Screen printing services in Oro Valley provide businesses, schools, and organizations with professional custom apparel solutions for branding, events, and team identity. Whether you need vibrant t-shirts for a local fundraiser, durable uniforms for your Oro Valley business, or promotional merchandise for community events, professional screen printing delivers high-quality results that withstand Arizona’s unique climate conditions. We specialize in transforming your design ideas into bold, long-lasting prints that make your message stand out.

What Is Screen Printing and Why Is It Popular?

How does screen printing work?

Screen printing pushes ink through a mesh stencil onto fabric to create permanent designs. The process involves creating a separate screen for each color in your design, positioning the screen over the garment, and applying ink with a squeegee that forces color through the open areas of the mesh. This technique produces thicker ink deposits than digital printing methods, resulting in exceptional durability and color vibrancy that lasts through 50 wash cycles, according to a peer-reviewed study on screen printed textiles.

What makes it different from digital printing?

Screen printing excels for bulk orders because setup costs distribute across larger quantities, making per-unit prices highly competitive. Digital printing applies ink directly onto fabric without screens, which suits small runs or complex photographic designs. Screen printing remains the preferred method for large orders, particularly when designs feature solid colors and require maximum durability, according to Printify. Screen printed designs withstand industrial washing better than digital alternatives, making them ideal for work uniforms and athletic wear in Oro Valley’s active outdoor environment.

