?

Professional screen printing creates permanent designs engineered to outlast the garments themselves. Properly cured plastisol inks maintain color vibrancy and adhesion through years of regular wear, making screen printing ideal for uniforms and favorite shirts worn weekly.

Care instructions to maximize durability

Proper garment care extends screen printing lifespan significantly beyond industry standards. Washing shirts inside-out in cold water prevents abrasion between printed surfaces and washing machine drums. Cold water also minimizes color bleeding from garment dyes that could discolor white ink areas. Machine drying on low heat prevents excessive shrinkage while maintaining ink flexibility.

Avoiding fabric softeners and bleach preserves both print quality and garment integrity. Fabric softeners contain silicone that builds up on printed areas, creating a waxy appearance over time. Bleach breaks down both fabric fibers and ink polymers, causing premature fading and deterioration. Line drying extends garment life further, though Gilbert’s intense summer sun requires shaded drying areas to prevent UV damage.

How Much Does Screen Printing Cost in Gilbert?

Screen printing pricing reflects multiple variables creating custom quotes for each project. Understanding cost factors helps customers optimize orders for budget efficiency while achieving desired quality outcomes.

Pricing factors: colors, order size, garment type

Color quantity drives screen printing costs more than any other design factor. Each color requires a separate screen, making single-color designs most economical. Screen costs amortize across larger orders.

Garment selection significantly impacts total project cost. Basic cotton t-shirts from economy brands are less expensive wholesale, while premium fashion brands are more costly per blank garment. Performance fabrics and specialty items command higher prices reflecting their technical properties and limited availability. Location complexity also affects pricing—large back prints cost more than standard left-chest logos due to increased ink usage and production time.

Bulk discounts and recurring orders

Volume pricing rewards organizations planning ahead for annual needs. Orders exceeding 144 pieces typically unlock additional price breaks beyond standard quantity discounts. A youth sports league ordering 300 shirts saves compared to placing multiple 50-shirt orders throughout the season.

Recurring order agreements benefit businesses requiring consistent uniform supplies. We maintain screen archives for repeat customers, eliminating setup charges on reorders. This arrangement particularly suits restaurants experiencing staff turnover or companies onboarding employees quarterly. Blanket purchase orders allow organizations to lock in pricing while drawing inventory as needed, providing budget predictability crucial for fiscal planning.

Why Choose Thrive Screen Printing in Gilbert?

Local expertise combined with technical capabilities positions Thrive Screen Printing as an East Valley custom apparel provider. Our deep community roots inform service approaches tailored to East Valley needs and expectations.

Local expertise and personalized service

Operating in the East Valley provides intimate understanding of local market dynamics and customer preferences. We recognize Highland High Hawks require different design aesthetics than Mesquite Mustangs, and that tech startups in the Heritage District seek modern, minimalist branding unlike traditional Main Street businesses. This localized knowledge streamlines design consultations and prevents cultural missteps common with out-of-state printing services.

Face-to-face consultations at our Phoenix facility enable real-time problem-solving impossible through online-only providers. Customers examine fabric samples, review color swatches, and approve physical samples before committing to full production runs. Our team members live in East Valley communities, shopping at the same stores and attending the same events as our customers. This personal investment translates into accountability and service quality exceeding transactional relationships according to Thrive Screen Printing.

State-of-the-art equipment and materials

Modern screen printing equipment ensures consistent quality across all order sizes. Our automatic presses maintain precise registration between colors, eliminating the slight misalignments common with manual printing.

Premium ink systems designed for Arizona conditions resist fading despite intense UV exposure. We utilize both plastisol and water-based inks depending on fabric requirements and customer preferences. Plastisol provides maximum opacity on dark garments while water-based inks create softer hand-feel preferred for fashion printing. Discharge printing capabilities allow printing on dark garments without the heavy ink deposit associated with traditional white underbase techniques.

Quick delivery and pickup options

Strategic location in the East Valley enables convenient customer access and efficient delivery routes. Orders ship via our delivery fleet throughout the East Valley. Local pickup remains available for customers preferring immediate possession or saving delivery charges on small orders.

Rush capabilities accommodate the dynamic business environment where opportunities arise quickly. Our production schedule maintains flexibility for legitimate urgent needs. A restaurant replacing stolen uniforms or team qualifying for unexpected tournament receives priority handling ensuring continuity of operations. This responsiveness builds lasting relationships extending beyond individual transactions.

Are There Compliance or Brand Guidelines to Consider?

Professional screen printing navigates complex intellectual property landscapes protecting both customers and printing companies from legal complications. Gilbert organizations must understand licensing requirements before reproducing protected designs or logos.

