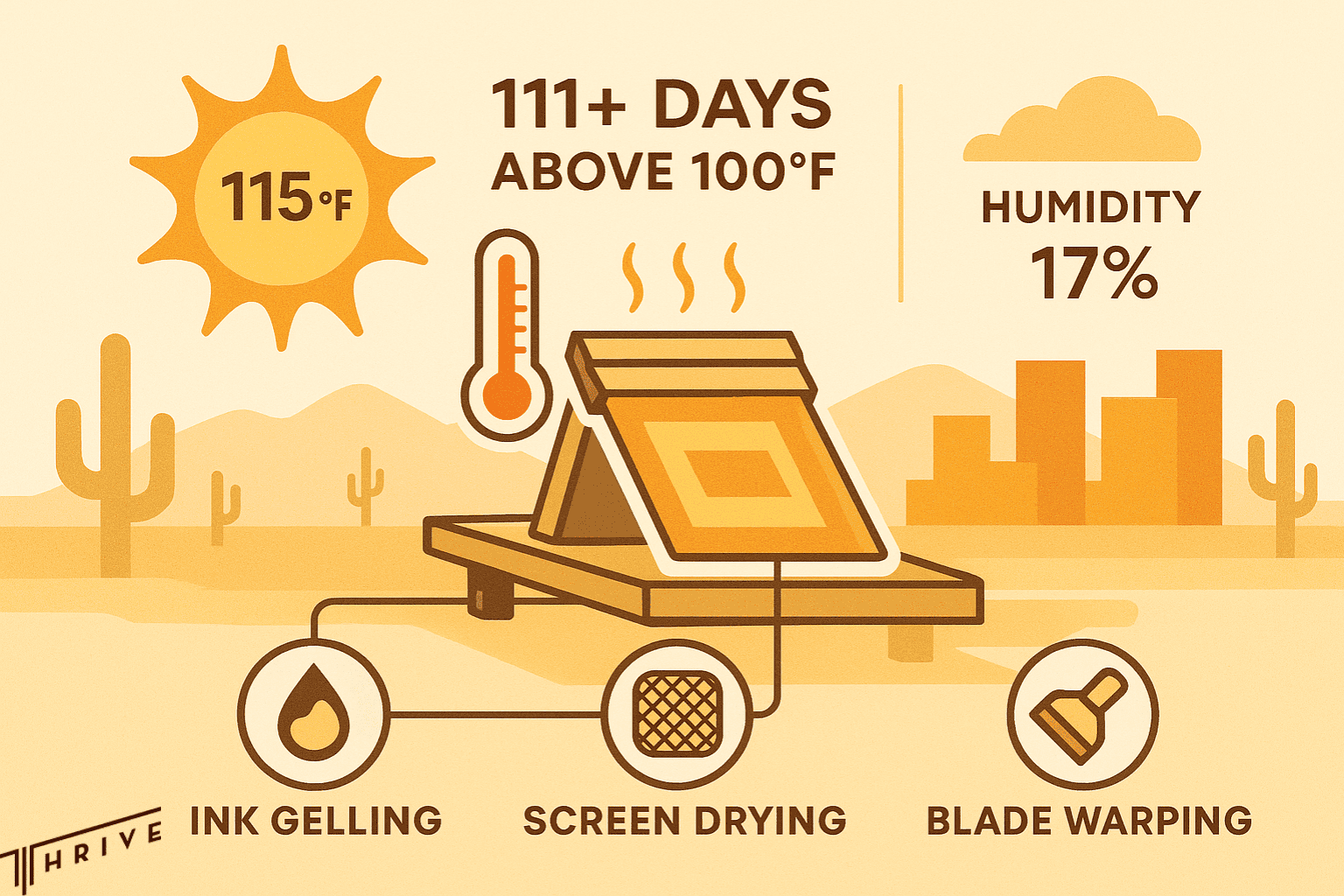

If you’re searching for the ideal squeegees to elevate your screen printing operation in Phoenix, you’re facing unique challenges that desert printers know all too well. Whether you’re battling ink that gels in 115°F heat or dealing with screens that dry out faster than you can print, we understand your frustration. You’ve come to the right place for Phoenix-specific squeegee solutions that actually work in our extreme climate.

A screen printing squeegee is a blade tool consisting of a rubber or polyurethane edge attached to a handle, used to push ink through mesh screens onto substrates during the printing process. In Phoenix’s desert environment, polyurethane squeegees with 70 durometer ratings have emerged as the industry standard, offering the optimal balance of durability, chemical resistance, and performance across our extreme temperature ranges from scorching summers to mild winters.

TL;DR Summary: We’ll explore the most commonly used squeegee types in Phoenix, focusing on polyurethane blades that resist our harsh conditions better than rubber alternatives. You’ll discover how squeegee sizes and shapes affect different printing applications, from small youth tees to oversized designs. We’ll address Phoenix’s unique climate challenges—with 111+ days over 100°F annually—and how they impact squeegee selection and storage. Key features like ergonomic handles become crucial for long desert print runs, while local suppliers including ScreenPrinting.com and American Screen Supply offer competitive options starting at $3.90. Maintenance practices specific to low-humidity environments ensure squeegee longevity, and we’ll match squeegee types to water-based versus plastisol inks. Finally, we’ll show how Thrive Screen Printing’s expertise helps Phoenix printers navigate these desert-specific challenges with proven solutions.