Common use cases: corporate, schools, teams & more

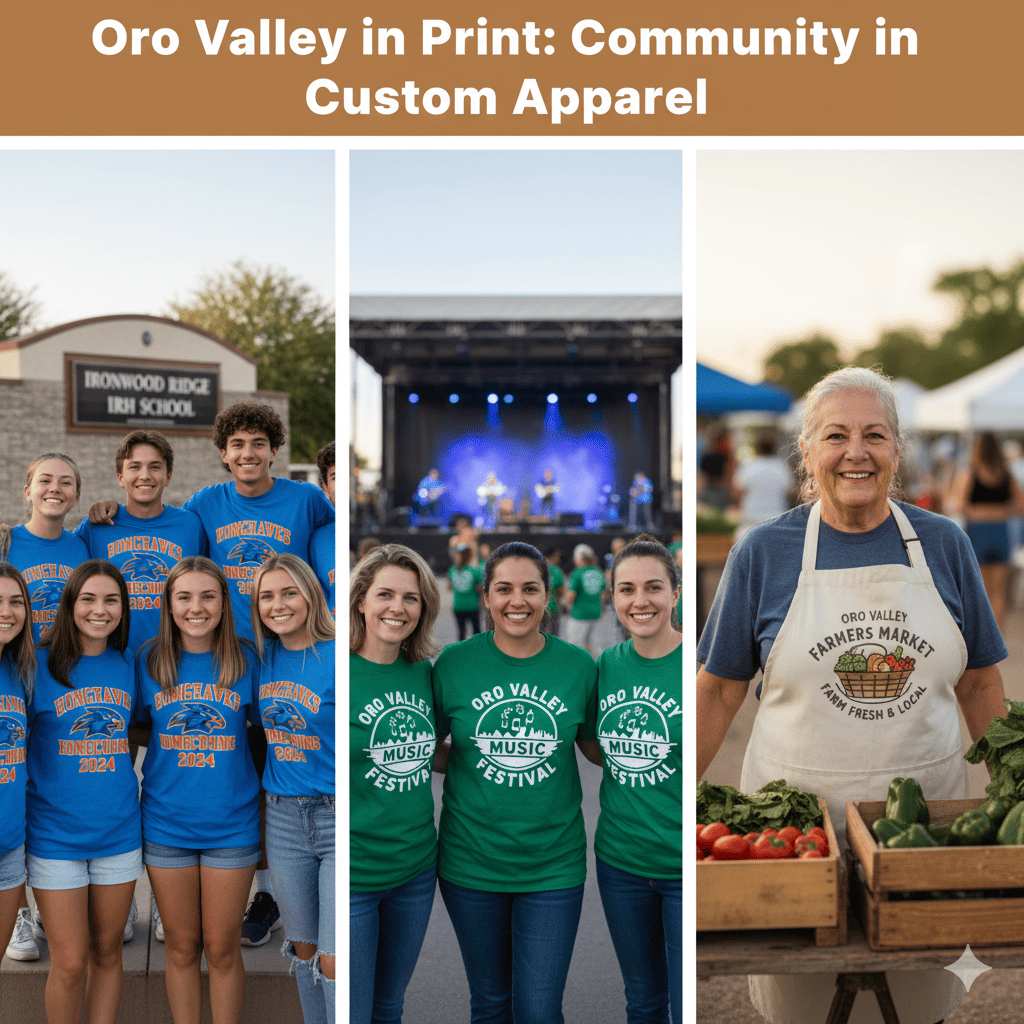

Oro Valley businesses rely on screen printing for employee uniforms that maintain professional appearance despite daily wear. Local schools including Ironwood Ridge High School and Canyon del Oro High School order spirit wear for students, staff, and supporters throughout the academic year. Youth sports leagues across Northwest Tucson choose screen printed jerseys for their durability during intense Arizona summer practices. Corporate clients from the Oro Valley Innovation Labs request branded merchandise for conferences and trade shows. Community organizations hosting events like the Oro Valley Music Festival utilize custom t-shirts for volunteers and attendees, creating unified visual identity while promoting their cause.

Why Choose Local Screen Printing in Oro Valley?

Climate, environment & ink durability considerations

Professional screen printers in Oro Valley use UV-resistant inks specifically formulated for desert climates, ensuring designs maintain their vibrancy despite prolonged sun exposure. Local expertise matters because printers understand how Oro Valley’s elevation of 2,620 feet affects ink drying times and adjust their processes accordingly, according to the Town of Oro Valley]

Community groups and event-based apparel needs

Oro Valley hosts numerous annual events requiring custom printed apparel, from the Oro Valley Winfield Trading Post Days to charity runs benefiting local causes. Community groups need reliable turnaround times to meet event deadlines, something distant printers often struggle to accommodate. Local screen printing services understand the seasonal patterns of Oro Valley events, maintaining adequate inventory of popular garment styles and colors during peak ordering seasons. We work directly with event coordinators to ensure designs reflect local culture and resonate with participants who call Northwest Tucson home.

Advantages of fast local turnaround times

Working with Oro Valley-based screen printing eliminates shipping delays and reduces your carbon footprint. Standard turnaround times range from 5-7 business days for most orders, with rush options available for time-sensitive projects. Local production means you can approve physical samples before full production begins, catching potential issues before they affect your entire order. Face-to-face consultations allow for real-time design adjustments and color matching against physical swatches.

What Products Can Be Screen Printed?

T-shirts, hoodies, uniforms

Cotton t-shirts remain the most popular screen printing canvas, with 100% cotton and cotton-polyester blends offering excellent ink adhesion. Hoodies present unique printing opportunities for chest designs, back graphics, and sleeve prints that showcase team or company identity. Work uniforms including polo shirts, button-downs, and safety shirts benefit from screen printing’s durability for logos and employee names. Performance fabrics used in athletic wear accept specialized inks that maintain flexibility during physical activity. We stock popular brands like Gildan, Bella+Canvas, and Port & Company to meet diverse style preferences and budget requirements.

Tote bags, promotional merchandise

Canvas tote bags serve as walking billboards for Oro Valley businesses and organizations, with screen printed designs lasting years of regular use. Promotional items including drawstring bags, bandanas, and rally towels extend brand visibility beyond traditional apparel. Screen printing adapts to various material surfaces including nylon, polyester, and cotton blends commonly used in promotional products. The Global Ad Impressions Study that screen printed promotional items generate over 6,100 impressions throughout their lifetime, providing exceptional marketing value for Oro Valley businesses.

Custom requests and specialty garments

Specialty printing projects showcase screen printing’s versatility beyond standard apparel. Aprons for Oro Valley restaurants feature multi-color logos that withstand commercial washing. Tank tops for fitness studios incorporate moisture-wicking fabrics with breathable ink applications. Youth sizes accommodate school programs and sports leagues serving Oro Valley’s growing family population. Oversized prints spanning entire garment surfaces create bold statement pieces for special events. Custom placement options include traditional chest prints, oversized back designs, sleeve prints, and hem tags that add professional finishing touches.

