Screen printing services in Scottsdale, AZ deliver vibrant, durable custom apparel for businesses, events, and organizations throughout the Valley of the Sun. This time-tested printing method transforms blank garments into powerful branding tools using mesh screens, specialized inks, and expert techniques. Scottsdale’s thriving tourism, hospitality, and retail sectors rely on professional screen printing to outfit staff, create memorable merchandise, and strengthen brand visibility. We specialize in producing high-quality printed apparel that withstands Arizona’s intense sun while maintaining crisp designs and vivid colors for years.

What Is Screen Printing and Why Does It Matter?

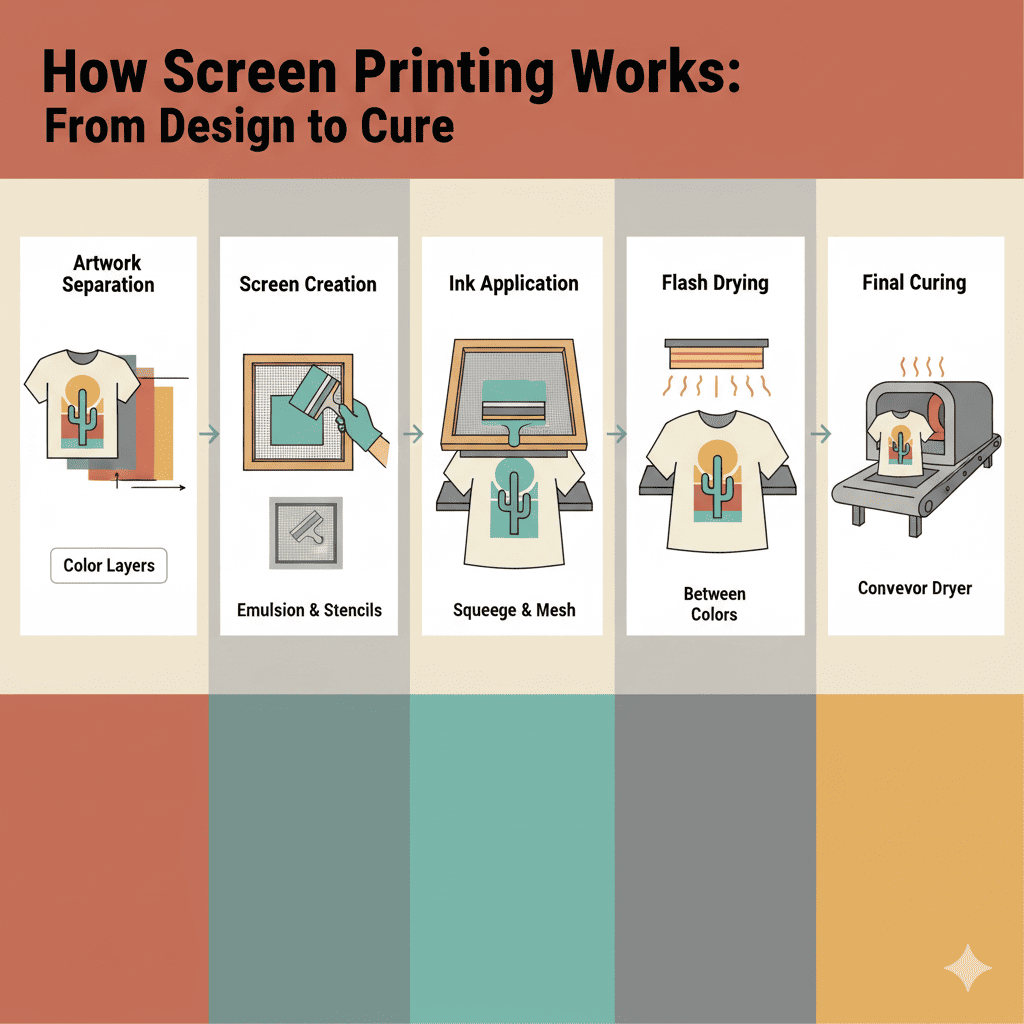

How screen printing works

Screen printing pushes ink through a mesh stencil onto fabric surfaces to create permanent designs. The process begins when artwork separates into individual color layers. Each color requires its own screen, which contains a stencil blocking ink from non-design areas. A squeegee forces ink through open mesh areas onto the garment below. Modern screen printing achieves detail levels as fine as 305 mesh count, enabling photorealistic prints on textiles, according to screen printing industry standards.