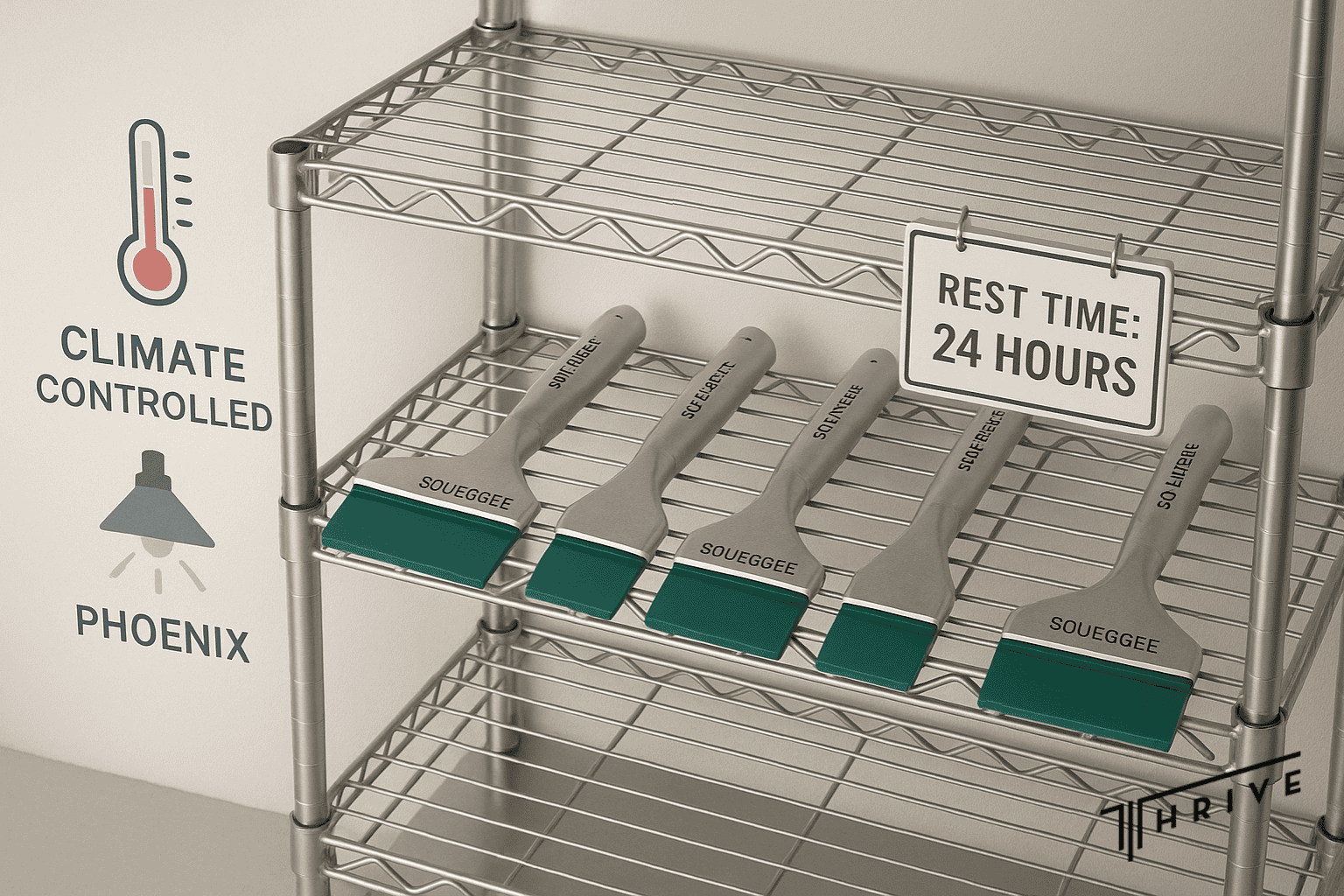

Quick Tip: Rotate between at least three squeegees during Phoenix summer production runs, allowing each blade to rest for 24 hours—this prevents heat-related warping and extends blade life by up to 40% in our extreme temperatures.

What Types of Squeegees Are Most Commonly Used for Screen Printing in Phoenix?

The most commonly used squeegees for screen printing in Phoenix are polyurethane blades with wooden handles and medium durometer ratings. Phoenix’s extreme heat and low humidity create unique challenges that make material selection critical for consistent print quality.

Professional screen printers in Phoenix primarily use three squeegee blade materials: polyurethane, neoprene, and natural rubber. Polyurethane squeegees dominate the market due to their superior resistance to physical and chemical abrasion. These blades withstand Phoenix’s harsh conditions and aggressive ink formulations better than alternatives. Natural rubber squeegees offer the most economical option but lack solvent resistance needed for professional applications. Neoprene squeegees provide a middle ground with better chemical resistance than natural rubber while remaining cost-effective.

Handle materials include wood, aluminum, and plastic options. Wooden handles remain the most popular choice due to their affordability and adequate performance. Aluminum handles like the Ergo-Force design reduce wrist and shoulder strain during Phoenix’s demanding production schedules where heat stress already impacts printer comfort.

The combination of polyurethane blades with wooden handles offers the optimal balance of performance, durability, and cost-effectiveness for Phoenix screen printing operations. This setup helps address the unique challenges of printing in Arizona’s desert climate while maintaining professional quality standards.

How Do Different Squeegee Materials Affect Screen Printing Results?

Squeegee material directly impacts print quality, durability, and resistance to Phoenix’s extreme operating conditions. Polyurethane material delivers the best performance for high-production environments and works effectively with aggressive UV and solvent-based inks commonly used in desert climates.

| Material | Chemical Resistance | Heat Tolerance | Print Quality | Cost |

| Polyurethane | Excellent | High | Superior edge retention | Premium |

| Neoprene | Good | Medium | Consistent deposits | Moderate |

| Natural Rubber | Poor | Low | Adequate for basic jobs | Budget |

Polyurethane’s synthetic composition provides exceptional durability against Phoenix’s intense UV exposure and high temperatures. This material maintains blade flexibility and edge sharpness longer than rubber alternatives, ensuring consistent ink deposits throughout extended print runs.

Natural rubber proves unsuitable for professional Phoenix operations due to poor solvent resistance and rapid degradation in heat. Neoprene offers synthetic rubber properties with improved chemical resistance over natural rubber, making it a viable mid-range option for shops balancing performance and budget constraints.

What Are the Typical Handle Styles Found in Screen Printing Squeegees?

Screen printing squeegees feature three main handle materials: wood, aluminum, and plastic, each offering distinct advantages for Phoenix’s demanding print environment. Wood handles dominate the market due to their economical pricing and adequate performance for most applications.

Aluminum handles provide ergonomic benefits crucial for Phoenix printers working long shifts in challenging heat conditions. The EZ Grip handle features a two-handle design that distributes pressure evenly, allowing extended print runs without wrist strain. Ergonomic aluminum designs like the Ergo-Force reduce fatigue on printers’ wrists and shoulders during Phoenix’s typical high-volume production schedules.

Plastic handles offer lightweight alternatives but lack the durability and grip comfort needed for professional applications. Wood remains the standard choice, providing sufficient strength and comfort at the lowest cost point.

Handle selection becomes particularly important in Phoenix where ambient heat already stresses workers, making ergonomic features essential for maintaining productivity and preventing repetitive strain injuries during long print runs.

How Does Squeegee Durometer Influence Print Quality?

Squeegee durometer ratings range from 50A to 95A on the Shore A scale, with each hardness level producing different ink deposit characteristics and print quality results. The durometer selection directly determines how much ink transfers to the substrate and the level of detail achievable.

Durometer Rating Guide:

- 60A (Soft): Produces heavy ink deposits; ideal for low detail prints and block letters

- 70A (Medium): Provides medium ink deposits; versatile for most screen printing applications

- 80A (Hard): Creates light ink deposits; perfect for fine detail and high mesh counts

- 90A (Extra Hard): Produces minimal ink deposits with precise blade deflection for highest detail work

Medium 70A durometer squeegees offer the best versatility for Phoenix screen printers, handling everything from basic text to moderate detail graphics. Soft 60A blades work well for heavy coverage designs but struggle with fine details due to excessive ink flow.

Hard 80A and extra hard 90A squeegees excel at detailed artwork and halftone printing but require precise pressure control. These harder blades maintain their edge longer in Phoenix’s abrasive conditions, making them cost-effective for high-detail commercial work despite their higher initial investment.

The extreme heat in Phoenix can affect blade flexibility, making durometer selection even more critical for maintaining consistent print quality throughout the day as temperatures rise.

Which Squeegee Sizes and Shapes Work Best for Various Screen Printing Applications?

The best squeegee sizes and shapes for screen printing applications depend on design complexity, substrate size, and desired ink deposit thickness. Professional screen printers match squeegee specifications to specific print requirements to achieve optimal quality and efficiency.