How Much Do Screen Printing Services Cost in Oro Valley?

Factors that affect pricing (volume, color count, design complexity)

Screen printing costs depend primarily on quantity ordered, with price breaks typically occurring at 24, 72, and 144 pieces. Each color in your design requires a separate screen, adding setup costs that distribute across your total order. Design complexity affects pricing when artwork requires color separations or halftone effects to achieve photographic quality. Garment quality significantly impacts final costs, with premium brands costing 40-60% more than standard options. Print locations beyond standard chest placement may incur additional charges for specialty equipment setup.

Average cost estimates for common orders

Based on industry pricing surveys, single-color prints on standard t-shirts are cost-effective for 50-piece orders in the Oro Valley market. Two-color designs on the same quantity include garment cost. Bulk orders of 144 pieces or more reduce per-unit costs for single-color prints on quality garments. Premium hoodies with multi-color prints are priced accordingly for moderate quantities. These estimates include standard turnaround times, with rush orders adding to base pricing.

Bulk and nonprofit discounts

Volume discounts reward larger orders with savings reaching 30% compared to small-run pricing. Nonprofit organizations registered in Arizona often qualify for additional discounts ranging from 10-15% off standard rates. School districts and educational institutions receive special pricing considerations for spirit wear and uniform programs. Repeat customers benefit from waived setup fees on reorders using existing screens. We maintain flexible pricing structures that accommodate Oro Valley’s diverse organizational needs while ensuring quality remains uncompromised.

What’s the Screen Printing Process at Thrive Screen Printing?

Design submission & proofing

Customers submit designs through our online portal accepting vector files (AI, EPS, PDF) for optimal print quality. High-resolution raster images (300 DPI minimum) work for simpler designs without fine details. Our design team reviews submissions within 24 hours, providing feedback on printability and suggesting optimizations if needed. Digital proofs show exact placement and sizing on selected garments before production begins. We offer complimentary design assistance for clients needing help converting concepts into print-ready artwork. Color matching services ensure brand consistency using Pantone color systems as reference standards.

Screen setup & production timeline

Screen creation begins once designs receive final approval, with each color requiring individual screen preparation. Screens undergo coating with light-sensitive emulsion before your design burns onto the mesh using UV exposure. Setup typically requires 2-3 business days depending on design complexity and current production schedules. Production runs average 2-4 days for standard orders under 200 pieces. Quality control checks occur throughout printing to maintain color consistency and placement accuracy. Curing processes lock inks permanently into fabric fibers using commercial conveyor dryers reaching 320°F.

Quality control & finishing steps

Every printed piece undergoes individual inspection for print quality, placement accuracy, and garment integrity. Test washes verify ink adhesion meets durability standards before order completion. Garments receive professional folding and packaging that protects prints during transport. Order documentation includes care instructions ensuring customers maintain print quality through proper washing. Final counts verify order accuracy with any defective pieces replaced before delivery. We photograph completed orders for quality records and customer approval when requested.

What to Expect When You Order from Thrive Screen Printing

Consultation and design help

Initial consultations explore your vision, timeline, and budget to recommend optimal solutions. We provide garment samples for touch-and-feel evaluation before ordering. Design consultations include advice on color selection for maximum visual impact. Mock-ups show how designs appear on different garment colors and styles. Experienced staff guide first-time customers through the entire process from concept to completion. We maintain extensive portfolios showcasing previous work for inspiration and reference.

Typical turnaround time

Standard orders complete within 7-10 business days from design approval to ready-for-pickup status. Rush services accommodate tight deadlines with 2-3 day turnaround available for additional fees. Reorders using existing screens often ship within 3-5 business days. Large orders exceeding 500 pieces may require extended timelines discussed during consultation. Seasonal peaks around back-to-school and holiday periods may affect standard timelines. We communicate proactively about production status throughout your order process.