The printing sequence follows precise steps for consistency. First, screens align on a multi-color press using registration marks. Next, the printer loads garments onto platens beneath the screens. The squeegee applies controlled pressure while drawing ink across each screen. Between colors, a flash dryer partially cures the ink to prevent smearing. After all colors print, garments pass through a conveyor dryer reaching temperatures of 320°F, which fully cures plastisol inks for permanent adhesion.

Benefits over other printing methods

Screen printing outperforms digital methods in several key areas. The thick ink deposits create opacity that covers dark fabrics completely without requiring white underbase layers on every design. This ink thickness also produces a slightly raised texture that many customers prefer for its premium feel. Production speeds excel for large orders since each screen prints hundreds of items without quality degradation.

Durability sets screen printing apart from heat transfers and vinyl applications. Properly cured screen prints withstand 50+ wash cycles while maintaining color vibrancy and design integrity. The inks chemically bond with fabric fibers rather than sitting on the surface. Cost efficiency improves dramatically for orders exceeding 24 pieces because setup costs spread across more units.

Popular use cases for businesses and events

Scottsdale businesses leverage screen printing for employee uniforms, promotional giveaways, and retail merchandise. Restaurants outfit entire staffs in matching shirts featuring logos that remain visible after countless commercial launderings. Golf resorts create tournament shirts combining sponsor logos with event details. Real estate teams order matching polos that project professionalism during property showings.

Special events throughout Scottsdale rely on custom screen printing for participant shirts, volunteer identification, and commemorative merchandise. Local 5K races provide finisher shirts featuring route maps and sponsor recognition. Music festivals sell screen-printed merchandise generating significant revenue streams while spreading brand awareness.

Why Scottsdale Businesses Choose Screen Printing

Importance of visual branding in Arizona’s tourism and retail market

Scottsdale’s economy generates $3.7 billion annually from tourism according to the City of Scottsdale. Screen-printed apparel transforms employees into walking advertisements throughout Old Town, Fashion Square, and resort properties. Consistent branding across staff uniforms helps tourists identify businesses quickly in crowded entertainment districts.

The competitive retail landscape demands memorable brand touchpoints. Screen-printed merchandise creates lasting impressions that digital advertising cannot match. Customers wearing branded apparel become voluntary brand ambassadors, especially valuable in Scottsdale’s Instagram-friendly environments. Quality printing reflects positively on business reputations, while poor printing suggests corner-cutting that damages credibility.

Screen printing for hospitality staff, golf clubs, and resorts

Scottsdale’s 200+ golf courses require distinctive apparel for pro shop staff, marshals, and tournament volunteers. Screen printing produces professional polos and hats meeting dress code standards while promoting course brands. These garments endure daily wear, frequent washing, and constant sun exposure.

Hotels and restaurants choose screen printing for its consistency across large uniform orders. The Fairmont Scottsdale Princess orders matching shirts for entire departments, ensuring brand cohesion from valet attendants to poolside servers. Water-based inks provide breathability essential for outdoor workers in Arizona heat. Special coatings add UV protection, extending garment life under intense desert sun.

Merchandising opportunities at Scottsdale festivals & markets

The Scottsdale ArtWalk attracts thousands of visitors seeking unique souvenirs. Artists commission limited-edition screen-printed shirts featuring original designs that sell alongside traditional artwork. These wearable pieces generate additional revenue while promoting artists beyond gallery walls. Screen printing enables small batch production perfect for testing new designs without major inventory commitments.

Farmers markets and craft fairs throughout Scottsdale showcase local vendors who use branded apparel for team identification and merchandise sales. Merchandise sales often match or exceed product sales, making quality screen printing crucial for vendor success.

What Materials and Products Can Be Screen Printed?

