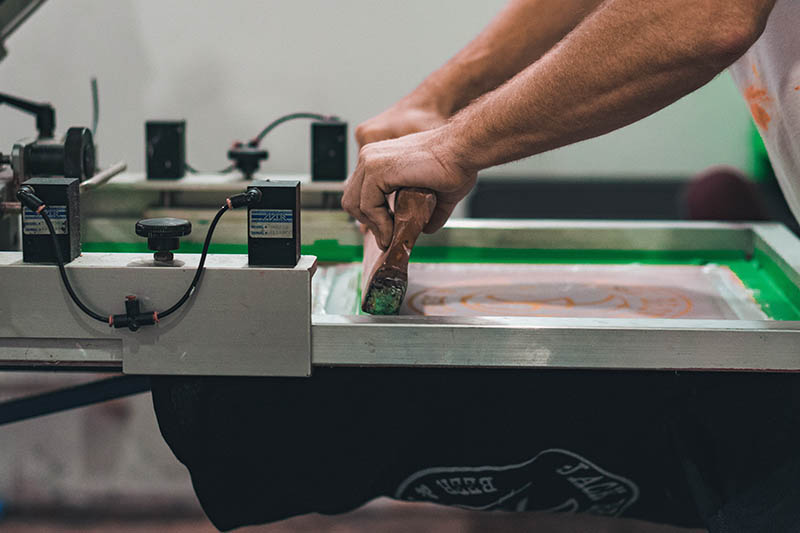

Screen printing, or you may have heard it called silkscreening, is when printers use a mesh screen to create custom designs by transferring ink to fabrics. There are several newer techniques on the market, but screen printing is the tried and true method for printing on clothing. Despite its popularity, there are still many things that you may need to learn about screen printing.

Hopefully, debunking these popular myths will help you make an informed decision about your custom clothing needs:

1. Screen Printing is an Outdated Technology

While screen printing has been around for a long time, it’s constantly evolving. The screen printing you see today is higher quality. Advances in technology enable printers to make incredibly clean and precise prints that were not capable of even a few years ago.

Technology is also allowing the process to be more eco-friendly. Screen printers can use non-PVC inks to avoid the potential harm to your health from these phthalate-based plasticizers. Using continuous ink systems and biodegradable post-production chemicals can prevent any environmental pollution and waste from going down the drain.

2. Local Screen Printers Are Expensive

This misconception stems from a quick internet search showing massive price tags for bulk orders. Many screen printers heavily discount bulk orders, bringing down the price per item, but it looks costly initially or if you only need a few shirts printed. Your local screen printer will scale the cost for your job, set appropriate limits for your unique project’s requirements, and give you an estimate for what you want.

An added benefit of working with a local company is that you’ll save on shipping costs by making direct purchases. You’ll be able to work with the company so they can understand your vision, design, and overall needs. This reduces the chance of implementation errors and reprinting requirements.

3. You Can Only Use Screen Printing for T-Shirts, Specifically White

Yes, screen printing is most famous for tops, such as t-shirts, polos, sweatshirts, tanks, and jackets. But depending on the design and material of the item you want it on, you can print on nearly anything, including pants, safety wear, and activewear. The unique accessories are endless: masks, bags, fleece blankets, and headwear, just to name a few.

And the garment you’re printing on doesn’t have to be white. Screen printing works on many materials. You can use screen printing on all colors, utilizing foil, metallics, glow-in-the-dark, and flock printing methods to create eye-catching colors and textures no matter the background color.

4. You Shouldn’t Print Your Own Design

If you are opting for a cheaper overseas operation, there is a lot of room for error if you are trying to get your own design printed. Poor quality prints give screen printing a bad reputation for looking cookie-cutter or not unique enough.

However, you don’t need to choose from a company’s catalog of recycled artwork either. The beauty of screen printing is that you can specify what you want, and professionals can help you optimize your design for the printing process. You can choose from every color, including metallic and foil printing, to make your design pop.

5. Screen Printed Designs Won’t Last

We have all had that favorite screen-printed shirt from camp, a sporting event, or a birthday party that started to crack, fade, flake, or peel off entirely. This degradation was partly due to older techniques, lack of technology, and maybe not the most careful printing company. Technology now allows for durable designs you can’t get rid of even if you try.

Additionally, fabric and printing materials are not all created equal. Made-in-China, dime-a-dozen, scratchy, screen-printed t-shirts are very different from what your local screen printing company will produce with a quality combed cotton tee.

6. You Can’t Rush Orders for Upcoming Events

Again, this misconception stems from shipping time and cost for international orders. You can find a quality screen-printing company that can implement your design flawlessly on a reasonably short timeline. If you are looking for branded material for a company retreat, volunteering or fundraiser event, or golf tournament, repeating your order with the same company can also cut down on the initial design conversations, expediting your overall order.

7. Screen Printing Only Works For Bulk Orders

While it is cheaper per item to print bulk orders, you can choose to get one custom item made or 10,000. Creating the printing template and setting up the machine is a significant portion of the fees. Printing multiple garment styles without resetting the printer and printing more garments per order will bring down your cost per item. As long as your graphic size can stay the same, you can have it printed on different articles, such as both adult and child-size shirts, aprons, or sweatshirts, which can also reduce your cost per item. Speak with your printing company about your pricing options.

Screen printing can meet your needs whether you want a custom present for your boss’s work anniversary, matching shirts for an upcoming retreat, or need one-of-a-kind swag for your next sales pitch. The time-tested, perfected methods are one of the most cost-effective options in the world for printing on textiles to bring your designs to life with long-lasting results.

Robert Fisher is the founder and CEO of Thrive Screen Printing and brings extensive experience in the screen printing and fulfillment industry.