How Do You Prepare Artwork for Screen Printing CMYK with Water-Based Inks?

If you’re looking to create vibrant, full-color prints with an eco-friendly approach, you’ve come to the right place. We understand that navigating CMYK screen printing with water-based inks can feel overwhelming with all the technical requirements and potential pitfalls. At Thrive Screen Printing, we’re here to guide you through every step of the process to ensure your designs translate beautifully onto fabric.

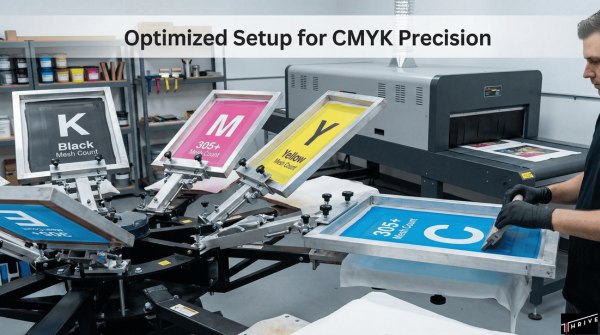

Preparing artwork for screen printing CMYK with water-based inks is a systematic process that involves color separation into four channels (Cyan, Magenta, Yellow, and Black), proper file setup at 300 DPI resolution or vector format, halftone implementation with specific angles and mesh counts, and careful consideration of ink characteristics that require longer curing times at 300-320°F compared to traditional plastisol inks.

TL;DR Summary

- Color Separation Essentials: Break down full-color images into four CMYK channels using Adobe Photoshop with manufacturer-specific color profiles (.csf files) and a 22.5° halftone angle to prevent moiré patterns.

- File Requirements: Use vector formats (AI, EPS, PDF) for scalability or ensure raster images are at least 300 DPI at final print size, as low-resolution files may require complete rebuilds.

- Water-Based Ink Advantages: Modern formulations offer soft, breathable prints with lower VOCs, improved opacity on dark garments, and enhanced compatibility with synthetic fabrics while maintaining eco-friendly properties.

- Technical Specifications: Use 305+ mesh count for CMYK printing, implement proper registration marks for multi-color alignment, and cure at 300-320°F for 2-3 minutes with forced air circulation.

- Troubleshooting Solutions: Prevent color shifts with calibrated monitors and Pantone guides, use retarders to prevent screen drying, and maintain 355-400 mesh count for ultra-fine detail work.

- Business Benefits: Achieve 50% profit margins with standard markup and up to 60-70% for complex jobs while offering eco-friendly appeal and improved wash resistance.

Quick Tip: Always perform test prints on sample fabric before starting production runs – this simple step can save hours of troubleshooting and ensure your water-based CMYK prints meet quality standards from the first pull.

As we dive deeper into the technical aspects of CMYK screen printing with water-based inks, you’ll discover how modern innovations have transformed what was once a challenging process into a reliable method for producing stunning, environmentally conscious prints that stand the test of time.

What Are the Essential Steps in Setting Up CMYK Artwork for Water-Based Screen Printing?

Setting up CMYK artwork for water-based screen printing requires precise color separation, proper file formatting, and strategic halftone implementation to achieve professional full-color results. Water-based inks demand specific technical considerations that differ from plastisol approaches, making artwork preparation the foundation for successful CMYK printing.

How Should You Separate Colors for CMYK Water-Based Printing?

Color separation breaks down full-color images into four constituent CMYK channels: Cyan, Magenta, Yellow, and Black, with each color printed on a separate screen. Adobe Photoshop serves as the industry standard software for precise color separation work. Manufacturer-specific color profiles (.csf files) from companies like Avient and Wilflex ensure accurate color reproduction throughout the printing process.

Screen angle placement prevents moiré patterns that can ruin print quality. A halftone angle of 22.5° provides optimal results for most water-based CMYK applications. Each color channel requires its own dedicated screen, creating four separate printing stations that layer sequentially to build the final image.

What Are the Ideal Resolution and File Formats for CMYK Art Prep?