Apparel options — t-shirts, hoodies, polos

Cotton t-shirts remain the most popular screen printing substrate due to excellent ink absorption and comfort. We print on various weights from lightweight 4.3oz fashion tees to heavy-duty 6.1oz work shirts. Polyester performance fabrics require special inks but produce moisture-wicking shirts ideal for Scottsdale’s active lifestyle. Cotton-polyester blends balance comfort with wrinkle resistance.

Hoodies gain popularity during Scottsdale’s mild winters and air-conditioned environments. Screen printing covers large hoodie areas effectively, including challenging positions like pockets and hoods. Polo shirts elevate brand presentations for client-facing employees. The textured pique fabric accepts screen printing well when properly prepared. Tank tops and sleeveless options suit outdoor workers and fitness-oriented businesses.

Specialty items — totes, hats, signage

Canvas tote bags showcase screen printing’s versatility beyond apparel. These reusable bags support Scottsdale’s sustainability initiatives while providing mobile advertising. The flat printing surface enables detailed designs impossible on curved garments. Grocery stores, bookshops, and boutiques order thousands of branded totes annually for customer purchases and promotional giveaways.

Hat printing requires specialized equipment and techniques. We screen print on flat-bill caps, visors, and bucket hats using modified presses. The structured crown provides stable printing surfaces for crisp logo reproduction. Non-textile items like coroplast signs, wooden plaques, and metal panels accept screen printing for indoor/outdoor applications. These durable prints withstand weather exposure better than vinyl graphics.

Fabric considerations for longevity and comfort

Fabric selection impacts both print quality and wearer satisfaction in Scottsdale’s climate. Natural fibers like cotton breathe well but may shrink without proper pre-treatment. We recommend pre-shrunk cotton for dimensional stability. Synthetic fabrics resist shrinking but require temperature-controlled curing to prevent scorching. Bamboo and modal blends offer eco-friendly alternatives with excellent moisture management.

Thread count affects print smoothness and durability. Higher thread counts produce smoother prints but may reduce breathability. Ring-spun cotton provides the softest hand-feel while maintaining print quality. For maximum durability, we suggest 100% cotton or 50/50 blends that balance comfort with easy care. Athletic mesh fabrics need special handling but produce lightweight uniforms perfect for outdoor summer events.

How Does the Screen Printing Process Work?

Step-by-step overview — from design to drying

Professional screen printing follows systematic procedures ensuring consistent results. Design preparation begins with vector artwork conversion for clean edges at any size. Our pre-press team separates colors into individual layers, adding registration marks for precise alignment. Screen preparation involves coating mesh with light-sensitive emulsion, then exposing designs using high-intensity UV lamps.

The printing sequence starts with screen registration on multi-station presses. We load garments onto pallets, ensuring smooth, wrinkle-free surfaces. Each color prints sequentially with flash-curing between applications. The squeegee angle, pressure, and speed remain constant for uniform ink deposits. Final curing occurs in conveyor dryers reaching optimal temperatures for complete ink polymerization.

Color separation and layering techniques

Complex designs require expert color separation maximizing visual impact while minimizing screen counts. Spot color separation assigns specific Pantone colors to design elements. Process separation creates photographic effects using CMYK screens plus white. Simulated process combines both techniques for vibrant prints on dark garments. Proper separation prevents color contamination and registration issues according to screen printing guidelines.

Underbase white layers provide opacity on dark fabrics, acting as primers for subsequent colors. Highlight whites add dimension to designs through strategic placement. Metallic and specialty inks layer differently than standard colors, requiring adjusted screen mesh counts. Halftone patterns create gradients and photographic effects within screen printing’s limitations. We determine optimal layering sequences based on design complexity and fabric color.

Standard vs. custom inks (plastisol, water-based)

Plastisol inks dominate commercial screen printing due to versatility and durability. These PVC-based inks cure at 320°F, creating flexible prints that stretch with fabric. Plastisol produces opaque coverage on any fabric color. The ink remains usable indefinitely when stored properly, reducing waste. Standard plastisol colors match Pantone specifications for brand consistency.

Water-based inks penetrate fabric fibers creating softer prints ideal for fashion applications. These inks produce vintage effects and work exceptionally on light-colored garments. Discharge inks remove fabric dye while depositing new colors, creating prints that feel like part of the shirt. High-density inks add dimensional effects for premium applications. Specialty additives create puff, shimmer, glow-in-the-dark, and thermochromic effects.