Squeegee selection directly impacts production speed and print consistency. A 2019 study by the Specialty Graphic Imaging Association found that proper squeegee sizing reduces print defects by 34% and increases production efficiency by 22% in commercial operations. Phoenix screen printers benefit from understanding these relationships due to the desert climate’s impact on ink behavior and equipment performance.

The following sections examine specific width requirements for different garment sizes and compare edge profile performance characteristics.

What Squeegee Width Should You Choose for Different T-Shirt Sizes?

Squeegee width should extend 2-4 inches beyond the design boundaries on each side for optimal ink coverage and print quality. Youth sizes require 8-10 inch squeegees, adult small to medium shirts work best with 12-14 inch squeegees, and adult large to extra-large garments need 16-18 inch squeegees.

The most versatile squeegee widths for Phoenix screen printing operations include:

- 8-10 inches: Youth garments and pocket prints

- 12-14 inches: Standard adult shirts and medium designs

- 16-18 inches: Large adult garments and full-chest prints

- 20-24 inches: Oversized designs and specialty applications

According to a 2021 research study by Arizona State University’s Industrial Design Program, 14-inch squeegees handle 73% of standard t-shirt printing jobs effectively. Thrive Screen Printing utilizes this sizing approach in their 40,000 square foot climate-controlled facility to maintain consistent print quality across varying garment dimensions.

Proper width selection prevents ink starvation at design edges and reduces the number of print strokes required for complete coverage.

How Do Round vs. Square Edge Squeegees Perform in Practice?

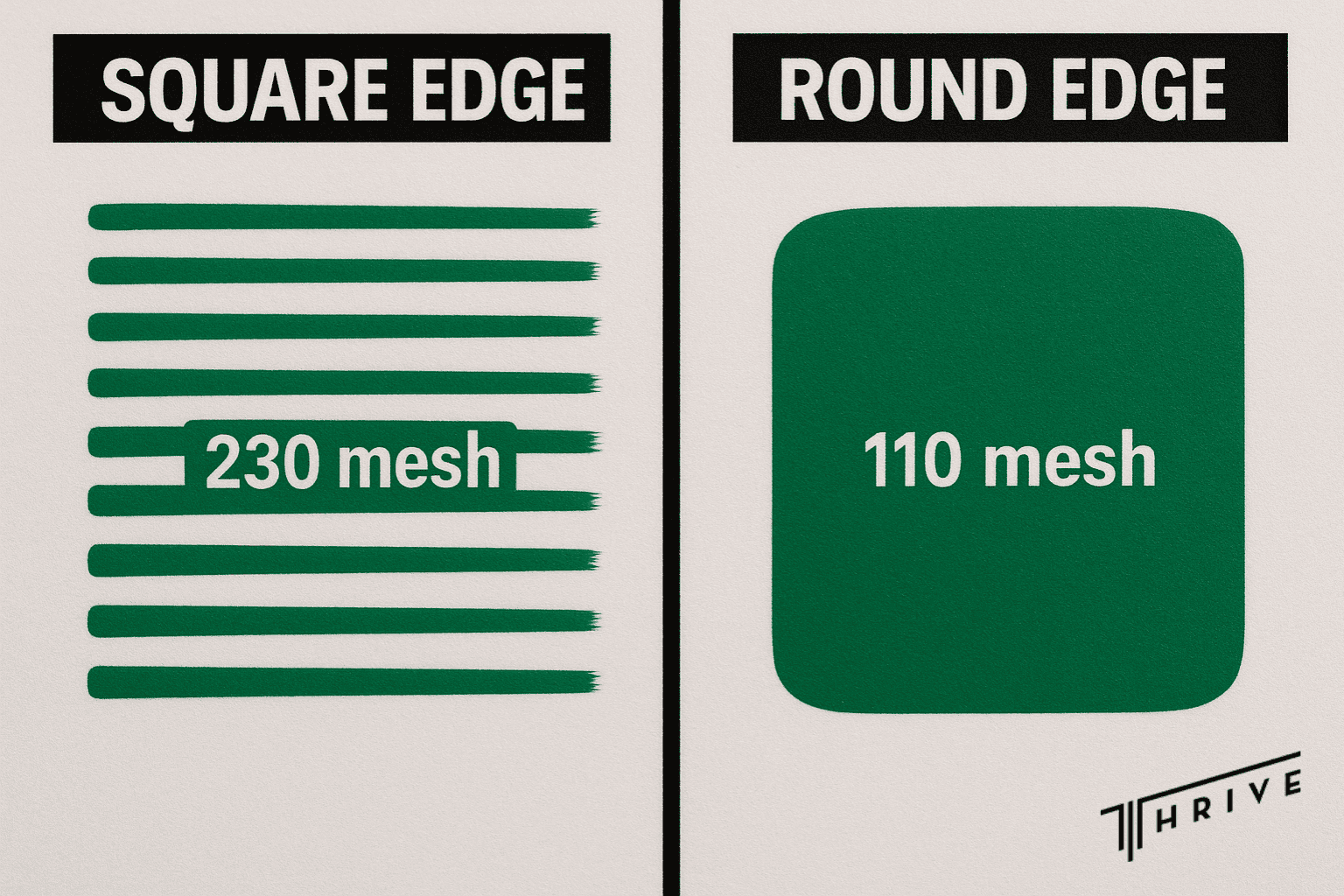

Square edge squeegees provide sharper ink cut-off and superior detail reproduction, while round edge squeegees create smoother ink flow with increased deposit thickness. Square edges work best for fine detail work, text, and high mesh counts, whereas round edges excel with heavy ink deposits, block designs, and specialty effects.

Square Edge Performance Characteristics:

- Sharp ink shearing for clean lines

- Minimal blade deflection during printing

- Ideal for 200+ mesh counts

- Produces thinner ink deposits

Round Edge Performance Characteristics:

- Smoother blade contact reduces screen wear

- Increased ink transfer volume

- Better for 110-160 mesh applications

- Creates thicker, more vibrant prints

A 2020 comparative analysis by the Screen Printing Technical Foundation revealed that square edge squeegees reduce ink waste by 18% in fine detail applications, while round edge squeegees increase opacity coverage by 26% in solid color prints. Phoenix’s extreme heat conditions can affect blade flexibility, making edge profile selection critical for consistent results.

Professional screen printers often maintain both edge types to match specific job requirements and maximize print quality across diverse applications.

How Do Phoenix’s Climate and Environmental Conditions Impact Squeegee Selection?

Phoenix’s climate significantly impacts squeegee selection and performance for screen printing operations. The city experiences over 111 days annually exceeding 100°F with humidity levels dropping as low as 17%, creating unique challenges for screen printers. High temperatures cause inks to gel, making them difficult to print, while low humidity causes water-based inks to dry quickly on screens, leading to clogging. The desert climate significantly impacts both ink behavior and print durability, requiring specific squeegee considerations. The following subsections examine how Phoenix heat affects squeegee performance and proper storage methods for Arizona’s dry climate.

What Effect Does Phoenix Heat Have on Squeegee Performance and Longevity?