Vector formats such as AI, EPS, and PDF are preferred for their scalability without quality loss during size adjustments. Raster images must maintain at least 300 DPI at the final print size to ensure crisp detail reproduction. Low-resolution files, screenshots, and social media images rarely meet professional standards and may require complete rebuild, according to screen printing expert Ian Browning.

File preparation impacts every aspect of the printing process. Insufficient resolution creates pixelated results that cannot be corrected during production. Vector artwork allows unlimited scaling while maintaining sharp edges and smooth curves essential for professional CMYK printing.

How Do You Use Halftones When Preparing CMYK Art for Water-Based Inks?

Halftones convert continuous tones into dots of varying sizes to recreate gradients and photographic detail. Lines Per Inch (LPI) calculations follow the formula: Mesh Count ÷ 5 for standard detail or Mesh Count ÷ 4 for higher detail requirements. Round dots represent the most common dot shape for halftone implementation due to their consistent printing characteristics.

Water-based inks require specific halftone considerations compared to plastisol alternatives. The ink’s absorption properties affect dot gain and final color density. Proper halftone setup ensures smooth gradations and prevents banding in photographic reproductions while maintaining the soft hand feel that water-based inks provide.

These essential artwork preparation steps establish the foundation for successful water-based CMYK printing, setting the stage for proper ink selection and printing technique implementation.

Why Is Ink Choice Important When Printing CMYK with Water-Based Inks?

Ink choice is crucial when printing CMYK with water-based inks because it directly affects print quality, fabric compatibility, color accuracy, and production efficiency. The right ink formulation ensures optimal adhesion to garments while maintaining the precise color reproduction required for four-color process printing. Modern water-based inks have evolved to address traditional limitations, offering improved opacity and durability that rivals plastisol while maintaining their eco-friendly advantages.

What Makes Water-Based Inks Different from Plastisol for CMYK Printing?

Water-based inks differ from plastisol inks in composition, application, and final print characteristics. Water-based inks contain water, pigments, and binders with significantly lower VOC emissions compared to plastisol’s PVC resin and plasticizers. These formulations produce soft, breathable prints that penetrate fabric fibers rather than sitting on top like plastisol’s thicker, rubber-like coating.

Modern water-based formulations offer enhanced features such as:

- Improved opacity for better coverage on various fabric colors

- Enhanced durability that withstands repeated washing

- Better performance on synthetic fabrics like polyester blends

- Reduced environmental impact through biodegradable options

Curing requirements also differ between the two ink types. Water-based inks require curing at 300-320°F for 2-3 minutes with forced air circulation to ensure complete water evaporation, while plastisol cures at 300-330°F for just 5-8 seconds.

Which Fabrics or Garments Are Best Suited for Water-Based CMYK Prints?

The best fabrics for water-based CMYK prints include natural fibers like 100% cotton and cotton blends, which provide excellent ink absorption and color vibrancy. New water-based formulations have expanded compatibility to include polyester and other synthetic fabrics, addressing previous limitations in synthetic printing.

Light-colored garments produce optimal results because they allow the true CMYK colors to show without interference. Water-based inks may require an underbase on dark garments to achieve proper opacity and prevent the fabric color from affecting the final print appearance. Ring-spun cotton offers the smoothest printing surface for detailed CMYK work.

How Does Ink Transparency Affect Color Reproduction in CMYK Screen Printing?

Ink transparency affects color reproduction by determining how underlying colors and fabric tones interact with printed inks. Traditional water-based inks were more transparent, making them challenging for dark garment printing, but modern formulations achieve bold and vibrant colors even on darker materials.

Good opacity is now standard for quality water-based inks, though an underbase may still be required on dark materials for optimal color accuracy. The four CMYK colors must maintain consistent transparency levels to ensure proper color mixing and avoid color shifts. Proper ink opacity prevents the garment color from bleeding through and affecting the final image appearance, which is essential for accurate color reproduction in process printing.

This section demonstrates how ink selection directly impacts the success of CMYK water-based printing projects. The next section will examine specific printing techniques that help achieve accurate CMYK color reproduction.