What Should You Look for in a Scottsdale Screen Printing Provider?

Local reviews and turnaround times

Scottsdale screen printers earn reputations through consistent performance and customer service. Google Business reviews reveal actual turnaround times versus advertised claims. We maintain 4.8+ star ratings through transparent communication and on-time delivery. Local references matter more than generic testimonials since they reflect real Scottsdale business experiences.

Production capacity determines realistic turnaround times for various order sizes. Our multi-station automatic presses print 500+ pieces hourly for large events. Standard orders complete within 5-7 business days from art approval. Rush services accommodate last-minute needs for conferences and tournaments. Holiday seasons require extended lead times due to increased demand across all Scottsdale printers.

Print quality, consistency, and ink options

Print quality varies dramatically between providers using different equipment and techniques. Professional shops maintain tight registration tolerances under 1/16 inch for multi-color designs. Consistent ink mixing ensures color matching across entire orders. We use computerized ink mixing systems achieving Pantone matches within Delta E 2.0 tolerance according to X-Rite color standards.

Equipment maintenance schedules impact print consistency throughout production runs. Our preventive maintenance program includes daily screen tension checks and monthly press calibrations. Quality control procedures catch defects before shipping. Available ink options should include eco-friendly alternatives for environmentally conscious clients. Specialty effects differentiate providers willing to tackle challenging projects.

Design support and mockup services

Professional design support transforms rough concepts into print-ready artwork. We provide vector conversion services for logos supplied in low-resolution formats. Design consultations identify potential printing challenges before production begins. Color recommendations consider fabric colors and ink opacity requirements. Size and placement guidance ensures designs complement garment styles.

Digital mockups show realistic representations before printing begins. Our mockup system displays actual garment colors with applied designs at proper proportions. Multiple design versions help clients visualize options without sample costs. Virtual samples reduce revision cycles and prevent costly mistakes. Final approval processes document client consent protecting both parties.

What Does Screen Printing Cost in Scottsdale?

Pricing factors — quantity, color count, garment type

Screen printing costs depend primarily on three variables working together. Order quantity provides the strongest influence since setup costs distribute across more pieces. A 12-piece order might cost $15-20 per shirt while 144 pieces reduce unit costs to $6-8.

Color counts directly impact pricing through additional screen setups and printing time. Single-color designs cost least while six-color prints command premium prices. Each color adds $15-25 in screen charges plus $0.50-1.00 per printed piece. Garment quality ranges from $2 basic tees to $15+ premium fashion brands. Specialty items like performance fabrics or oversized prints incur additional charges.

Bulk and group order discounts

Volume discounts reward larger orders through reduced per-unit pricing. Our pricing tiers typically break at 24, 72, 144, and 500+ pieces. Organizations combining orders achieve better pricing than individual departments ordering separately. Annual contracts for recurring uniform needs lock in preferential rates. We store screens for repeat orders, eliminating setup fees for exact reprints.

Group ordering platforms allow multiple participants to combine for bulk pricing while maintaining individual distribution. Youth sports leagues coordinate team orders achieving sponsor-subsidized pricing. Corporate accounts access net payment terms reducing upfront costs. Scottsdale Chamber of Commerce members receive exclusive pricing through our partnership program.

Comparing screen printing vs. direct-to-garment pricing

Direct-to-garment (DTG) printing suits small quantities with complex designs. DTG excels under 24 pieces where screen printing setup costs dominate. However, DTG costs remain constant regardless of quantity while screen printing costs decrease dramatically with volume. DTG prints fade faster than screen prints.

Screen printing economics improve beyond 24-piece minimums for simple designs. Multi-color designs reach cost parity around 72 pieces. Screen printing always wins for single-color designs at any quantity above 12. The tactile quality of screen printing justifies premium pricing for retail merchandise. We provide detailed quotes comparing both methods for informed decisions.

How Fast Can You Get Custom Printed Items?

Typical production turnaround times for Scottsdale orders

Standard production schedules accommodate most Scottsdale business needs within 7-10 business days. This timeline includes art preparation, screen creation, printing, and quality control. Simple reorders using existing screens complete in 3-5 days. Complex multi-location prints or special effects extend timelines to 10-14 days.