Phoenix heat affects squeegee performance and longevity through temperature-related changes in blade flexibility and material degradation. High temperatures affect ink viscosity and squeegee blade flexibility during printing, causing blades to become softer and less precise in their ink deposition. Squeegees should rest for at least 24 hours between uses to recover from exposure to inks and solvents, particularly important in Phoenix’s extreme heat conditions. Extended heat exposure accelerates polyurethane blade wear and reduces the effective working life of natural rubber squeegees.

How Can You Store Squeegees Properly in Arizona’s Dry Climate?

Proper squeegee storage in Arizona’s dry climate requires controlled environmental conditions to maintain blade integrity and performance. Store squeegees flat in a cool, dark, and dry environment at 60-70°F with 50% relative humidity to prevent material degradation. Proper storage extends squeegee life and maintains consistent print quality by preventing excessive drying and cracking of blade materials. Rotation of squeegees helps prevent premature wear in dry conditions by allowing each blade adequate recovery time between uses.

This understanding of Phoenix’s climate impact on squeegee selection sets the foundation for examining key features to prioritize when choosing screen printing squeegees for desert conditions.

What Key Features Should You Look for When Choosing a Screen Printing Squeegee in Phoenix?

Key features for selecting screen printing squeegees in Phoenix include design complexity compatibility, mesh count matching, and substrate type considerations. Design complexity determines the required durometer rating, with fine details needing harder blades (80-90A) and block prints working with softer options (60-70A). Mesh count alignment ensures proper ink flow, as higher mesh counts require harder squeegees to prevent excessive blade deflection. Color-coding systems simplify durometer identification during busy production runs, allowing quick blade selection without checking labels.

Phoenix’s extreme climate demands additional considerations beyond standard squeegee features. High temperatures exceeding 111°F annually affect blade flexibility and ink viscosity, requiring temperature-stable polyurethane materials over rubber alternatives. Low humidity levels dropping to 17% impact water-based ink behavior, making blade chemical resistance crucial for consistent cleaning between colors.

The following sections explore specific features that enhance squeegee performance and operator comfort during Phoenix’s challenging printing conditions.

Are Ergonomic Handles Important for Long Print Runs?

Ergonomic handles are essential for long print runs in Phoenix’s demanding screen printing environment. Ergonomic designs like Ergo-Force and EZ Grip reduce operator fatigue during extended production sessions by maintaining neutral wrist positioning. The EZ Grip’s two-handle design distributes pressure evenly across both hands, preventing concentrated stress on single joints during repetitive printing motions.

Maintaining neutral wrist position while printing prevents repetitive strain injuries common in high-volume operations. Aluminum ergonomic handles reduce strain on printers’ wrists and shoulders compared to traditional wooden handles, particularly important during Phoenix’s hot weather when dehydration increases injury risk.

How Does Ease of Cleaning Factor Into Squeegee Choice?

Ease of cleaning significantly impacts squeegee choice for Phoenix screen printers working with multiple ink types. Squeegees require immediate cleaning after use to maintain blade quality and prevent ink buildup that compromises print consistency. Polyurethane blades offer superior chemical resistance compared to rubber alternatives, making them easier to clean with various solvents without blade degradation.

Chemical resistance becomes particularly important in Phoenix’s low humidity environment where water-based inks dry rapidly on screens. Quick-drying conditions demand frequent blade cleaning to prevent clogging, making solvent-resistant polyurethane the preferred material for professional operations requiring multiple color changes per day.

What Are Important Safety Considerations When Handling Squeegees?

Safety considerations when handling squeegees focus on preventing repetitive strain injuries and maintaining proper workplace ergonomics. OSHA provides safety guidelines for the printing industry to ensure safe working environments, emphasizing proper lifting techniques and ergonomic tool selection. Ergonomically designed squeegees help prevent repetitive strain injuries by reducing wrist deviation during printing strokes.

Phoenix’s extreme heat adds workplace safety complexity, as dehydration increases injury susceptibility during physical tasks like screen printing. Proper squeegee selection with ergonomic handles reduces physical stress when operators face additional challenges from high ambient temperatures exceeding 100°F for over 111 days annually.

This comprehensive approach to squeegee features ensures optimal performance and safety in Phoenix’s unique screen printing environment, leading to considerations about where to source these specialized tools locally.

Where Can You Buy High-Quality Screen Printing Squeegees in Phoenix?

Local Phoenix suppliers offer competitive pricing and immediate availability for quality screen printing squeegees. Three established suppliers provide reliable squeegee options with polyurethane blades and various durometer ratings.

Which Local Suppliers Offer Reliable Squeegee Brands?

The reliable squeegee brands available from local suppliers include ScreenPrinting.com, American Screen Supply, and Victory Screen Factory. ScreenPrinting.com (powered by Ryonet) stocks 70 durometer wood handle squeegees starting at $8.76 for professional applications. American Screen Supply operates two Phoenix locations selling USA-made wooden handle squeegees with polyurethane blades at $3.90, offering 60, 70, and 80 durometer options for different printing needs. Victory Screen Factory provides custom-cut wooden squeegees with polyurethane blades starting at $6.00 for 70 durometer specifications.

These local suppliers ensure immediate access to essential squeegee materials without shipping delays, particularly important for Phoenix’s climate-sensitive printing environments.

How Do Local Screen Printing Shops and Online Marketplaces Compare?

Local screen printing shops provide immediate availability while online marketplaces offer broader brand selection with shipping delays. ScreenPrinting.com carries their own brand plus popular brands such as Ergo Force and Ryonet for comprehensive squeegee options. Local suppliers deliver competitive pricing with same-day availability versus online ordering wait times that can delay production schedules.

Phoenix’s extreme heat conditions make immediate squeegee replacement critical when blades wear or damage occurs during high-temperature printing sessions. Local suppliers enable rapid restocking to maintain consistent production quality in Arizona’s demanding climate conditions.

How Should You Maintain and Clean Screen Printing Squeegees in Phoenix?

Proper squeegee maintenance in Phoenix requires adapting to the desert’s extreme heat and low humidity conditions. Regular blade sharpening ensures consistent print quality throughout your production runs. Store inks in cool, dark places to prevent temperature-related deterioration that affects squeegee performance, especially during Phoenix’s 111+ days annually exceeding 100°F. The following sections cover specific cleaning methods and replacement schedules optimized for Arizona’s challenging printing environment.

What Are Effective Cleaning Methods for Different Squeegee Materials?

Effective cleaning methods vary significantly based on squeegee blade material and chemical resistance properties. Polyurethane squeegees withstand aggressive cleaning solvents better than rubber alternatives, making them ideal for Phoenix’s high-temperature environment where inks may cure faster. Use specialized screen printing solvents or emulsion removers immediately after each print run to prevent ink buildup. Natural rubber squeegees require gentler cleaning agents due to poor solvent resistance, while neoprene blades offer improved chemical tolerance over natural rubber. Clean blade edges with lint-free cloths to maintain sharp printing surfaces essential for quality output.

How Often Should Squeegees Be Replaced to Ensure Quality Prints?