Licensing for schools & trademarks

Gilbert Public Schools maintains strict guidelines governing use of official logos and mascot imagery. Each school’s athletic director or activities coordinator must approve designs featuring school branding before production begins. This process protects schools’ trademark rights while ensuring consistent brand representation across all materials. Unauthorized reproduction of school logos can result in cease-and-desist orders and potential legal action.

Corporate logos require similar authorization from brand owners or marketing departments. Even internal company orders need proper approval chains to prevent outdated logo usage or incorrect color applications. Licensed properties including sports teams, entertainment franchises, and collegiate marks require official licensing agreements. We maintain relationships with major licensing agencies facilitating legitimate usage for customers seeking branded merchandise featuring favorite teams or characters.

Custom apparel and brand consistency

Brand consistency across multiple apparel items demands careful color matching and design scaling. Pantone Matching System (PMS) colors ensure precise reproduction regardless of substrate or printing method. However, ink opacity varies between light and dark garments, sometimes requiring adjusted color formulas to achieve visual consistency. Our color matching process includes physical samples demonstrating how specific inks appear on requested garment colors.

Design scaling presents challenges when artwork moves between different garment types. A logo optimized for left-chest placement may require adjustments when enlarged for full-back printing. Maintaining visual hierarchy and readability across size variations requires experienced design judgment. We provide scaled mockups showing how designs translate across product categories, preventing disappointment when small text becomes illegible or fine details disappear at reduced sizes.

How Does Gilbert’s Climate Affect Print Choices?

According to the Town of Gilbert, Gilbert experiences sunshine annually with summer temperatures regularly exceeding 111°F, creating unique considerations for custom apparel longevity and demanding specialized approaches to garment selection and ink systems.

Fabric choices for AZ heat

Lightweight, breathable fabrics prove essential for comfortable wear during Gilbert’s extended summer season. Cotton remains popular for its natural breathability, though 100% cotton shirts tend to shrink more than blended options. Polyester-cotton blends (typically 50/50 or 60/40) offer improved moisture management while reducing shrinkage below 5%. These blends also provide better color retention for the garment itself, preventing the faded appearance common with pure cotton after extended sun exposure.

Performance fabrics incorporating moisture-wicking technology suit active applications from youth sports to outdoor labor. These synthetic materials pull perspiration away from skin surfaces, improving comfort during physical activity. However, sublimated polyester fabrics require special ink considerations as traditional plastisol can inhibit moisture-wicking properties. Water-based and discharge inks maintain fabric breathability while providing necessary design durability.

Ink durability in sun and wash cycles

Arizona’s UV index regularly reaches extreme levels, accelerating ink degradation on improperly cured prints. Professional-grade plastisol inks formulated for outdoor exposure incorporate UV inhibitors extending color life significantly. These specialized formulations cost marginally more but prevent the rapid fading affecting budget inks within months of regular wear.

Proper curing temperatures ensure maximum wash fastness regardless of environmental conditions. While standard curing occurs at 320°F, we extend dwell time in our conveyor dryers ensuring complete ink polymer cross-linking. This process creates molecular bonds surviving repeated wash cycles without cracking or peeling.

What Do Customers Say About Thrive Screen Printing?

Customer experiences validate our commitment to quality and service excellence throughout the business community. Testimonials reflect consistent themes of reliability, quality, and local partnership extending beyond transactional relationships.

How Can You Get a Quote or Start Your Order?

Beginning your custom apparel project requires minimal information while our team handles technical details ensuring successful outcomes. Multiple contact methods accommodate different communication preferences and urgency levels.

Online form, phone, or in-person

Our online form at thrivescreenprinting.com captures essential project details. Upload artwork directly, specify quantities and garment preferences, then receive detailed pricing. The system calculates volume discounts automatically while flagging potential issues requiring clarification.

Phone consultations provide immediate answers for complex projects or tight deadlines. Our team discusses options in real-time, often providing ballpark pricing during initial conversations. This direct communication prevents misunderstandings common with email exchanges while building rapport essential for long-term partnerships.

In-person consultations at our Phoenix facility offer hands-on planning for significant orders. Examine fabric samples, review previous work examples, and finalize details face-to-face. We’re convenient to businesses throughout the East Valley communities. Walk-ins receive attention based on availability, though scheduled appointments ensure dedicated consultation time.

Get Expert Screen Printing in Gilbert Today

Transform your vision into professional custom apparel with Thrive Screen Printing’s proven expertise serving Gilbert businesses, schools, and organizations. Our combination of state-of-the-art equipment, premium materials suited for Arizona’s climate, and deep local knowledge ensures your screen-printed designs maintain vibrancy through years of wear and washing. Whether you need 12 shirts for a family reunion or 1,000 uniforms for your growing company, we deliver consistent quality with the personalized service only a local partner provides. Contact us today for a free quote and discover why Gilbert organizations trust Thrive Screen Printing for all their custom apparel needs—let’s bring your design to life!