Seasonal demands affect production schedules throughout Scottsdale. Spring training creates rush orders for baseball-themed apparel. Fall golf tournaments generate uniform and merchandise needs. Holiday shopping seasons strain capacity from October through December. We maintain production calendars showing current capacity and realistic delivery dates.

Rush orders for events or launches

Emergency turnaround services accommodate last-minute Scottsdale events and product launches. Rush fees typically add 25-50% to standard pricing for 24-48 hour turnarounds. We maintain blank inventory of popular styles enabling same-day starts. Digital proof approvals expedite through text messaging for immediate responses. Dedicated rush production lines prevent delays from standard orders.

Event planners should communicate backup plans for truly urgent deadlines. Partial shipments allow events to proceed while remaining pieces finish. We coordinate with event venues for direct delivery when needed. Corporate launches often require confidentiality agreements protecting designs until reveal dates. Express shipping options ensure overnight delivery throughout metro Phoenix.

Shipping and pickup options

Local pickup from our Scottsdale facility saves shipping costs and transit time. We offer flexible pickup hours including early morning and evening slots. Large orders include delivery within Scottsdale city limits at no charge. Curbside pickup accommodates contactless transactions when preferred. Text notifications alert customers when orders are ready.

Shipping options range from ground service to overnight express delivery. We pack orders professionally preventing wrinkles during transit. Tracking information sends automatically upon shipment. Multi-location businesses appreciate our kit-packing services organizing garments by department or individual. International shipping supports Scottsdale’s global business connections with proper customs documentation.

Is Screen Printing Right for Your Business or Event?

When to choose screen printing vs. embroidery or DTG

Screen printing excels for bold graphics, large designs, and high-volume orders. The process works best on smooth, flat surfaces where ink can spread evenly. T-shirts, tanks, and tote bags represent ideal substrates. Events requiring 50+ matching shirts benefit from screen printing’s volume economics. Designs with solid colors produce vibrant results superior to other methods.

Embroidery suits professional applications requiring textured, upscale appearances. Polos, caps, and outerwear showcase embroidery’s dimensional quality. However, embroidery costs more and limits design complexity. DTG printing handles photographic images and unlimited colors without screens. Small batches under 24 pieces often favor DTG despite higher per-unit costs. We guide clients toward optimal methods for their specific needs.

ROI for branded apparel in Scottsdale’s service industries

Branded apparel generates measurable returns for Scottsdale service businesses through increased recognition and professionalism. 85% of recipients remember advertisers on promotional apparel according to the ASI Global Ad Impressions Study. Restaurant servers wearing branded shirts report higher tips than those in generic uniforms. Real estate agents distribute client closing gifts creating referral opportunities.

Cost-per-impression calculations favor screen-printed apparel over traditional advertising. A $10 screen-printed shirt worn weekly generates 1,000+ impressions annually. Digital ad campaigns achieving similar reach cost significantly more. Employee satisfaction improves when companies provide quality branded apparel. Retail merchandise sales offset uniform costs while spreading brand awareness.

Event planners: t-shirts as souvenirs and team IDs

Scottsdale event planners leverage custom t-shirts for participant identification and memorable takeaways. Color-coded shirts distinguish volunteers, staff, and VIP attendees at large gatherings. Participants keep shirts as souvenirs, extending event marketing beyond actual dates.

Registration packages including event shirts justify higher ticket prices. Sponsors appreciate logo placement on shirts worn by hundreds of participants. Social media photos featuring event shirts provide organic marketing content. We help planners design shirts balancing sponsor recognition with attractive designs participants want to wear. Youth events especially benefit from inclusive shirt sizing accommodating all participants.

Legal and Compliance Aspects to Consider

Sourcing blank garments ethically

Ethical sourcing meets increasing consumer demands for responsible business practices. We verify supplier compliance with fair labor standards through WRAP certification. Cotton sourcing considers environmental impacts including water usage and pesticide applications. Recycled polyester options reduce plastic waste while maintaining print quality. Scottsdale consumers increasingly request documentation of ethical sourcing.