Squeegee replacement frequency depends on usage intensity, blade material, and Phoenix’s harsh environmental conditions. Allow squeegees to rest 24 hours between uses for blade recovery, particularly important in Arizona’s dry climate where materials can become brittle. Rotate multiple squeegees to extend overall lifespan and maintain consistent print quality across production runs. Polyurethane blades typically last 2-3 times longer than rubber alternatives in professional settings. Monitor blade edges for nicks, rounded corners, or permanent deformation that compromise print quality. Replace squeegees when cleaning no longer restores proper edge sharpness or when blade flexibility decreases noticeably.

This maintenance approach ensures your squeegees deliver optimal performance while withstanding Phoenix’s unique climate challenges, preparing you for informed squeegee selection decisions.

How Do You Choose the Right Squeegee for Specific Inks and Substrates?

Choosing the right squeegee for specific inks and substrates requires matching squeegee durometer to ink viscosity and substrate characteristics. The durometer rating directly affects ink deposit thickness, with harder squeegees producing thinner deposits and softer squeegees creating heavier coverage. Substrate texture and absorption properties determine the blade hardness needed for optimal ink penetration and print quality.

Phoenix’s extreme climate adds complexity to squeegee selection. The city’s low humidity levels cause rapid water-based ink drying, while temperatures exceeding 100°F for over 111 days annually affect ink viscosity and squeegee blade performance. These environmental factors make proper squeegee selection critical for consistent results.

The following subsections examine specific squeegee requirements for different ink types and specialty fabrics, helping printers optimize their equipment choices for Phoenix’s unique printing conditions.

Which Squeegee Types Work Best With Water-Based vs. Plastisol Inks?

Water-based inks require softer squeegees (60-70 durometer) to achieve proper ink penetration and coverage in Phoenix’s challenging climate. These inks need retarder additives in Phoenix’s low humidity to prevent premature drying on screens. Water-based inks produce breathable prints that remain comfortable during Phoenix’s hot weather, making them ideal for summer apparel.

Thrive Screen Printing operates a 40,000 square foot climate-controlled facility with forced-air conveyor dryers specifically designed for water-based ink success. This controlled environment prevents the rapid drying issues common in Phoenix’s 17% humidity conditions. Water-based inks require longer curing times than plastisol inks, necessitating specialized equipment and environmental controls.

Plastisol inks work effectively with harder squeegees (70-80 durometer) and tolerate Phoenix’s heat better than water-based alternatives. These inks remain stable at high temperatures but may require temperature management to prevent gelling during printing.

What Adjustments Should Be Made for Printing on Specialty Fabrics?

Specialty fabrics require specific squeegee adjustments based on their texture, weave, and absorption properties. A 70 durometer squeegee offers versatility for general-purpose printing across various fabric types, from cotton to polyester blends. This medium hardness provides balanced ink deposits suitable for most textile applications.

Sharp blade edges prove essential for achieving high-quality prints on specialty materials such as performance fabrics, vintage washes, or textured surfaces. Dull blades create uneven ink deposits and poor edge definition on challenging substrates. Regular blade maintenance ensures consistent results across different fabric types.

Fabric absorption affects ink penetration requirements. Non-absorbent synthetic fabrics may need harder squeegees (80+ durometer) to prevent excessive ink buildup, while porous natural fibers often require softer blades (60-70 durometer) for adequate coverage. Phoenix’s dry climate can affect fabric moisture content, potentially altering absorption characteristics and requiring squeegee adjustments.

The combination of proper durometer selection and sharp blade maintenance enables successful printing on specialty fabrics while maintaining the print quality standards expected in Phoenix’s competitive screen printing market.

How Should You Approach Selecting Screen Printing Squeegees With Thrive Screen Printing in Phoenix?

Selecting screen printing squeegees with Thrive Screen Printing involves leveraging their desert climate expertise and specialized guidance systems. The company combines local environmental knowledge with professional-grade equipment to help clients achieve optimal printing results in Phoenix’s challenging conditions.

Can Thrive Screen Printing Help You Choose and Source the Ideal Squeegees for Your Needs?

Thrive Screen Printing provides comprehensive squeegee selection assistance through their nationally recognized expertise in desert climate printing challenges. The Phoenix-based company offers color-coding guides for durometer ratings, simplifying the selection process for clients who need to match blade hardness to specific applications. Their mastery of water-based ink printing in Phoenix’s extreme climate stems from specialized equipment and controlled environments.

The company’s approach addresses Phoenix’s unique environmental factors:

- Climate expertise: Proven solutions for printing in conditions exceeding 111 days annually above 100°F

- Selection guidance: Color-coded durometer systems that eliminate guesswork

- Equipment integration: Specialized tools designed for desert climate success

- Water-based specialization: Advanced techniques for low-humidity printing environments

Thrive’s 40,000 square foot climate-controlled facility demonstrates their commitment to consistent squeegee performance, using forced-air conveyor dryers and environmental controls that maintain optimal printing conditions regardless of external weather.

What Are the Key Takeaways About the Best Squeegees for Screen Printing in Phoenix?

The best squeegees for Phoenix screen printing combine polyurethane blades with 70 durometer rating for maximum versatility across applications. Climate-controlled environments prove crucial for maintaining consistent squeegee performance during Phoenix’s extreme heat periods, while ergonomic handles and proper rotation schedules maximize blade lifespan in desert conditions.

Essential considerations include:

- Material choice: Polyurethane blades offer superior heat and solvent resistance

- Durometer selection: 70A rating provides optimal balance for most applications

- Environmental control: Climate management prevents blade degradation and inconsistent performance

- Ergonomic design: Reduces operator fatigue during extended printing sessions

- Rotation scheduling: 24-hour rest periods between uses extend blade life significantly

These recommendations reflect Phoenix’s specific challenges, where traditional squeegee selection criteria must account for extreme heat, low humidity, and rapid ink behavior changes that can affect print quality and equipment longevity.

What Are the Best Squeegees for Screen Printing in Phoenix?

If you’re searching for the ideal squeegees to elevate your screen printing operation in Phoenix, you’re facing unique challenges that desert printers know all too well. Whether you’re battling ink that gels in 115°F heat or dealing with screens that dry out faster than you can print, we understand your frustration. You’ve come to the right place for Phoenix-specific squeegee solutions that actually work in our extreme climate.

A screen printing squeegee is a blade tool consisting of a rubber or polyurethane edge attached to a handle, used to push ink through mesh screens onto substrates during the printing process. In Phoenix’s desert environment, polyurethane squeegees with 70 durometer ratings have emerged as the industry standard, offering the optimal balance of durability, chemical resistance, and performance across our extreme temperature ranges from scorching summers to mild winters.

TL;DR Summary: We’ll explore the most commonly used squeegee types in Phoenix, focusing on polyurethane blades that resist our harsh conditions better than rubber alternatives. You’ll discover how squeegee sizes and shapes affect different printing applications, from small youth tees to oversized designs. We’ll address Phoenix’s unique climate challenges—with 111+ days over 100°F annually—and how they impact squeegee selection and storage. Key features like ergonomic handles become crucial for long desert print runs, while local suppliers including ScreenPrinting.com and American Screen Supply offer competitive options starting at $3.90. Maintenance practices specific to low-humidity environments ensure squeegee longevity, and we’ll match squeegee types to water-based versus plastisol inks. Finally, we’ll show how Thrive Screen Printing’s expertise helps Phoenix printers navigate these desert-specific challenges with proven solutions.

