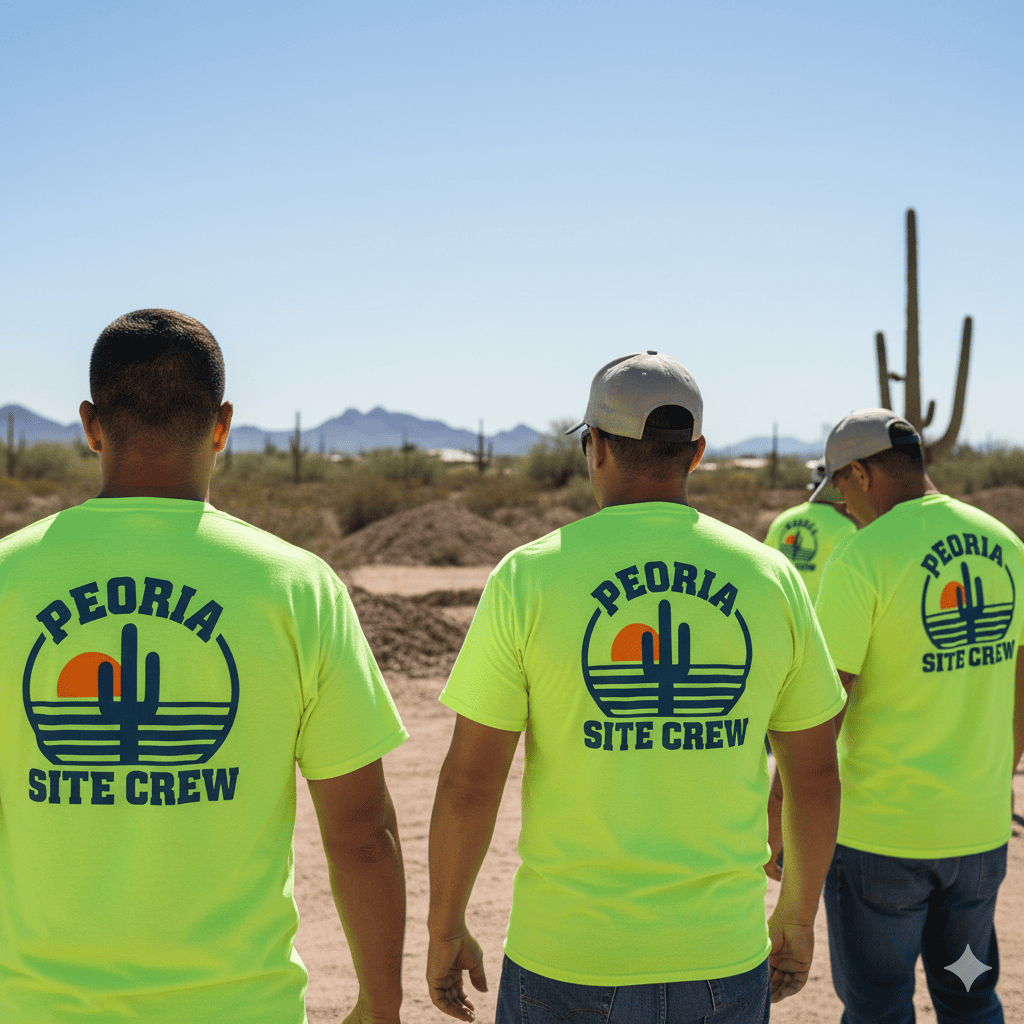

Screen printing services in Peoria, AZ deliver vibrant, durable designs for businesses, schools, and teams needing custom apparel that withstands Arizona’s intense sun and heat. Local businesses rely on professional screen printing for branded uniforms, promotional merchandise, and event apparel that maintains color integrity even after repeated washing and outdoor exposure. Thrive Screen Printing specializes in high-volume orders with fast turnaround times, serving Peoria’s active community with expertise in fabric selection and ink durability optimized for desert climates.

What Is Screen Printing and How Does It Work?