What Printing Techniques Help Achieve Accurate CMYK Color with Water-Based Inks?

Printing techniques that help achieve accurate CMYK color with water-based inks include proper mesh selection, precise registration methods, and controlled drying processes. These techniques ensure vibrant color reproduction and professional-quality results when screen printing with water-based CMYK inks.

How Do Mesh Counts and Screen Choices Impact CMYK Printing Results?

Mesh counts and screen choices directly impact CMYK printing results by controlling ink deposit and detail reproduction. Higher mesh counts deliver finer detail and smoother gradations essential for CMYK color accuracy.

For optimal water-based CMYK printing results:

- 305+ mesh count: Recommended standard for water-based CMYK printing

- 230-305 mesh range: Suitable for high-detail graphics and CMYK applications

- 110-160 mesh: Works for general purpose and less detailed designs

- 38-86 mesh: Reserved for specialty applications like glitter and shimmer inks

Higher mesh counts create smaller openings that deposit thinner ink layers, crucial for the transparency and color mixing required in CMYK printing. Lower mesh counts deposit heavier ink layers that can muddy color reproduction and reduce detail clarity.

What Factors Influence Registration Accuracy in Multi-Color Water-Based Prints?

Registration accuracy in multi-color water-based prints depends on precise alignment systems, proper screen preparation, and consistent printing conditions. Registration marks ensure accurate layering of the four CMYK colors across all print positions.

Key registration factors include:

- Registration marks: Essential for accurate layering of cyan, magenta, yellow, and black colors

- Screen alignment precision: Critical alignment of all four CMYK screens prevents color shifts

- Screen tension consistency: Proper tension prevents moiré patterns and registration drift

Precise alignment of the four CMYK screens creates the foundation for accurate color reproduction. Poor registration results in color bleeding, reduced sharpness, and visual distortion that compromises print quality.

How Do You Manage Drying and Curing with Water-Based CMYK Inks?

Managing drying and curing with water-based CMYK inks requires longer cure times and forced-air circulation to ensure complete water evaporation. Water-based inks need different curing parameters than plastisol inks.

Proper curing specifications:

- Temperature range: 300-320°F for optimal curing

- Time requirement: 2-3 minutes with forced air circulation

- Equipment need: Forced-air conveyor dryer essential for proper curing

- Evaporation factor: Longer curing time allows complete water evaporation

Water-based inks require longer curing time than plastisol to allow complete water evaporation from the ink film. A forced-air conveyor dryer provides the air movement necessary to remove moisture while maintaining consistent temperature across the print area.

These printing techniques work together to deliver the color accuracy and print quality that makes water-based CMYK printing a viable alternative to traditional plastisol methods. Proper mesh selection, registration control, and curing management ensure professional results that meet commercial printing standards.

What Common Problems Arise in CMYK Screen Printing with Water-Based Inks and How Can You Solve Them?

CMYK screen printing with water-based inks presents unique challenges that can compromise print quality and production efficiency. The most frequent issues include color shifts, premature ink drying, and loss of detail sharpness. Understanding these problems and implementing proven solutions ensures consistent, professional results in your water-based CMYK projects.

How Do You Prevent Color Shifts or Muddiness in Water-Based CMYK Prints?

Color shifts and muddiness occur when CMYK colors don’t reproduce accurately, creating dull or off-color prints. Water-based inks are particularly susceptible to color variation due to their interaction with fabric fibers and environmental factors.

Use manufacturer-specific color profiles (.csf files) from companies like Avient and Wilflex to ensure accurate color reproduction. These profiles compensate for ink characteristics and substrate interactions. Calibrate your monitor regularly using colorimeter tools to maintain consistent color matching between screen and print.

Implement a Pantone color guide system for precise color matching throughout production. Always perform test prints on sample fabric before starting production runs, as water-based inks can shift colors depending on fabric type and preparation.

Key Prevention Steps:

- Load manufacturer ICC profiles into design software

- Test print on identical substrate before production

- Use controlled lighting (5000K) for color evaluation

- Document successful color formulas for repeat orders

What Are the Best Practices for Preventing Ink Drying in Screens?