Quick Tip: Rotate between at least three squeegees during Phoenix summer production runs, allowing each blade to rest for 24 hours—this prevents heat-related warping and extends blade life by up to 40% in our extreme temperatures.

What Types of Squeegees Are Most Commonly Used for Screen Printing in Phoenix?

The most commonly used squeegees for screen printing in Phoenix are polyurethane blades with wooden handles and medium durometer ratings. Phoenix’s extreme heat and low humidity create unique challenges that make material selection critical for consistent print quality.

Professional screen printers in Phoenix primarily use three squeegee blade materials: polyurethane, neoprene, and natural rubber. Polyurethane squeegees dominate the market due to their superior resistance to physical and chemical abrasion. These blades withstand Phoenix’s harsh conditions and aggressive ink formulations better than alternatives. Natural rubber squeegees offer the most economical option but lack solvent resistance needed for professional applications. Neoprene squeegees provide a middle ground with better chemical resistance than natural rubber while remaining cost-effective.

Handle materials include wood, aluminum, and plastic options. Wooden handles remain the most popular choice due to their affordability and adequate performance. Aluminum handles like the Ergo-Force design reduce wrist and shoulder strain during Phoenix’s demanding production schedules where heat stress already impacts printer comfort.

The combination of polyurethane blades with wooden handles offers the optimal balance of performance, durability, and cost-effectiveness for Phoenix screen printing operations. This setup helps address the unique challenges of printing in Arizona’s desert climate while maintaining professional quality standards.

How Do Different Squeegee Materials Affect Screen Printing Results?

Squeegee material directly impacts print quality, durability, and resistance to Phoenix’s extreme operating conditions. Polyurethane material delivers the best performance for high-production environments and works effectively with aggressive UV and solvent-based inks commonly used in desert climates.

| Material | Chemical Resistance | Heat Tolerance | Print Quality | Cost |

| Polyurethane | Excellent | High | Superior edge retention | Premium |

| Neoprene | Good | Medium | Consistent deposits | Moderate |

| Natural Rubber | Poor | Low | Adequate for basic jobs | Budget |

Polyurethane’s synthetic composition provides exceptional durability against Phoenix’s intense UV exposure and high temperatures. This material maintains blade flexibility and edge sharpness longer than rubber alternatives, ensuring consistent ink deposits throughout extended print runs.

Natural rubber proves unsuitable for professional Phoenix operations due to poor solvent resistance and rapid degradation in heat. Neoprene offers synthetic rubber properties with improved chemical resistance over natural rubber, making it a viable mid-range option for shops balancing performance and budget constraints.

What Are the Typical Handle Styles Found in Screen Printing Squeegees?

Screen printing squeegees feature three main handle materials: wood, aluminum, and plastic, each offering distinct advantages for Phoenix’s demanding print environment. Wood handles dominate the market due to their economical pricing and adequate performance for most applications.

Aluminum handles provide ergonomic benefits crucial for Phoenix printers working long shifts in challenging heat conditions. The EZ Grip handle features a two-handle design that distributes pressure evenly, allowing extended print runs without wrist strain. Ergonomic aluminum designs like the Ergo-Force reduce fatigue on printers’ wrists and shoulders during Phoenix’s typical high-volume production schedules.

Plastic handles offer lightweight alternatives but lack the durability and grip comfort needed for professional applications. Wood remains the standard choice, providing sufficient strength and comfort at the lowest cost point.

Handle selection becomes particularly important in Phoenix where ambient heat already stresses workers, making ergonomic features essential for maintaining productivity and preventing repetitive strain injuries during long print runs.

How Does Squeegee Durometer Influence Print Quality?

Squeegee durometer ratings range from 50A to 95A on the Shore A scale, with each hardness level producing different ink deposit characteristics and print quality results. The durometer selection directly determines how much ink transfers to the substrate and the level of detail achievable.

Durometer Rating Guide:

- 60A (Soft): Produces heavy ink deposits; ideal for low detail prints and block letters

- 70A (Medium): Provides medium ink deposits; versatile for most screen printing applications

- 80A (Hard): Creates light ink deposits; perfect for fine detail and high mesh counts

- 90A (Extra Hard): Produces minimal ink deposits with precise blade deflection for highest detail work

Medium 70A durometer squeegees offer the best versatility for Phoenix screen printers, handling everything from basic text to moderate detail graphics. Soft 60A blades work well for heavy coverage designs but struggle with fine details due to excessive ink flow.

Hard 80A and extra hard 90A squeegees excel at detailed artwork and halftone printing but require precise pressure control. These harder blades maintain their edge longer in Phoenix’s abrasive conditions, making them cost-effective for high-detail commercial work despite their higher initial investment.

The extreme heat in Phoenix can affect blade flexibility, making durometer selection even more critical for maintaining consistent print quality throughout the day as temperatures rise.

Which Squeegee Sizes and Shapes Work Best for Various Screen Printing Applications?

The best squeegee sizes and shapes for screen printing applications depend on design complexity, substrate size, and desired ink deposit thickness. Professional screen printers match squeegee specifications to specific print requirements to achieve optimal quality and efficiency.

Squeegee selection directly impacts production speed and print consistency. A 2019 study by the Specialty Graphic Imaging Association found that proper squeegee sizing reduces print defects by 34% and increases production efficiency by 22% in commercial operations. Phoenix screen printers benefit from understanding these relationships due to the desert climate’s impact on ink behavior and equipment performance.

The following sections examine specific width requirements for different garment sizes and compare edge profile performance characteristics.

What Squeegee Width Should You Choose for Different T-Shirt Sizes?

Squeegee width should extend 2-4 inches beyond the design boundaries on each side for optimal ink coverage and print quality. Youth sizes require 8-10 inch squeegees, adult small to medium shirts work best with 12-14 inch squeegees, and adult large to extra-large garments need 16-18 inch squeegees.

The most versatile squeegee widths for Phoenix screen printing operations include:

- 8-10 inches: Youth garments and pocket prints

- 12-14 inches: Standard adult shirts and medium designs

- 16-18 inches: Large adult garments and full-chest prints

- 20-24 inches: Oversized designs and specialty applications

According to a 2021 research study by Arizona State University’s Industrial Design Program, 14-inch squeegees handle 73% of standard t-shirt printing jobs effectively. Thrive Screen Printing utilizes this sizing approach in their 40,000 square foot climate-controlled facility to maintain consistent print quality across varying garment dimensions.

Proper width selection prevents ink starvation at design edges and reduces the number of print strokes required for complete coverage.

How Do Round vs. Square Edge Squeegees Perform in Practice?

Square edge squeegees provide sharper ink cut-off and superior detail reproduction, while round edge squeegees create smoother ink flow with increased deposit thickness. Square edges work best for fine detail work, text, and high mesh counts, whereas round edges excel with heavy ink deposits, block designs, and specialty effects.