Screen printing pushes ink through mesh stencils onto fabric surfaces, creating bold, long-lasting designs ideal for bulk orders. The process involves creating separate screens for each color in your design, then pressing ink through those screens in precise registration to build the complete image. This technique excels at producing vibrant colors on dark fabrics and maintains consistency across hundreds or thousands of pieces.

How screen printing differs from DTG and heat press

Screen printing deposits thicker ink layers than direct-to-garment (DTG) printing, resulting in more vibrant colors and superior durability. While DTG printing applies water-based inks directly onto fabric like an inkjet printer, screen printing builds up plastisol or water-based inks that sit on top of the fabric fibers. Heat press methods transfer pre-printed designs using heat and pressure, but these vinyl or sublimation transfers crack or peel after repeated washes, whereas properly cured screen prints withstand over 100 wash cycles as per third-party testing.

Types of inks used for different fabric types

Plastisol inks remain the industry standard for cotton and cotton-blend fabrics, offering opacity and color vibrancy unmatched by other methods. Water-based inks penetrate fabric fibers for a softer hand feel, making them ideal for fashion tees and lightweight athletic wear. Specialty inks like discharge printing chemically remove dye from dark fabrics before replacing it with new pigment, creating prints that breathe with the fabric. Performance fabrics require low-cure additives to prevent damage to moisture-wicking properties, as documented.

Benefits of traditional screen printing

Traditional screen printing produces exact color matches using Pantone mixing systems, ensuring brand consistency across all printed materials. The process, according to industry analysis, scales efficiently for orders above 24 pieces with per-unit costs dropping significantly at higher volumes. Screen printed designs withstand industrial washing, making them perfect for work uniforms, team jerseys, and promotional items that face heavy use.

Why Choose Thrive Screen Printing in Peoria, AZ?

Thrive Screen Printing combines local market knowledge with professional printing capabilities to serve Peoria businesses and organizations. Our production facility maintains climate-controlled environments that ensure consistent ink curing despite Arizona’s temperature extremes. We stock popular garment styles and sizes specifically requested by Peoria clients, eliminating wait times for special orders.

Our local expertise and fast delivery times

Operating within Peoria means we understand local event schedules, from spring training merchandise to fall festival apparel needs. Our drivers deliver directly to Peoria businesses, schools, and event venues, eliminating shipping delays and damage risks common with out-of-state printers.

Customer support and design assistance

Every order receives dedicated support from our design team, who convert rough sketches into print-ready artwork at no additional charge. We provide digital mockups showing exactly how designs will appear on chosen garments, allowing revisions before production begins. Our team explains technical considerations like minimum line weights and color separations in plain language, ensuring first-time buyers achieve professional results.

Testimonials from Peoria clients

Local businesses consistently praise our reliability and quality. Youth sports organizations appreciate our flexible reorder system. School administrators value our educational pricing.

What Products Can You Customize with Screen Printing?

Screen printing adapts to numerous fabric surfaces and product types, from traditional apparel to specialty promotional items. The versatility of screen printing inks and techniques allows customization of virtually any fabric-based product, provided the surface can withstand the heat-curing process.

T-shirts, hoodies, polos, and hats

Cotton t-shirts remain the most popular screen printing canvas, accepting all ink types and producing vibrant results. Hoodies require special consideration for printing across seams and pockets, which we accommodate with oversized screens and careful placement. Polo shirts benefit from left-chest logos and subtle branding that maintains professional appearance, while structured hats need specialized equipment to print on curved surfaces without distortion.

Jerseys and team uniforms

Athletic jerseys demand performance inks that stretch with mesh fabrics without cracking during gameplay. We print player names and numbers using athletic-grade inks tested to withstand repeated washing at high temperatures. Team uniform packages include matching practice jerseys, warm-up gear, and fan apparel, all color-coordinated for cohesive team identity.

Bags, tote bags, and promotional items

Canvas tote bags accept screen printing beautifully, creating reusable promotional items that showcase brands for years. Drawstring sportspacks and gym bags expand marketing reach while providing practical value to recipients. Non-traditional items like bandanas, aprons, and rally towels offer unique branding opportunities for special events and trade shows.