Ink drying in screens creates blockages that ruin print quality and halt production. Water-based inks dry faster than plastisol due to water evaporation, making screen management critical.

Add retarder to your ink formulation at 2-5% concentration to slow drying time without compromising curing properties. Keep screens flooded between prints by maintaining a thin layer of ink across the mesh. This prevents air exposure that accelerates drying.

Maintain proper humidity levels between 45-60% in your printing environment. Low humidity accelerates water evaporation, while excessive humidity can affect ink performance and curing.

Essential Drying Prevention Methods:

- Mix retarder at start of production run

- Flood screens immediately after each print stroke

- Use spray bottles for light misting during extended pauses

- Monitor ambient temperature and humidity continuously

How Are Detail and Image Sharpness Maintained in Fine CMYK Prints?

Detail loss in CMYK prints results from improper mesh selection, poor screen tension, or inadequate curing conditions. Water-based inks require precise handling to maintain the fine dot structures essential for CMYK reproduction.

Use 355-400 mesh count screens for fine detail work and UV applications where maximum sharpness is required. This high mesh count provides the precision needed for small halftone dots while maintaining adequate ink deposit.

Ensure proper screen tension using a tension meter to verify 25-35 Newtons across the mesh surface. Consistent tension prevents dot distortion and maintains sharp detail reproduction throughout the print run.

Monitor temperature and drying time carefully to prevent faded or cracked prints. Water-based inks require 300-320°F for 2-3 minutes with forced air circulation for complete curing without damaging fine details.

Detail Maintenance Protocol:

- Test mesh tension before each production run

- Use squeegee angles of 75-85 degrees for sharp prints

- Maintain consistent print speed and pressure

- Verify cure temperature with infrared thermometer

These troubleshooting strategies address the most common challenges in water-based CMYK printing, ensuring your prints maintain color accuracy, production efficiency, and sharp detail quality throughout your projects.

How Should You Approach Preparing Art and Screen Printing CMYK with Water-Based Inks with Thrive Screen Printing?

Working with Thrive Screen Printing for CMYK water-based ink projects combines expert preparation with proven commercial printing capabilities. The company has successfully integrated water-based printing into its commercial services while providing specialized guidance for CMYK color processes. Their expertise extends to handling water-based inks in Phoenix’s challenging heat conditions, ensuring consistent quality despite environmental factors.

Can Thrive Screen Printing Help With Art Preparation and Water-Based CMYK Projects?

Thrive Screen Printing can help with art preparation and water-based CMYK projects through their specialized commercial printing services. The company has successfully integrated water-based printing into its operations, offering clients both technical expertise and practical solutions for complex color work. Their services include guidance on the benefits of water-based inks and their specific applications in commercial printing environments.

The company’s experience with Phoenix heat conditions provides unique value for water-based ink projects. Water-based inks require careful temperature management during printing and curing, and Thrive’s local expertise ensures optimal results even in high-temperature environments where ink drying and screen management become critical factors.

What Are the Key Takeaways About Preparing Art and Screen Printing CMYK with Water-Based Inks We Covered?

The key takeaways about preparing art and screen printing CMYK with water-based inks include both technical and business considerations for successful projects. A 50% profit margin is achievable with keystone markup strategies, while complex CMYK jobs can command 60-70% profit margins due to their technical requirements and specialized expertise needed.

Water-based inks offer significant advantages for modern printing operations:

- Environmental benefits: Biodegradable formulations provide eco-friendly appeal for environmentally conscious clients

- Improved durability: Modern ink formulations show enhanced resistance to washing and fading compared to earlier water-based options

- Quality assurance: Wash testing protocols ensure prints are properly cured and maintain color integrity over time

The combination of technical precision in CMYK separation, proper mesh selection (305+ count), and careful curing at 300-320°F for 2-3 minutes with forced air creates prints that meet both aesthetic and durability standards. Success requires balancing color accuracy through manufacturer-specific profiles with practical considerations like ink transparency and fabric compatibility.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.