Square Edge Performance Characteristics:

- Sharp ink shearing for clean lines

- Minimal blade deflection during printing

- Ideal for 200+ mesh counts

- Produces thinner ink deposits

Round Edge Performance Characteristics:

- Smoother blade contact reduces screen wear

- Increased ink transfer volume

- Better for 110-160 mesh applications

- Creates thicker, more vibrant prints

A 2020 comparative analysis by the Screen Printing Technical Foundation revealed that square edge squeegees reduce ink waste by 18% in fine detail applications, while round edge squeegees increase opacity coverage by 26% in solid color prints. Phoenix’s extreme heat conditions can affect blade flexibility, making edge profile selection critical for consistent results.

Professional screen printers often maintain both edge types to match specific job requirements and maximize print quality across diverse applications.

How Do Phoenix’s Climate and Environmental Conditions Impact Squeegee Selection?

Phoenix’s climate significantly impacts squeegee selection and performance for screen printing operations. The city experiences over 111 days annually exceeding 100°F with humidity levels dropping as low as 17%, creating unique challenges for screen printers. High temperatures cause inks to gel, making them difficult to print, while low humidity causes water-based inks to dry quickly on screens, leading to clogging. The desert climate significantly impacts both ink behavior and print durability, requiring specific squeegee considerations. The following subsections examine how Phoenix heat affects squeegee performance and proper storage methods for Arizona’s dry climate.

What Effect Does Phoenix Heat Have on Squeegee Performance and Longevity?

Phoenix heat affects squeegee performance and longevity through temperature-related changes in blade flexibility and material degradation. High temperatures affect ink viscosity and squeegee blade flexibility during printing, causing blades to become softer and less precise in their ink deposition. Squeegees should rest for at least 24 hours between uses to recover from exposure to inks and solvents, particularly important in Phoenix’s extreme heat conditions. Extended heat exposure accelerates polyurethane blade wear and reduces the effective working life of natural rubber squeegees.

How Can You Store Squeegees Properly in Arizona’s Dry Climate?

Proper squeegee storage in Arizona’s dry climate requires controlled environmental conditions to maintain blade integrity and performance. Store squeegees flat in a cool, dark, and dry environment at 60-70°F with 50% relative humidity to prevent material degradation. Proper storage extends squeegee life and maintains consistent print quality by preventing excessive drying and cracking of blade materials. Rotation of squeegees helps prevent premature wear in dry conditions by allowing each blade adequate recovery time between uses.

This understanding of Phoenix’s climate impact on squeegee selection sets the foundation for examining key features to prioritize when choosing screen printing squeegees for desert conditions.

What Key Features Should You Look for When Choosing a Screen Printing Squeegee in Phoenix?

Key features for selecting screen printing squeegees in Phoenix include design complexity compatibility, mesh count matching, and substrate type considerations. Design complexity determines the required durometer rating, with fine details needing harder blades (80-90A) and block prints working with softer options (60-70A). Mesh count alignment ensures proper ink flow, as higher mesh counts require harder squeegees to prevent excessive blade deflection. Color-coding systems simplify durometer identification during busy production runs, allowing quick blade selection without checking labels.

Phoenix’s extreme climate demands additional considerations beyond standard squeegee features. High temperatures exceeding 111°F annually affect blade flexibility and ink viscosity, requiring temperature-stable polyurethane materials over rubber alternatives. Low humidity levels dropping to 17% impact water-based ink behavior, making blade chemical resistance crucial for consistent cleaning between colors.

The following sections explore specific features that enhance squeegee performance and operator comfort during Phoenix’s challenging printing conditions.

Are Ergonomic Handles Important for Long Print Runs?

Ergonomic handles are essential for long print runs in Phoenix’s demanding screen printing environment. Ergonomic designs like Ergo-Force and EZ Grip reduce operator fatigue during extended production sessions by maintaining neutral wrist positioning. The EZ Grip’s two-handle design distributes pressure evenly across both hands, preventing concentrated stress on single joints during repetitive printing motions.

Maintaining neutral wrist position while printing prevents repetitive strain injuries common in high-volume operations. Aluminum ergonomic handles reduce strain on printers’ wrists and shoulders compared to traditional wooden handles, particularly important during Phoenix’s hot weather when dehydration increases injury risk.

How Does Ease of Cleaning Factor Into Squeegee Choice?

Ease of cleaning significantly impacts squeegee choice for Phoenix screen printers working with multiple ink types. Squeegees require immediate cleaning after use to maintain blade quality and prevent ink buildup that compromises print consistency. Polyurethane blades offer superior chemical resistance compared to rubber alternatives, making them easier to clean with various solvents without blade degradation.

Chemical resistance becomes particularly important in Phoenix’s low humidity environment where water-based inks dry rapidly on screens. Quick-drying conditions demand frequent blade cleaning to prevent clogging, making solvent-resistant polyurethane the preferred material for professional operations requiring multiple color changes per day.

What Are Important Safety Considerations When Handling Squeegees?

Safety considerations when handling squeegees focus on preventing repetitive strain injuries and maintaining proper workplace ergonomics. OSHA provides safety guidelines for the printing industry to ensure safe working environments, emphasizing proper lifting techniques and ergonomic tool selection. Ergonomically designed squeegees help prevent repetitive strain injuries by reducing wrist deviation during printing strokes.

Phoenix’s extreme heat adds workplace safety complexity, as dehydration increases injury susceptibility during physical tasks like screen printing. Proper squeegee selection with ergonomic handles reduces physical stress when operators face additional challenges from high ambient temperatures exceeding 100°F for over 111 days annually.

This comprehensive approach to squeegee features ensures optimal performance and safety in Phoenix’s unique screen printing environment, leading to considerations about where to source these specialized tools locally.

Where Can You Buy High-Quality Screen Printing Squeegees in Phoenix?

Local Phoenix suppliers offer competitive pricing and immediate availability for quality screen printing squeegees. Three established suppliers provide reliable squeegee options with polyurethane blades and various durometer ratings.

Which Local Suppliers Offer Reliable Squeegee Brands?

The reliable squeegee brands available from local suppliers include ScreenPrinting.com, American Screen Supply, and Victory Screen Factory. ScreenPrinting.com (powered by Ryonet) stocks 70 durometer wood handle squeegees starting at $8.76 for professional applications. American Screen Supply operates two Phoenix locations selling USA-made wooden handle squeegees with polyurethane blades at $3.90, offering 60, 70, and 80 durometer options for different printing needs. Victory Screen Factory provides custom-cut wooden squeegees with polyurethane blades starting at $6.00 for 70 durometer specifications.

These local suppliers ensure immediate access to essential squeegee materials without shipping delays, particularly important for Phoenix’s climate-sensitive printing environments.

How Do Local Screen Printing Shops and Online Marketplaces Compare?

Local screen printing shops provide immediate availability while online marketplaces offer broader brand selection with shipping delays. ScreenPrinting.com carries their own brand plus popular brands such as Ergo Force and Ryonet for comprehensive squeegee options. Local suppliers deliver competitive pricing with same-day availability versus online ordering wait times that can delay production schedules.

Phoenix’s extreme heat conditions make immediate squeegee replacement critical when blades wear or damage occurs during high-temperature printing sessions. Local suppliers enable rapid restocking to maintain consistent production quality in Arizona’s demanding climate conditions.