Supply chain transparency extends through entire production processes. Our blank garment partners provide factory audit reports upon request. Living wage initiatives ensure fair compensation throughout manufacturing chains. Local sourcing reduces carbon footprints when available. We maintain relationships with suppliers demonstrating continuous improvement in sustainability practices.

Using trademarked logos correctly

Trademark compliance protects businesses from costly legal disputes. Screen printers must verify customers own rights to reproduced logos. Corporate brand guidelines dictate approved color specifications and minimum sizes. The U.S. Patent and Trademark Office requires proper symbol usage including ® and ™ designations. We maintain records documenting customer authorization for trademark reproduction.

Sports league logos require additional licensing through official suppliers. Schools and universities enforce strict logo usage policies. Parody designs must clearly indicate satirical intent avoiding confusion. We refuse orders violating intellectual property rights protecting both customers and our business. Design modifications ensure compliance while maintaining visual impact.

ADA-compliant apparel and uniforms

The Americans with Disabilities Act influences uniform requirements for public-facing employees. Screen-printed text must maintain adequate contrast ratios for visibility. Adaptive clothing options accommodate employees with mobility limitations. Tagless printing reduces sensory issues for sensitive individuals. We consult on ADA-friendly design choices supporting inclusive workplaces.

Uniform policies must allow reasonable accommodations without compromising brand standards. Alternative fabrics prevent allergic reactions while maintaining professional appearances. Extended size ranges ensure all employees access properly fitting uniforms. Scottsdale’s hospitality industry particularly benefits from inclusive uniform programs supporting diverse workforce needs.

How to Start Your Custom Screen Printing Order

Preparing your artwork

Professional artwork preparation ensures optimal printing results and faster production starts. Vector formats like Adobe Illustrator files scale infinitely without quality loss. We accept PDF, EPS, and AI files with fonts converted to outlines. Raster images require 300 DPI resolution at actual print size. Low-resolution web graphics need recreation for acceptable print quality.

Color specifications should include Pantone numbers for accurate matching. Design elements must maintain minimum line weights of 1 point for consistent reproduction. Reversed-out text requires special attention preventing fill-in during printing. We provide templates showing safe print areas for various garment styles. Free design consultations identify potential issues before production begins.

Choosing products and ink styles

Product selection balances budget, comfort, and durability requirements. We guide customers through fabric options considering end-use applications. Size distributions reflect typical demographic patterns preventing over-ordering extreme sizes. Sample garments help visualize final products before committing to large orders. Color coordination between garments and inks maximizes visual impact.

Ink selection affects both appearance and performance characteristics. Standard plastisol works for most applications providing durability and opacity. Fashion brands prefer water-based inks creating vintage aesthetics. Athletic applications benefit from stretch additives preventing cracking. Special effects like metallics or glow-in-the-dark create premium products. We recommend options based on design requirements and budget constraints.

Getting a free quote with Thrive Screen Printing

Our quoting process captures all necessary details ensuring accurate pricing without surprises. Online forms collect quantity, color counts, garment preferences, and timeline requirements. Uploaded artwork receives immediate review for potential issues. Quotes typically generate within 4 business hours during regular workdays. Rush quote requests receive priority handling for urgent needs.

Detailed quotes break down all cost components including setup fees and per-piece charges. Volume discount tiers show savings opportunities for larger orders. We highlight ways to optimize designs reducing costs without sacrificing quality. Quote validity periods allow time for approval processes and budget confirmations. Follow-up consultations clarify any questions ensuring complete understanding before proceeding.

Get Expert Screen Printing in Scottsdale Today

Transform your brand vision into reality with Thrive Screen Printing’s proven expertise serving Scottsdale businesses and events. Our combination of cutting-edge equipment, skilled craftspeople, and deep local market knowledge ensures your custom apparel exceeds expectations while meeting deadlines and budgets. Whether you need uniforms for your resort staff, merchandise for your festival, or promotional shirts for your real estate team, we deliver consistent quality that strengthens your brand presence throughout Scottsdale and beyond. Contact us today for a free consultation and discover why leading Scottsdale organizations trust Thrive Screen Printing for all their custom apparel needs.