Pick-up vs. delivery options

Our Oro Valley location offers convenient pickup during business hours with ample parking for easy loading. Local delivery serves businesses within a 15-mile radius for orders exceeding $250. Shipping options include ground and expedited services for out-of-area recipients. Bulk orders include complimentary local delivery within Oro Valley town limits. Split shipments accommodate multiple delivery locations for corporate accounts. All orders include tracking information for shipments and delivery confirmations for local drops.

How to Choose the Right Apparel for Your Custom Prints

Fabric types & their benefits

Cotton fabrics provide superior ink absorption resulting in vibrant, long-lasting prints ideal for everyday wear. Polyester blends offer moisture-wicking properties perfect for athletic applications and outdoor events. Tri-blend materials (cotton/polyester/rayon) create ultra-soft garments with vintage appeal popular for retail and fashion applications. Performance fabrics require specialized ink formulations but deliver prints that stretch without cracking during physical activity.

Fit guides for shirts & hoodies

Modern athletic fits taper through the body appealing to younger demographics and fitness-oriented organizations. Classic fits provide comfortable room without excess fabric, suitable for diverse body types across age ranges. Ladies’ cuts feature tailored waists and shorter sleeves designed specifically for feminine silhouettes. Youth sizing spans from toddler through teen with proportions adjusted for growing bodies. Size sampling before bulk orders ensures proper fit across your entire group. We maintain comprehensive size charts with actual garment measurements rather than just standard S-M-L-XL designations.

Eco-friendly garment options

Sustainable apparel options include organic cotton grown without pesticides and certified by Global Organic Textile Standard. Recycled polyester garments divert plastic waste while maintaining performance characteristics. Water-based inks provide eco-friendly printing alternatives with softer hand-feel and reduced environmental impact. Bamboo-blend fabrics offer natural antimicrobial properties with sustainable sourcing. Carbon-neutral shipping options offset transportation emissions for environmentally conscious organizations. We prioritize suppliers demonstrating commitment to ethical manufacturing practices and fair labor standards.

Screen Printing Regulations and Best Practices in Arizona

Compliance with local business codes

Arizona businesses must maintain proper licensing for commercial screen printing operations per Arizona Department of Revenue requirements. Transaction privilege tax licenses cover retail sales of printed merchandise within Oro Valley jurisdiction. Environmental regulations govern proper disposal of screen cleaning chemicals and ink waste. Workplace safety standards mandate adequate ventilation for printing areas and proper protective equipment for employees. Copyright compliance requires written permission before reproducing trademarked logos or copyrighted designs. We maintain all required permits and insurance coverage protecting both our operation and client interests.

Eco-friendly inks and wash safety

Water-based inks reduce volatile organic compounds (VOCs) compared to traditional plastisol formulations according to EPA guidelines]. Discharge printing removes garment dye rather than adding layers, creating soft prints without plastic feel. Proper curing temperatures ensure prints withstand recommended washing without releasing microplastics. Care instructions specify cold water washing and air drying to maximize garment lifespan. Low-cure additives reduce energy consumption during production while maintaining durability standards. We offer eco-friendly options for environmentally conscious clients without compromising print quality.

Trademark/logo usage policies

Proper licensing documentation protects against trademark infringement when printing corporate logos or branded content. Schools and universities often require approved vendor status before authorizing official merchandise production. Sports leagues including Little League and Pop Warner maintain strict guidelines for team apparel bearing official marks. Copyright releases from designers or artists must accompany custom artwork submissions. Fair use exemptions apply to parody or commentary designs following specific legal criteria. We verify proper authorizations before producing potentially protected content, maintaining records for client protection.

Local Success Stories and Client Spotlights

School spirit wear for Oro Valley High

Local high schools generate substantial spirit wear demand throughout the academic year for students, parents, and alumni. Recent projects include 500-piece orders for homecoming shirts featuring school colors and custom graphics celebrating campus traditions. Athletic departments order team-specific designs for each sport season, with basketball warm-ups and track uniforms requiring specialized performance inks. Parent booster clubs coordinate bulk orders for playoff support gear, often with 48-hour turnaround needs. We maintain approved vendor status with local school districts, streamlining the ordering process for administrators.