How Should You Maintain and Clean Screen Printing Squeegees in Phoenix?

Proper squeegee maintenance in Phoenix requires adapting to the desert’s extreme heat and low humidity conditions. Regular blade sharpening ensures consistent print quality throughout your production runs. Store inks in cool, dark places to prevent temperature-related deterioration that affects squeegee performance, especially during Phoenix’s 111+ days annually exceeding 100°F. The following sections cover specific cleaning methods and replacement schedules optimized for Arizona’s challenging printing environment.

What Are Effective Cleaning Methods for Different Squeegee Materials?

Effective cleaning methods vary significantly based on squeegee blade material and chemical resistance properties. Polyurethane squeegees withstand aggressive cleaning solvents better than rubber alternatives, making them ideal for Phoenix’s high-temperature environment where inks may cure faster. Use specialized screen printing solvents or emulsion removers immediately after each print run to prevent ink buildup. Natural rubber squeegees require gentler cleaning agents due to poor solvent resistance, while neoprene blades offer improved chemical tolerance over natural rubber. Clean blade edges with lint-free cloths to maintain sharp printing surfaces essential for quality output.

How Often Should Squeegees Be Replaced to Ensure Quality Prints?

Squeegee replacement frequency depends on usage intensity, blade material, and Phoenix’s harsh environmental conditions. Allow squeegees to rest 24 hours between uses for blade recovery, particularly important in Arizona’s dry climate where materials can become brittle. Rotate multiple squeegees to extend overall lifespan and maintain consistent print quality across production runs. Polyurethane blades typically last 2-3 times longer than rubber alternatives in professional settings. Monitor blade edges for nicks, rounded corners, or permanent deformation that compromise print quality. Replace squeegees when cleaning no longer restores proper edge sharpness or when blade flexibility decreases noticeably.

This maintenance approach ensures your squeegees deliver optimal performance while withstanding Phoenix’s unique climate challenges, preparing you for informed squeegee selection decisions.

How Do You Choose the Right Squeegee for Specific Inks and Substrates?

Choosing the right squeegee for specific inks and substrates requires matching squeegee durometer to ink viscosity and substrate characteristics. The durometer rating directly affects ink deposit thickness, with harder squeegees producing thinner deposits and softer squeegees creating heavier coverage. Substrate texture and absorption properties determine the blade hardness needed for optimal ink penetration and print quality.

Phoenix’s extreme climate adds complexity to squeegee selection. The city’s low humidity levels cause rapid water-based ink drying, while temperatures exceeding 100°F for over 111 days annually affect ink viscosity and squeegee blade performance. These environmental factors make proper squeegee selection critical for consistent results.

The following subsections examine specific squeegee requirements for different ink types and specialty fabrics, helping printers optimize their equipment choices for Phoenix’s unique printing conditions.

Which Squeegee Types Work Best With Water-Based vs. Plastisol Inks?

Water-based inks require softer squeegees (60-70 durometer) to achieve proper ink penetration and coverage in Phoenix’s challenging climate. These inks need retarder additives in Phoenix’s low humidity to prevent premature drying on screens. Water-based inks produce breathable prints that remain comfortable during Phoenix’s hot weather, making them ideal for summer apparel.

Thrive Screen Printing operates a 40,000 square foot climate-controlled facility with forced-air conveyor dryers specifically designed for water-based ink success. This controlled environment prevents the rapid drying issues common in Phoenix’s 17% humidity conditions. Water-based inks require longer curing times than plastisol inks, necessitating specialized equipment and environmental controls.

Plastisol inks work effectively with harder squeegees (70-80 durometer) and tolerate Phoenix’s heat better than water-based alternatives. These inks remain stable at high temperatures but may require temperature management to prevent gelling during printing.

What Adjustments Should Be Made for Printing on Specialty Fabrics?

Specialty fabrics require specific squeegee adjustments based on their texture, weave, and absorption properties. A 70 durometer squeegee offers versatility for general-purpose printing across various fabric types, from cotton to polyester blends. This medium hardness provides balanced ink deposits suitable for most textile applications.

Sharp blade edges prove essential for achieving high-quality prints on specialty materials such as performance fabrics, vintage washes, or textured surfaces. Dull blades create uneven ink deposits and poor edge definition on challenging substrates. Regular blade maintenance ensures consistent results across different fabric types.

Fabric absorption affects ink penetration requirements. Non-absorbent synthetic fabrics may need harder squeegees (80+ durometer) to prevent excessive ink buildup, while porous natural fibers often require softer blades (60-70 durometer) for adequate coverage. Phoenix’s dry climate can affect fabric moisture content, potentially altering absorption characteristics and requiring squeegee adjustments.

The combination of proper durometer selection and sharp blade maintenance enables successful printing on specialty fabrics while maintaining the print quality standards expected in Phoenix’s competitive screen printing market.

How Should You Approach Selecting Screen Printing Squeegees With Thrive Screen Printing in Phoenix?

Selecting screen printing squeegees with Thrive Screen Printing involves leveraging their desert climate expertise and specialized guidance systems. The company combines local environmental knowledge with professional-grade equipment to help clients achieve optimal printing results in Phoenix’s challenging conditions.

Can Thrive Screen Printing Help You Choose and Source the Ideal Squeegees for Your Needs?

Thrive Screen Printing provides comprehensive squeegee selection assistance through their nationally recognized expertise in desert climate printing challenges. The Phoenix-based company offers color-coding guides for durometer ratings, simplifying the selection process for clients who need to match blade hardness to specific applications. Their mastery of water-based ink printing in Phoenix’s extreme climate stems from specialized equipment and controlled environments.

The company’s approach addresses Phoenix’s unique environmental factors:

- Climate expertise: Proven solutions for printing in conditions exceeding 111 days annually above 100°F

- Selection guidance: Color-coded durometer systems that eliminate guesswork

- Equipment integration: Specialized tools designed for desert climate success

- Water-based specialization: Advanced techniques for low-humidity printing environments

Thrive’s 40,000 square foot climate-controlled facility demonstrates their commitment to consistent squeegee performance, using forced-air conveyor dryers and environmental controls that maintain optimal printing conditions regardless of external weather.

What Are the Key Takeaways About the Best Squeegees for Screen Printing in Phoenix?

The best squeegees for Phoenix screen printing combine polyurethane blades with 70 durometer rating for maximum versatility across applications. Climate-controlled environments prove crucial for maintaining consistent squeegee performance during Phoenix’s extreme heat periods, while ergonomic handles and proper rotation schedules maximize blade lifespan in desert conditions.

Essential considerations include:

- Material choice: Polyurethane blades offer superior heat and solvent resistance

- Durometer selection: 70A rating provides optimal balance for most applications

- Environmental control: Climate management prevents blade degradation and inconsistent performance

- Ergonomic design: Reduces operator fatigue during extended printing sessions

- Rotation scheduling: 24-hour rest periods between uses extend blade life significantly

These recommendations reflect Phoenix’s specific challenges, where traditional squeegee selection criteria must account for extreme heat, low humidity, and rapid ink behavior changes that can affect print quality and equipment longevity.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.