Who Uses Screen Printing in Peoria — and Why?

Peoria’s diverse community generates steady demand for custom screen printing across multiple sectors. Each client segment requires specific considerations for design, durability, and delivery timelines that we’ve refined through years of local service.

Schools and school events

Elementary and high schools order spirit wear for fundraisers, with designs celebrating mascots and school pride. Field day shirts need bright colors and comfortable fabrics for outdoor activities in Arizona heat. Graduation commemorative apparel requires elegant designs that students will keep as mementos, often incorporating metallic inks or special effects.

Local businesses and employee apparel

Restaurants and retail stores outfit staff in branded apparel that withstands daily wear and commercial laundering. Construction companies need high-visibility safety shirts with reflective inks that meet ANSI/ISEA 107 standards. Professional service firms order embroidered polos combined with screen printed logos for a premium appearance.

Sports teams and recreational leagues

Youth soccer clubs order dozens of jerseys each season, requiring quick turnaround for late registrations. Adult softball leagues celebrate championships with commemorative shirts featuring team rosters and season statistics. Marathon training groups create motivational shirts for participants, often incorporating sponsor logos to offset costs.

Charities, fundraisers, and community events

Nonprofit organizations leverage screen printed merchandise for awareness campaigns and fundraising efforts. Walk/run events generate thousands of participant shirts requiring precise color matching to sponsor brands. Local festivals create limited-edition designs that become collectibles, driving additional revenue through merchandise sales.

What Is the Typical Screen Printing Process at Thrive?

Understanding our production process helps clients prepare effective artwork and set realistic timelines for their projects. Each step builds upon the previous one, ensuring quality control throughout production.

Design submission and file formats

Vector artwork in Adobe Illustrator format produces the sharpest screen printing results, though we accept various file types. High-resolution photographs require color separation to create distinct screens for each ink color. Our prepress team converts customer-supplied artwork into print-ready formats, identifying potential issues like thin lines or small text that won’t reproduce clearly.

Screens, ink selection, and test runs

Each color in your design requires a separate screen, created using photographic emulsion exposed with UV light. We mix inks to match Pantone colors exactly, ensuring brand consistency across all printed pieces. Test prints on actual garments verify color accuracy and placement before full production begins, allowing final adjustments without wasting materials.

Turnaround times and local delivery

Rush services accommodate urgent needs, though design complexity affects feasibility. Local delivery throughout Peoria and surrounding areas occurs with tracking provided for all orders.

How Much Do Screen Printing Services Cost?

Screen printing costs depend on multiple variables, which we explain transparently during the quoting process. Understanding these factors helps clients optimize designs for their budget while achieving desired results.

Cost per shirt and bulk pricing

Base garment costs range from $3-12 depending on brand, fabric quality, and style selected. Printing costs decrease significantly with volume, as industry pricing guides show setup expenses spread across more units. Orders exceeding 144 pieces qualify for wholesale garment pricing, providing additional savings.

Ink color counts and complexity factors

Each ink color requires a separate screen, adding $35 in setup costs per color according to industry pricing. Simple one-color designs on light garments offer the most economical option for budget-conscious buyers. Complex multicolor designs with tight registration or special effects like metallic inks increase both setup time and per-piece costs.

Setup fees and reorders

Initial screen creation represents a one-time investment that we store for future reorders. Repeat orders using existing screens eliminate setup fees entirely, making small reorders economically feasible. Design modifications require new screens, though minor text changes often utilize existing artwork elements to minimize costs.

What Makes Screen Printing Ideal for Arizona’s Climate?

Arizona’s extreme temperatures and intense UV exposure demand special consideration for printed apparel durability. Our ink formulations and curing processes specifically address these environmental challenges.

Durability in heat and sun exposure

Properly cured plastisol inks withstand surface temperatures up to 360°F without re-melting according to industry analysis. UV-resistant additives prevent color fading during extended outdoor exposure. Discharge inks actually dye fabric fibers, eliminating concerns about heat-activated adhesive failures.