Branded shirts for local festivals and markets

The Oro Valley Farmers Market features over 50 vendors wearing custom printed shirts that identify their businesses to shoppers. Festival organizers for events like Music Under the Stars order volunteer shirts distinguishing staff from attendees. Food truck operators request aprons and t-shirts that withstand commercial kitchen environments while promoting their mobile businesses. Craft fair participants use branded apparel to create professional booth presentations attracting customer attention. These recurring events generate repeat business as organizations update designs annually while maintaining brand recognition.

Corporate uniforms for small businesses

Oro Valley’s growing business community includes tech startups, medical practices, and service companies requiring professional branded apparel. Recent corporate projects include 200-piece uniform programs for expanding HVAC companies serving Northwest Tucson. Medical offices order scrubs with embroidered logos complementing screen printed practice information. Restaurant groups standardize employee appearance across multiple locations with consistent branded apparel. Professional services firms request polo shirts for client-facing staff that project competence and reliability. We accommodate ongoing uniform needs with streamlined reorder processes and consistent quality standards.

How Does Screen Printing Compare to Embroidery or Heat Transfer?

Pros and cons of each

Screen printing excels for bold designs with solid colors on flat surfaces, offering unmatched durability and cost-effectiveness for larger quantities. Embroidery adds dimensional texture ideal for professional polos and hats but limits design complexity and increases per-unit costs. Heat transfer methods including vinyl and sublimation work well for small quantities or full-color photographic designs but may lack screen printing’s longevity.

Which is best for your needs?

Design characteristics guide decoration method selection more than personal preference. Simple logos with 1-4 colors achieve optimal results through screen printing’s vibrant ink deposits. Complex gradients or photographic images require digital printing or sublimation techniques. Small text under 0.25 inches height reproduces better through embroidery’s precise needle control. Mixed decoration combining screen printing with heat-applied elements creates unique effects for fashion-forward designs. Budget constraints often favor screen printing for community events and fundraisers maximizing per-dollar impact.

Durability and washability

Laboratory testing by the American Association of Textile Chemists and Colorists demonstrates properly cured screen prints withstand 50+ wash cycles without significant degradation, according to a peer-reviewed study. Embroidery maintains structural integrity indefinitely but may experience thread loosening without proper backing materials. Screen printing’s thick ink deposits resist abrasion better than thin heat transfer layers during active wear. Commercial laundry environments with high-temperature washing particularly favor screen printing’s robust chemical bonds.

Ready to Print? Here’s How to Get Started

Design tips for beginners

Successful screen printing designs utilize bold lines and clear contrast between elements and background colors. Vector graphics created in Adobe Illustrator or similar programs scale infinitely without quality loss. Text smaller than 0.5 inches height may lose readability, especially with script fonts or fine serifs. Negative space within designs should exceed 0.125 inches to prevent ink bleeding between elements. Color counts directly impact pricing, so consider design variations using strategic color combinations. We provide design templates showing safe print areas for various garment styles and sizes.

File types accepted

Vector formats including AI, EPS, and PDF preserve design quality regardless of scaling requirements. High-resolution raster files (PNG, JPG, PSD) work for simpler designs when saved at 300 DPI or higher at actual print size. Native design files allow our team to make minor adjustments optimizing printability. Hand-drawn sketches can be professionally digitized for additional fees. Logo files from previous print projects may require updating to meet current production standards. We offer file conversion services ensuring your vision translates perfectly to printed garments.

Contact and ordering process

Initial inquiries through our website or phone receive responses within one business day outlining project feasibility and estimated costs. Quote requests including quantity, garment preferences, and design details generate formal proposals within 24-48 hours. Order placement requires 50% deposits with remaining balance due upon completion. Online customer portals track order progress from design approval through production and delivery. Repeat customers access streamlined reorder systems maintaining previous specifications and pricing. We accept multiple payment methods including corporate accounts for qualified businesses.

Get Expert Screen Printing in Oro Valley Today

Transform your design vision into professional custom apparel with Thrive Screen Printing’s proven expertise in the Oro Valley market. Our combination of cutting-edge equipment, experienced staff, and commitment to customer satisfaction delivers results that exceed expectations while meeting your timeline and budget requirements. Contact us today at 602-607-2171 to start your custom screen printing project and join hundreds of satisfied Oro Valley customers who trust us for their branded apparel needs.