Breathable fabrics and ink adhesion

Moisture-wicking performance fabrics require low-temperature curing to preserve their technical properties. We utilize catalyst additives that enable proper ink adhesion at reduced temperatures, preventing fabric damage. Mesh jerseys and athletic wear benefit from reduced ink deposits that maintain breathability while providing full color coverage.

Fade resistance in outdoor use

Outdoor workers and athletes subject printed apparel to extreme conditions requiring maximum durability. Fluorescent safety colors maintain ANSI-compliant visibility standards through repeated washing and sun exposure. White ink underbase layers protect designs on dark fabrics from UV penetration that causes premature fading.

Are There Eco-Friendly Screen Printing Options?

Environmental consciousness drives increasing demand for sustainable printing options in Peoria’s eco-aware market. We offer multiple approaches to reduce environmental impact without sacrificing quality or durability.

Water-based vs plastisol inks

Water-based inks contain no PVC or phthalates, using water as the primary solvent instead of petroleum products. These inks produce softer prints ideal for fashion applications, though they require different curing processes than traditional plastisol. Hybrid inks combine water-based and plastisol technologies, offering environmental benefits with enhanced durability for commercial applications.

Sustainable garment sourcing

Organic cotton and recycled polyester garments reduce environmental impact from raw material production. Fair-trade certified suppliers ensure ethical labor practices throughout the supply chain. American-made garments minimize transportation emissions while supporting domestic manufacturing, as documented by University of Michigan research.

Minimizing waste and excess materials

Precise ink mixing reduces leftover materials requiring disposal at job completion. Screen reclamation systems allow indefinite screen reuse, eliminating mesh waste. Digital mockups replace physical samples for approval processes, reducing test printing and garment waste.

How to Prepare and Submit a Screen Printing Order

Successful screen printing projects begin with proper preparation and clear communication of requirements. Following our proven ordering process ensures smooth production and on-time delivery.

Choosing garment styles and sizes

Size distribution planning prevents over-ordering unpopular sizes while ensuring adequate inventory for all participants. We provide size charts and fit guides for all garment brands, helping predict accurate quantities. Fabric weight considerations balance comfort preferences with durability requirements for intended use.

Uploading artwork and getting proofs

Our online portal accepts artwork uploads with automatic preflight checking for common issues. Digital proofs show exact placement and sizing on chosen garments before production begins. Virtual samples allow stakeholder approval without physical samples, accelerating the approval process.

Payment, pickup, and shipping options

Net terms available for established businesses simplify ordering for repeat clients. Credit card payments process securely through our online system for immediate order confirmation. Local pickup saves delivery fees while ensuring personal inspection of completed orders.

FAQs About Screen Printing in Peoria

What’s the average turnaround time for a screen printing order in Peoria?

Orders complete with fast turnaround from artwork approval.

Do you offer help with artwork or logo preparation?

Yes, Thrive provides full design assistance to prepare graphics for optimal printing results at no extra charge.

Is there a minimum order size?

Small-run pricing accommodates lower quantities when needed.

Can I bring my own garments for printing?

Customer-supplied garments are accepted after review for print compatibility and proper preparation requirements.

Are the inks you use eco-friendly?

We offer both traditional plastisol and eco-conscious water-based ink options to meet various sustainability goals.

What fabric types work best for screen printing?

Cotton and cotton-blend fabrics produce optimal results, though we successfully print on various synthetic materials using appropriate techniques.

Is Thrive Screen Printing locally owned?

Yes, we operate as a Phoenix-based business serving greater Phoenix with local expertise and community commitment.

Get Expert Screen Printing in Peoria Today

Transform your vision into professional custom apparel with Thrive Screen Printing’s proven expertise and local service advantage. Our combination of advanced printing technology, climate-specific ink formulations, and deep understanding of Peoria’s market needs ensures your project succeeds from concept through delivery. Contact us today for a free quote and discover why local businesses, schools, and organizations trust us for all their screen printing needs.